A high-efficiency cooling and heat-dissipating device for a clad power cabinet

A technology for heat dissipation device and power cabinet, which is applied to the substation/distribution device casing, the cooling/ventilation of the substation/switchgear, and the details of the substation/switch layout, etc. and other problems, to achieve the effect of improving heat dissipation efficiency and improving the speed of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

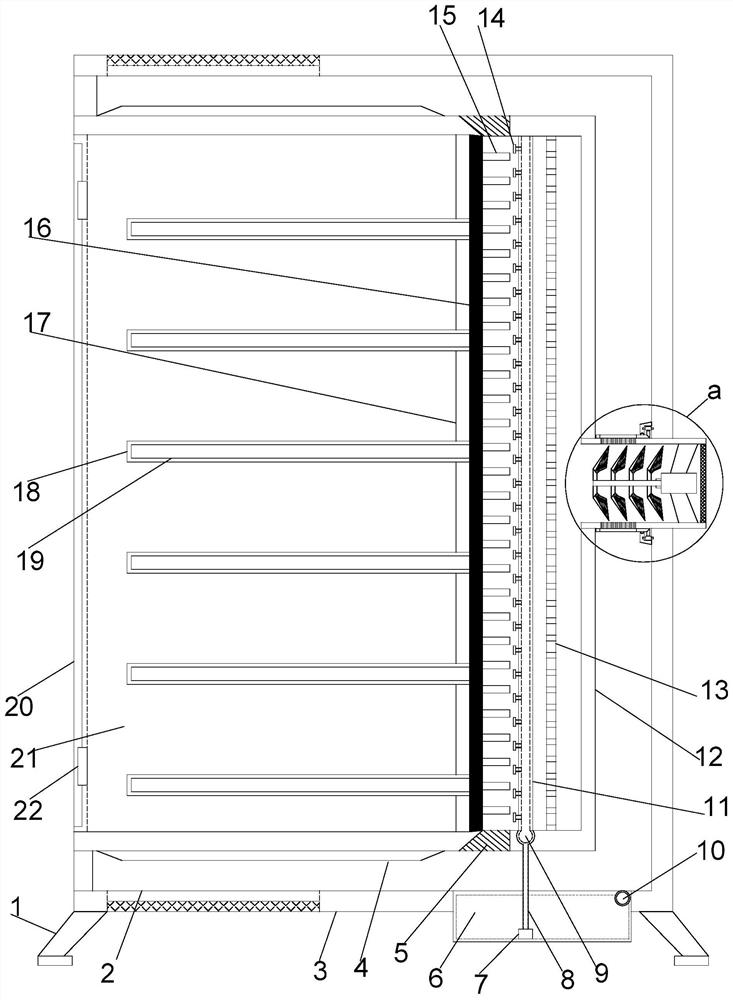

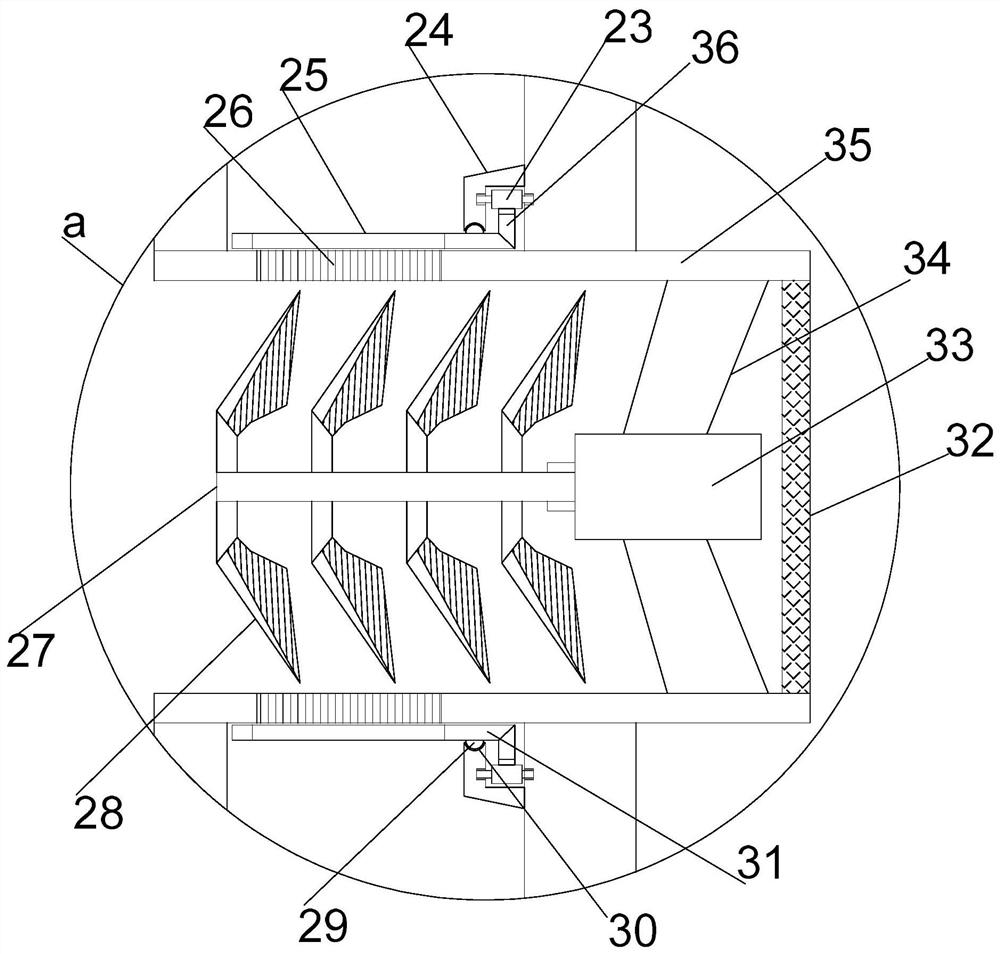

[0021] see Figure 1~3 , in an embodiment of the present invention, an efficient cooling and cooling device for a covered power cabinet includes a vertically arranged support installation cylinder 3, and support installation columns 1 are provided at the four corners of the lower end of the support installation cylinder 3, and the inside of the support installation cylinder 3 The middle position is provided with a fixed installation cylinder 21, the left side of the fixed installation cylinder 21 is connected with the