Automatic inspection and intelligent remote control petroleum and natural gas wellhead valve and method

An oil and gas, remote control technology, applied in the field of oil and gas wellhead valves, can solve the problems of on-site operator injury, high labor cost, manual switch, etc., and achieve the effect of reducing labor, reducing working pressure, and reducing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

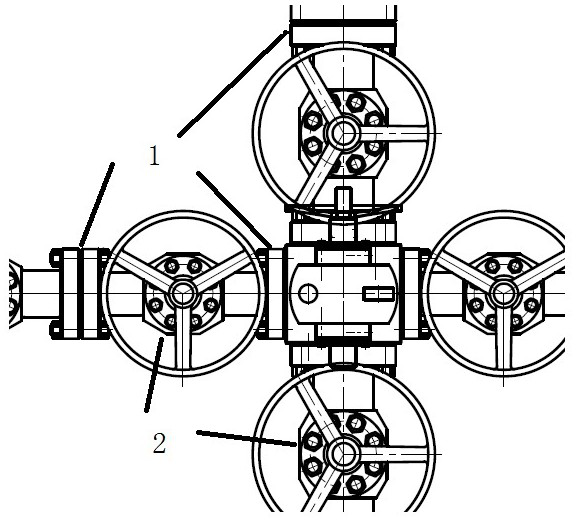

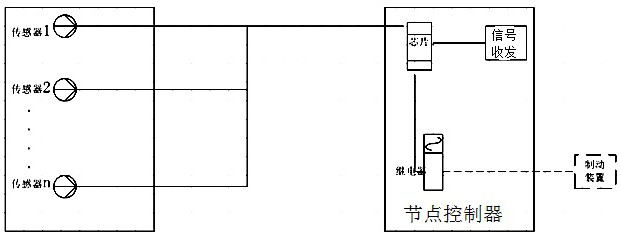

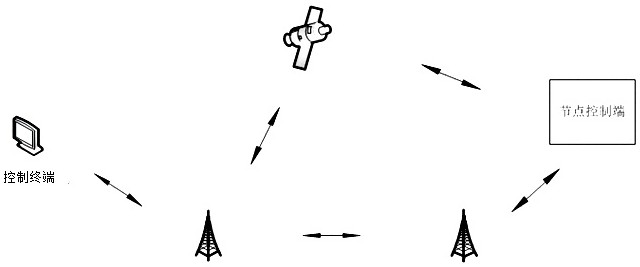

[0028] Such as Figure 1-3 Shown: An oil and gas wellhead valve with automatic inspection and intelligent remote control of the present invention includes a valve body and a power supply module. An annular steel ring is set at the connection between the valve body and the pipeline, and the annular steel ring is evenly distributed. Arranged with a pressure sensor 1, the pressure sensor is connected to the node controller 2, the node controller controls the braking device of the valve through the relay, the node controller is connected to the control terminal through the network or satellite signal, and the power supply module is used for Supply power to pressure sensors, node controllers, brake devices of valves, and node controllers.

[0029] For the oil and gas wellhead valve with automatic inspection and intelligent remote control, the power supply module adopts a solar photovoltaic panel power supply device, including a solar cell group and a storage battery connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com