A kind of electrolytic preparation optimization method of potassium ferrate

An optimization method, potassium ferrate technology, applied in the direction of electrolysis components, electrolysis process, electrode shape/type, etc., can solve the problems of large power consumption and low current efficiency, and achieve extended service life, high current efficiency, and reduced resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

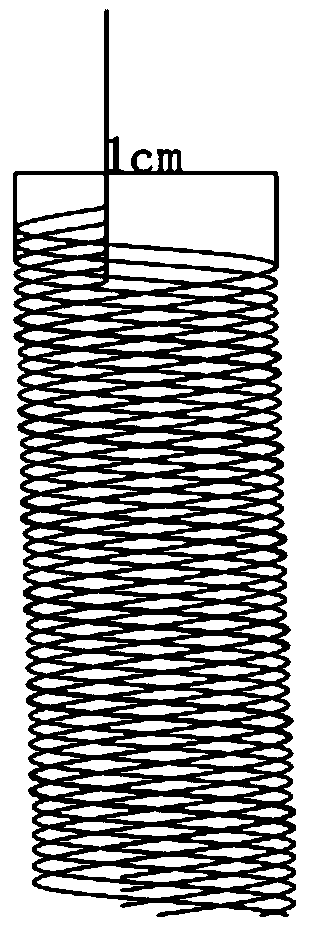

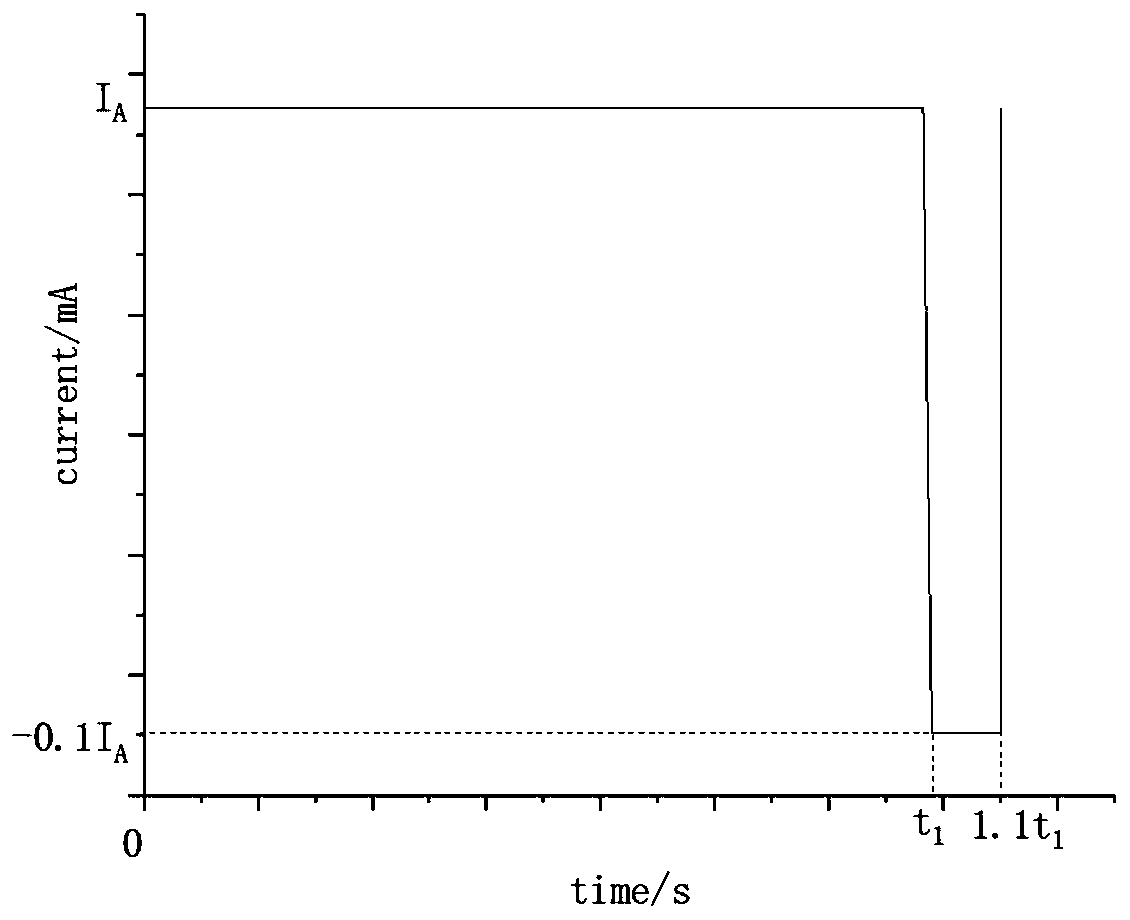

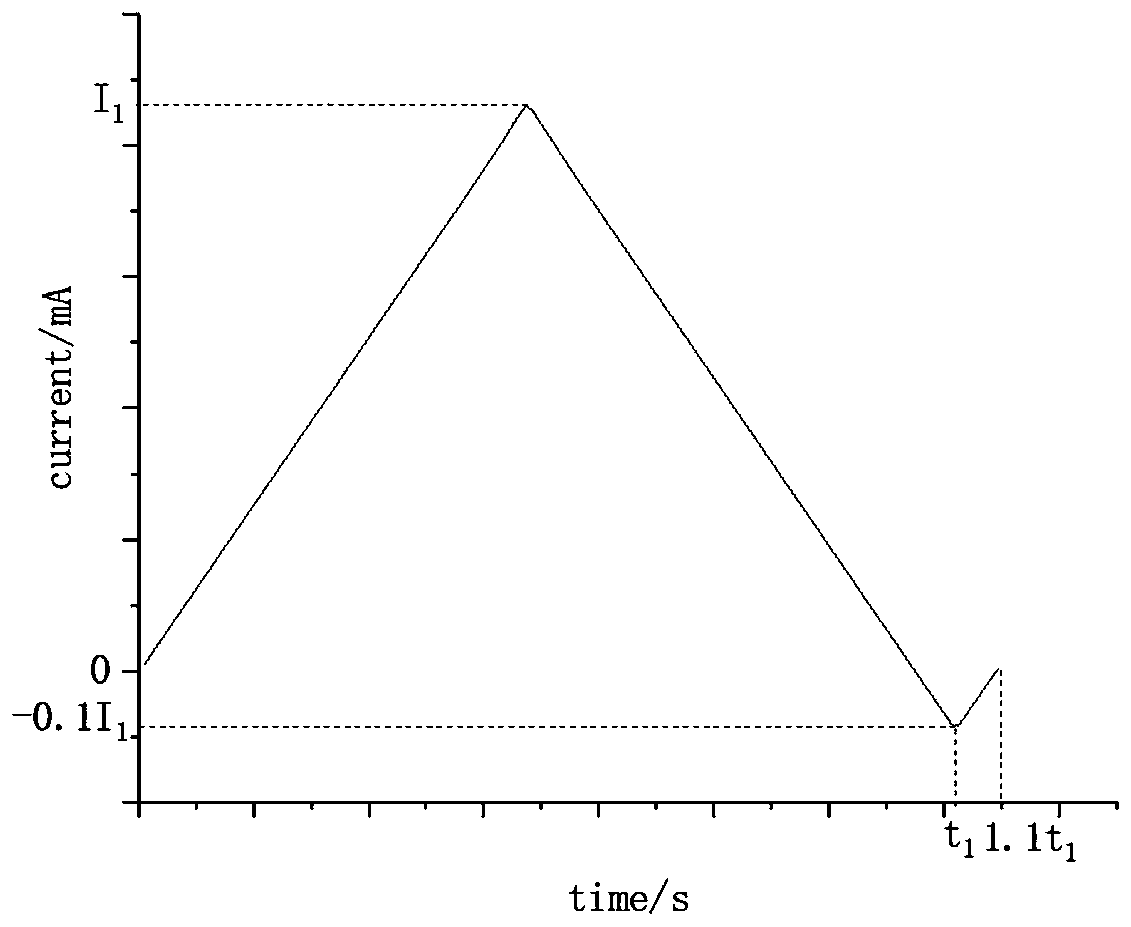

Embodiment 1

[0047] First, 14mol / L NaOH solution was injected into the cathode chamber and the anode chamber respectively, and about 70mL of electrolyte was added to the anode chamber; 130mL was added to a single cathode chamber. Then place the electrolytic cell in a constant temperature water bath at 40°C. The anode uses ten iron wires with a diameter of 0.3mm, each with a length of about 90cm, wound into a hollow spiral cylinder, the hollow diameter is 1cm, and the number of turns of the iron wire is 26 turns. Around, the effective immersion area is about 84.82cm 2 , the cathode is a platinum electrode of 10mm*10mm*0.1mm. A square wave alternating current with a period of 15s is superimposed on the electrode (such as figure 2 ), the positive pulse current is 933.05mA, and the duration of a single cycle is 13.6364s; the negative pulse current is -93.305mA, and the duration of a single cycle is 1.3636s. Finally, 1 mL of anolyte was taken every hour to measure the concentration of ferrat...

