Multi-objective optimization method based on fusion of Dynaform and intelligent algorithm

A multi-objective optimization and intelligent algorithm technology, applied in multi-objective optimization, multi-objective optimization based on the fusion of Dynaform and intelligent algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

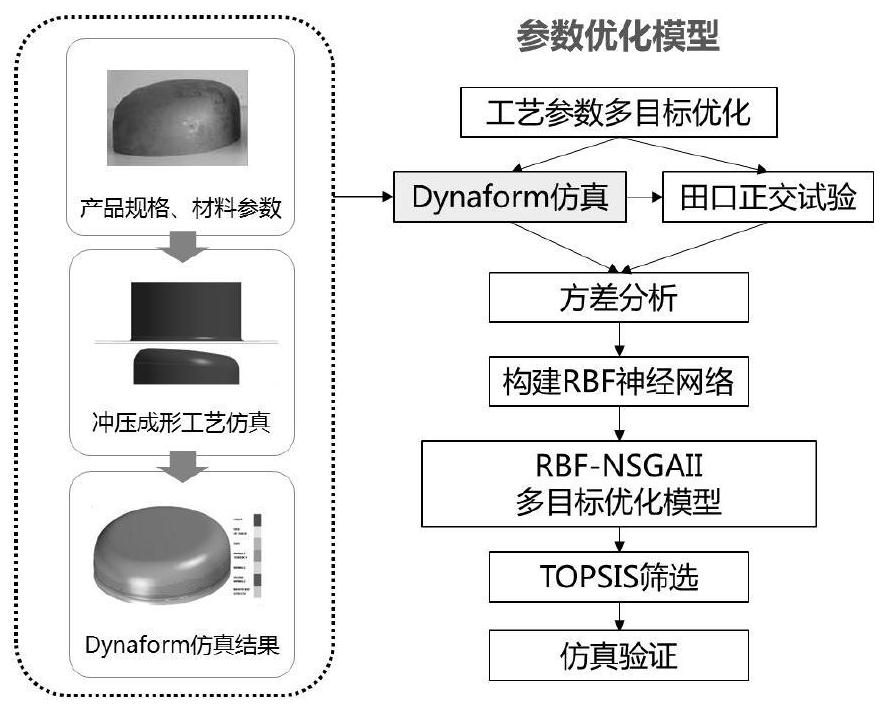

[0139] A multi-objective optimization method based on the fusion of Dynaform and intelligent algorithms, comprising the following steps:

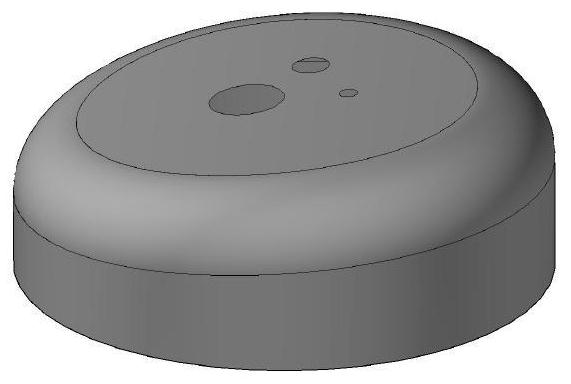

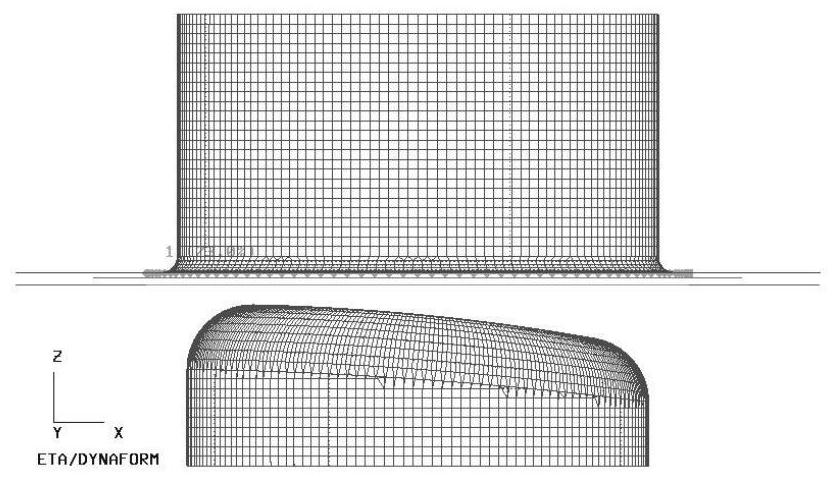

[0140] (1) Numerical simulation of stamping forming process: establish a computer-aided design model, and use the finite element analysis software Dynaform to perform numerical simulation of stamping forming, map the physical process of stamping forming, establish a finite element network in Dynaform, and divide the network;

[0141] (2) Use the Dynaform grid repair ModelCheck / Repair tool to compare and check the part boundary and the actual boundary, use the Overlap tool to check the overlapping unit, use the CursorPickPart tool to check the normal direction of the unit, and through the drawing process of the punch and the sheet, Obtain the finite element model of sheet metal stamping process;

[0142] (3) Orthogonal test design: 5 parameters of stamping speed, friction coefficient, blank holder force, sheet thickness, and die gap are sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com