pneumatic tire

A pneumatic tire, tire circumferential technology, applied in the direction of special tires, tire parts, tire tread/tread pattern, etc., can solve the problems of wear resistance, durability reduction, difficulty in balancing, and deterioration of rolling characteristics, etc. Achieves the effect of maintaining durability, good physical properties, and a good balance of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

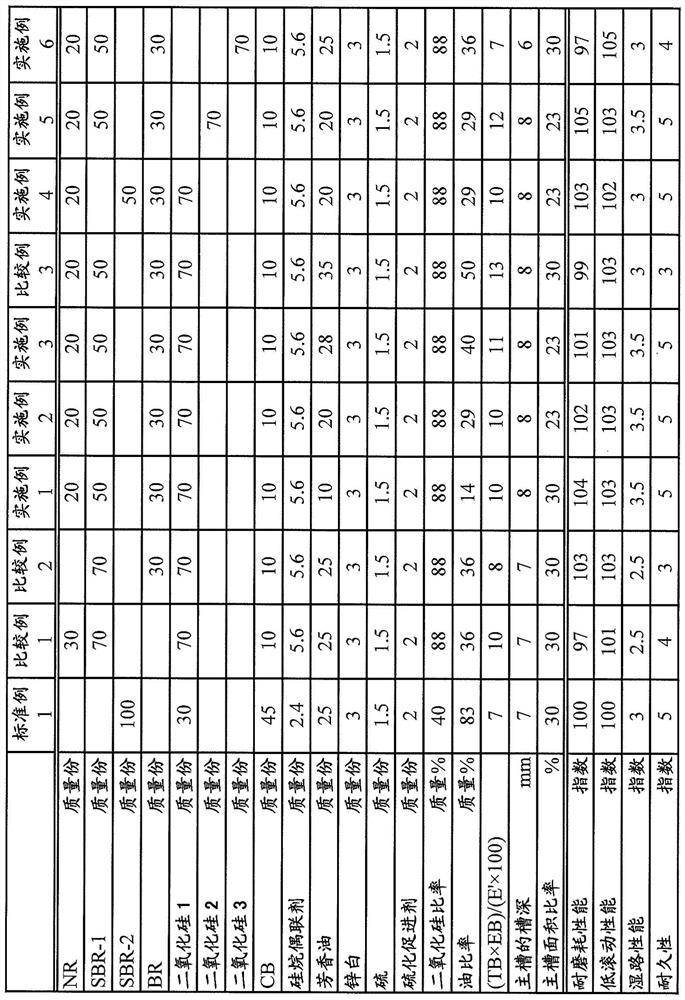

[0040] About 23 kinds of rubber compositions for treads (Standard Example 1, Comparative Examples 1 to 7, Examples 1 to 15) composed of the compounds shown in Tables 1 to 3, the compounding components except the vulcanization accelerator and sulfur were weighed, respectively. The mixture was kneaded for 5 minutes with a 1.7 L closed Banbury mixer, and the master batch was discharged at a temperature of 150° C. and cooled at room temperature. Then, this master batch was supplied to the same 1.7 L closed Banbury mixer, a vulcanization accelerator and sulfur were added, and the mixture was mixed for 2 minutes to prepare a rubber composition for treads.

[0041] In addition, in Tables 1-3, the compounding quantity of SBR1-3 describes the compounding quantity of the substantial rubber component after removing the oil content of an oil-extended product. In addition, the column of aromatic oil includes the total amount of the aromatic oil blended in the rubber composition for treads ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com