Embodiment 2

[0051] In the anolyte of embodiment 1, add 0.01mol / LNaH 2 PO 4 , the rest of the conditions are the same as in Example 1, and the calculated electrosynthesis rate is 8.368g L -1 / h -1 Table 2 shows the ferrate concentration and current efficiency per hour in Example 2.

[0052] Electrolysis time / h 1h 2h 3h 4h 5h 6h CNa2Fe04(mol / L 0.0556 0.0938 0.139 0.174 0.2102 0.2006 Current efficiency% 73.43 60.187 57.7 52.5 49.05 37.87

[0053] Table 2.

Embodiment 3

[0055] First, use tap water to configure 16mol / L NaOH solution and inject it into the cathode chamber and the anode chamber respectively, of which about 70mL electrolyte is added to the anode chamber, and 0.015mol / L NaH is added to the anode chamber at the same time 2 PO 4 Add 130mL to a single cathode chamber, and then place the electrolytic cell in a constant temperature water bath at 40°C. The anode uses ten iron wires with a diameter of 0.3mm, each with a length of about 90cm, wound into a hollow spiral cylinder, and the hollow diameter is 1cm , the number of iron wire turns is about 26 turns, and the effective immersion area is about 84.82cm 2 , the cathode is a platinum electrode of 10mm*10mm*0.1mm. A square wave alternating current with a period of 15s is superimposed on the electrode (such as figure 2 ), the positive pulse current is 933.05mA, and the duration of a single cycle is 13.6364s; the negative pulse current is -93.305mA, and the duration of a single cycle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com