Thin gauge high-manganese high-aluminum steel with ultra-fine grain sizes and production method

A technology of ultra-fine grain and production method, which is applied in the production field of high-manganese and high-aluminum steel with ultra-fine grain size and thin specification, and can solve problems such as lack of large-scale production, low strength and strong plastic product, and complex production process. , to achieve the effects of short annealing time, microstructure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below:

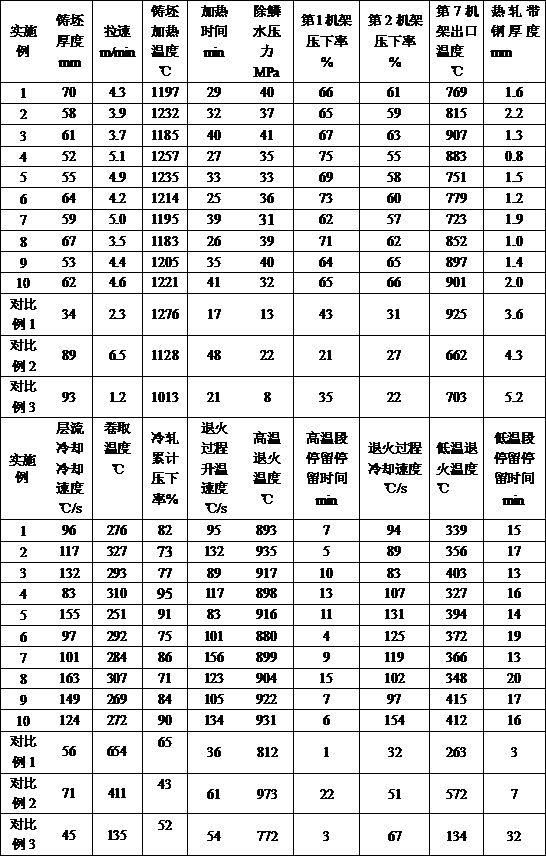

[0046] Table 1 is the composition value list of each embodiment of the present invention and comparative example;

[0047] Table 2 is the list of main process parameters of each embodiment of the present invention and comparative examples;

[0048] Table 3 is the main performance list of each embodiment of the present invention and comparative examples;

[0049] Table 4 is a list of special mold powder parameters for each embodiment and comparative example of the present invention.

[0050] Each embodiment of the present invention is produced according to the following preparation methods:

[0051] 1) Smelting and continuous casting into slabs. During the casting process, the casting speed is controlled at 3.5~5.1m / min, and the thickness of the slabs is controlled at 52~70mm;

[0052] 2) Heating the billet in the tunnel furnace, controlling the heating temperature at 1183~1257°C, and the heating time at 25~41min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com