Preparation method and application of self-supporting hierarchical porous carbon materials based on star-like block copolymers

A block copolymer, self-supporting technology, applied in the preparation/purification of carbon, the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. Micellar instability, unfavorable electrospinning operation, etc., to achieve the effect of good application prospects, narrow dispersion, and narrow versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

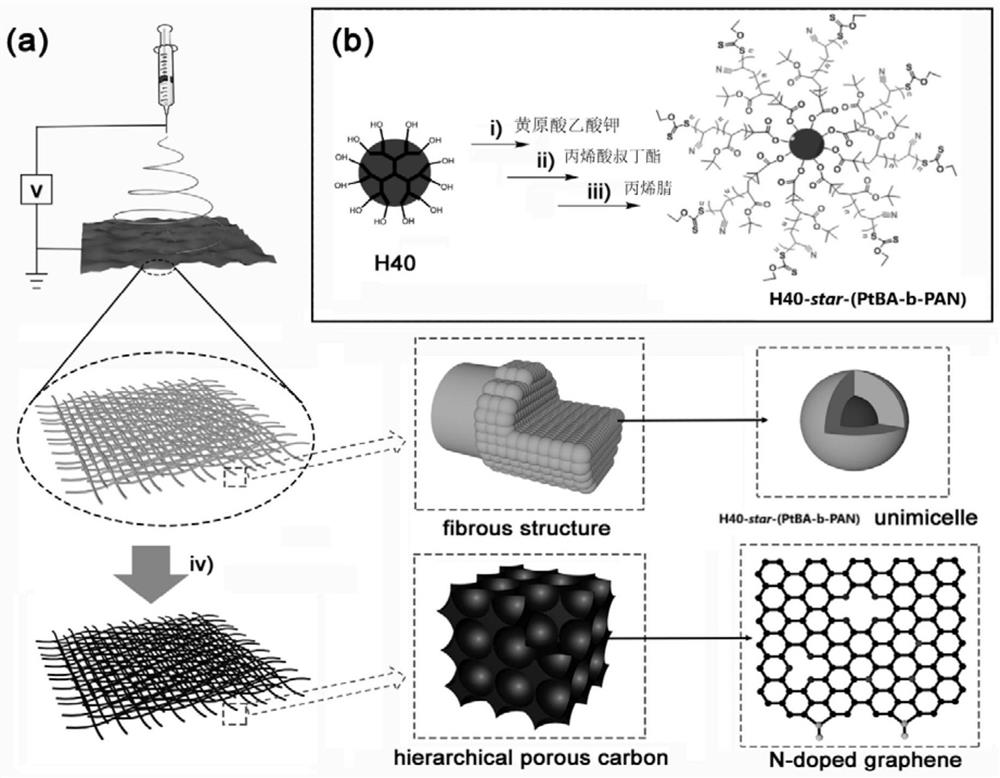

[0048] A preparation method and application of a self-supporting hierarchical porous carbon material based on a star-shaped block copolymer, such as figure 1 As shown, the specific steps are as follows:

