Deformation adaptability wall lime shoveling device of water spraying type self-cleaning mechanism

A self-cleaning, water-spraying technology, used in building structures, machine tools suitable for grinding workpiece planes, and the use of liquid separators. and cleaning efficiency, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

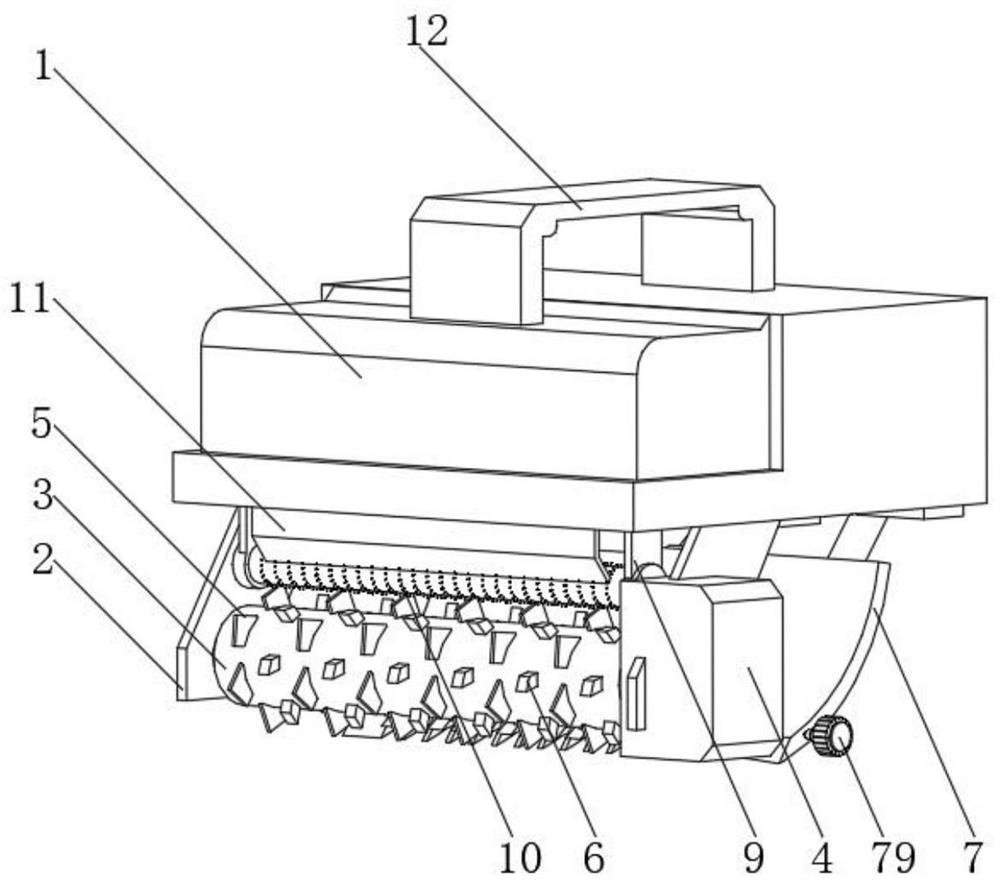

[0035] see Figure 1-3 , the present invention provides a technical solution: a deformation-adaptive wall ash shoveling device of a water spray type self-cleaning mechanism, comprising an ash shovel work box 1, a cleaning roller frame 2 is arranged at the bottom of the front side of the ash shovel work box 1, and the cleaning roller The inside of the frame 2 is equipped with a cleaning drum 3, the outside of the cleaning drum 3 is provided with a shoveling roller 3, the outside of the cleaning roller 3 is provided with a shoveling sheet 5 and a cleaning block 6, and the cleaning drum frame 2 side is provided with a driving motor box 4, which drives A cleaning roller motor is installed inside the motor box 4, and the output shaft of the cleaning roller motor passes through a coupling and the cleaning drum 3. An ash shovel mechanism 7 is installed at the rear bottom of the ash shovel work box 1, and an ash shovel mechanism 7 is installed on the rear side of the ash shovel work bo...