support installation cylinder 3, and the left end of the fixed installation cylinder 21 is equipped with a rotary gate 20 through a hinge 22 arranged symmetrically up and down, and the inside of the fixed installation cylinder 21 The right side is vertically provided with a heat insulating plate 17, the right side of the heat insulating plate 17 is provided with a heat conducting plate 16, and the left side of the heat insulating plate 17 is equidistantly provided...

Embodiment 2

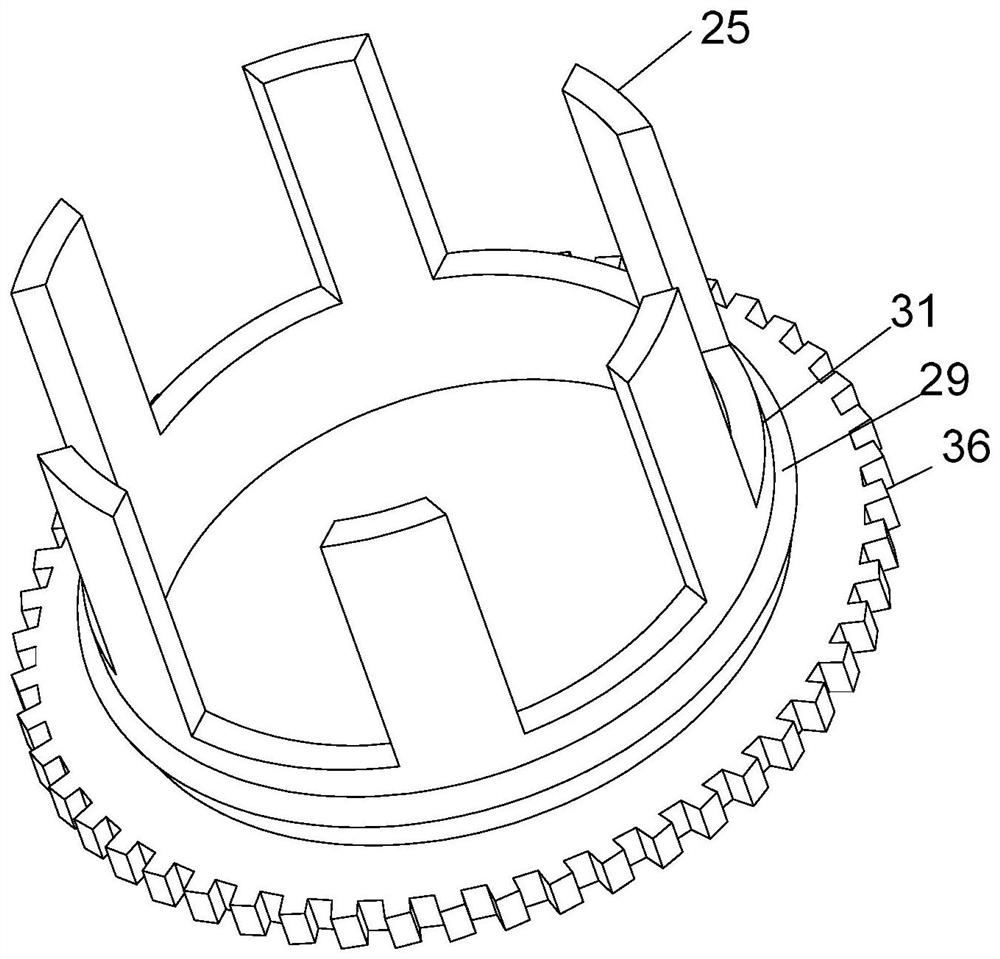

[0024] On the basis of Embodiment 1, when the driving gear 23 meshes with the rotating gear ring 36, the rotating mounting ring 31 rotates. At this time, the misalignment guide hole 26 and the misalignment guide plate 25 are misaligned or closed, thereby controlling the internal air. The efficiency of air diversion allows the air to be directly blown through the heat conduction fins, enabling the device to perform heat dissipation under low load conditions and adapt to different heat dissipation requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com