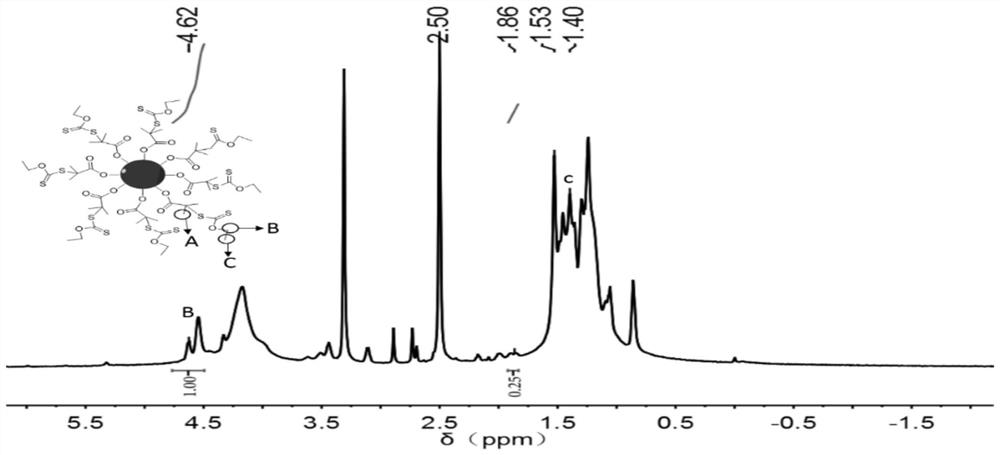

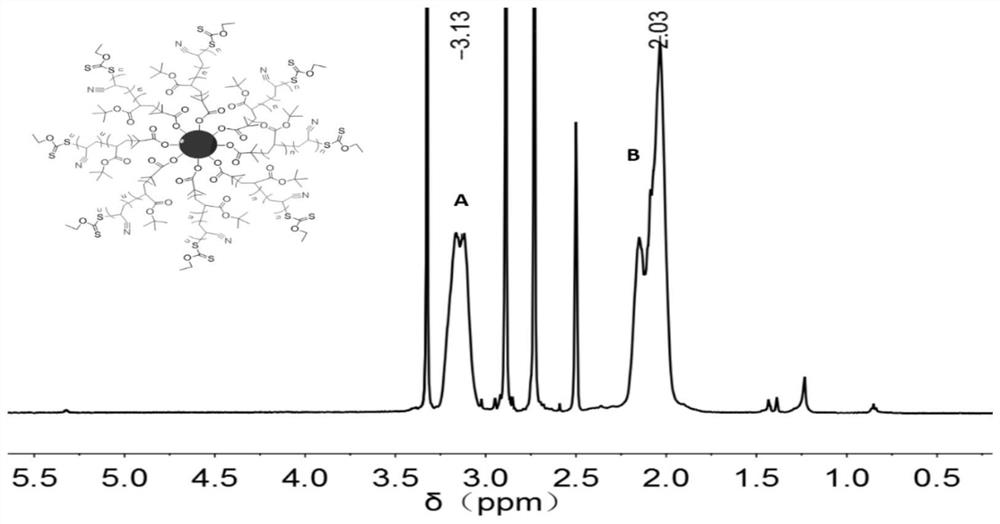

[0049] Under nitrogen protection, BoltonH40 (1.325g, 0.3mmol) was put into a vacuum oven at 80°C for drying overnight before the reaction, and added to a Schlenk bottle equipped with a magnetic stirrer with 60mL of N-methylpyrrolidone. Keep the solvent at 0°C under ice-bath conditions, slowly add 2-bromoisobutyryl bromide (2.214g, 19.2mmol), and maintain at 0°C for 2 hours, then rise to room temperature, react for 22 hours, and get light yellow after reaction The liquid is extracted with dichloromethane and saturated sodium carbonate solution, and the liquid in the lower part of the extraction bottle obtained is packed into an eggplant-shaped bottle and rotated under the rotary evaporation system of a circulating water vacuum pump to obtain a yellow viscous liquid. A white s...

Embodiment 2

[0060] A preparation method and application of a self-supporting hierarchical porous carbon material based on a star-shaped block copolymer, such as figure 1 As shown, the specific steps are as follows:

[0061]Under the protection of nitrogen, put BoltonH40 (1.325g, 0.3mmol) into a vacuum oven at 80°C for drying overnight before the reaction, and add 60mL of N-methylpyrrolidone into a Schlenk bottle equipped with a magnetic stirrer, Keep the solvent at 0°C under ice-bath conditions, slowly add 2-bromoisobutyryl bromide (2.214g, 19.2mmol), and maintain at 0°C for 2 hours, then rise to room temperature, react for 22 hours, and get light yellow after reaction The liquid is extracted with dichloromethane and saturated sodium carbonate solution, and the liquid in the lower part of the obtained extraction bottle is packed into an eggplant-shaped bottle and rotated under the rotary evaporation system of a circulating water vacuum pump to obtain a yellow viscous liquid. A white soli...

Embodiment 3

[0068] A preparation method and application of a self-supporting hierarchical porous carbon material based on a star-shaped block copolymer, such as figure 1 As shown, the specific steps are as follows:

[0069] Under the protection of nitrogen, put BoltonH40 (1.325g, 0.3mmol) into a vacuum oven at 80°C for drying overnight before the reaction, and add 60mL of N-methylpyrrolidone into a Schlenk bottle equipped with a magnetic stirrer, Keep the solvent at 0°C under ice-bath conditions, slowly add 2-bromoisobutyryl bromide (2.214g, 19.2mmol), and maintain at 0°C for 2 hours, then rise to room temperature, react for 22 hours, and get light yellow after reaction The liquid is extracted with dichloromethane and saturated sodium carbonate solution, and the liquid in the lower part of the extraction bottle obtained is packed into an eggplant-shaped bottle and rotated under the rotary evaporation system of a circulating water vacuum pump to obtain a yellow viscous liquid. A white sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com