Embodiment example 2

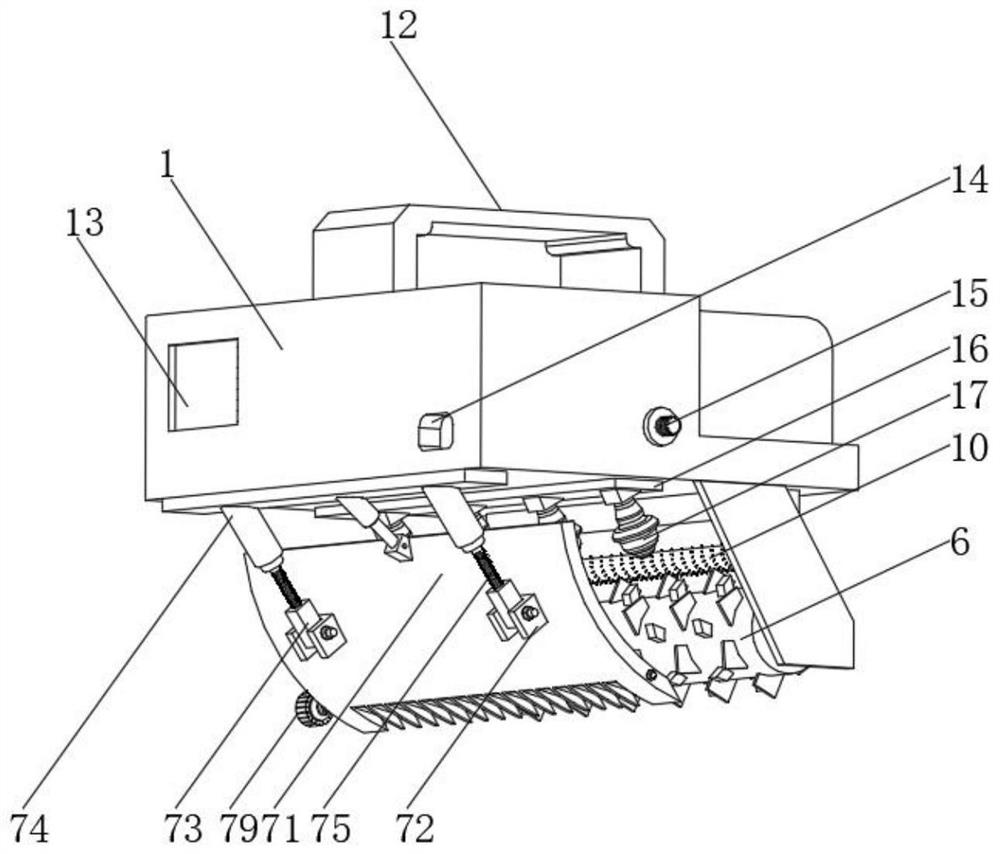

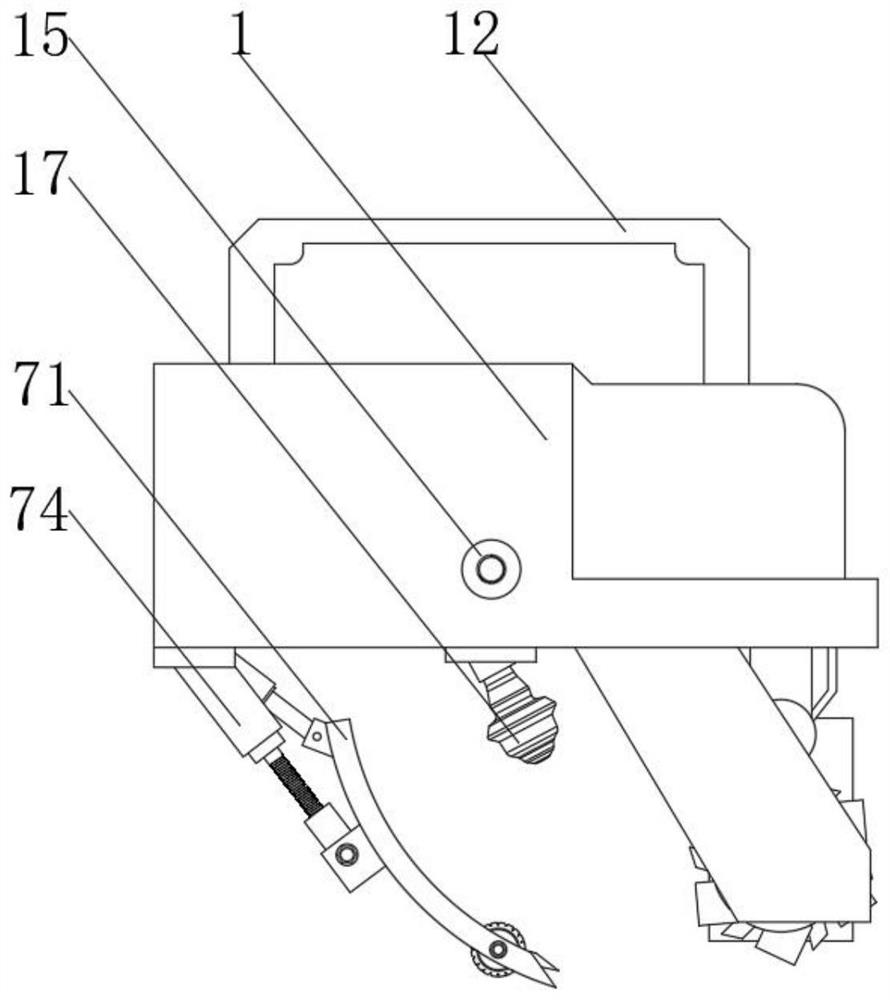

[0041] see Figure 1-6 , the present invention provides a technical solution on the basis of the implementation case 1: the ash shovel mechanism 7 includes a shovel plate 71, a connecting frame 72 is arranged on the rear side of the shovel plate 71, and a rotating inner frame 73 is rotatably connected inside the connecting frame 72, and the ash shovel The bottom of the work box 1 is equipped with a connecting column 74, and the bottom of the connecting column 74 is provided with a threaded rod 75. The bottom end of the threaded rod 75 is threadedly connected with the rotating inner frame 73. The bottom of the shovel plate 71 is provided with a shovel head 76, and the shovel head 76 Offer shoveling head slot 77, between shoveling head 76, rotating shaft is installed, and shoveling ash plug 78 is installed on the outside of rotating shaft, and shoveling ash plug 78 is installed between shoveling head groove 77.

[0042] The rotating shaft extends to the outside of the shoveling ...

Embodiment example 3

[0045] see Figure 7-8 , the present invention provides a kind of technical scheme on the basis of implementation case 1: grinding mechanism 8 comprises electric telescoping rod 81, and the bottom of electric telescopic rod 81 is equipped with grinding motor box 82, and grinding motor box 82 is internally equipped with grinding motor, and grinding motor output The shaft is equipped with a hexagonal grinding disc 83, the bottom of the hexagonal grinding disc 83 is provided with an outer hexagonal deformation grinding protrusion 84 and an inner hexagonal deformation grinding protrusion 85, and the middle position of the bottom of the hexagonal grinding disc 83 is provided with an inner grinding bar 86, The hexagonal grinding disc 83 is used for shoveling and grinding the walls. The hexagonal grinding disc design can clean up the side wall ash faster, and the hexagonal grinding disc is equipped with six deformation grinding protrusions and inner grinding The strips smooth the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com