Automatic green plant trimming device

An automatic pruning and green planting technology, which is applied to hedge trimming equipment, botanical equipment and methods, cutting tools, etc., can solve the problems of low degree of automation, non-adjustable pruning style, and single working form of the pruning device, so as to reduce dust. , Good pruning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

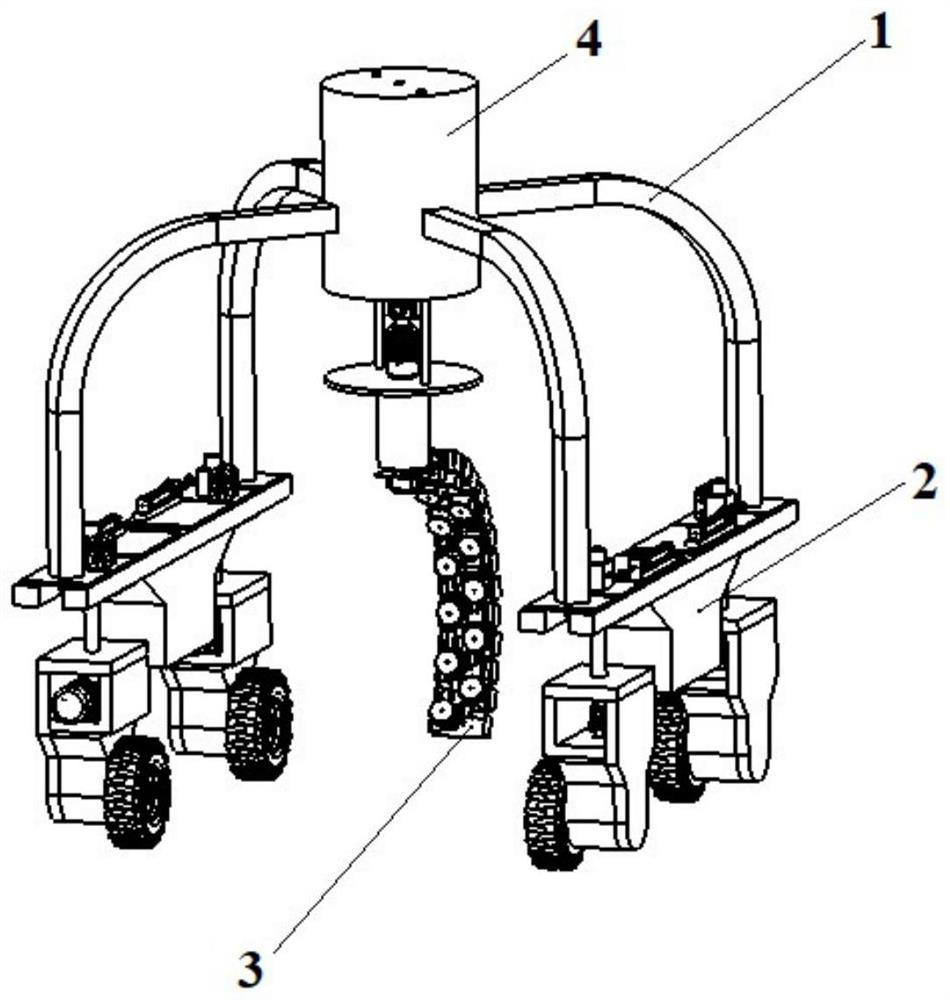

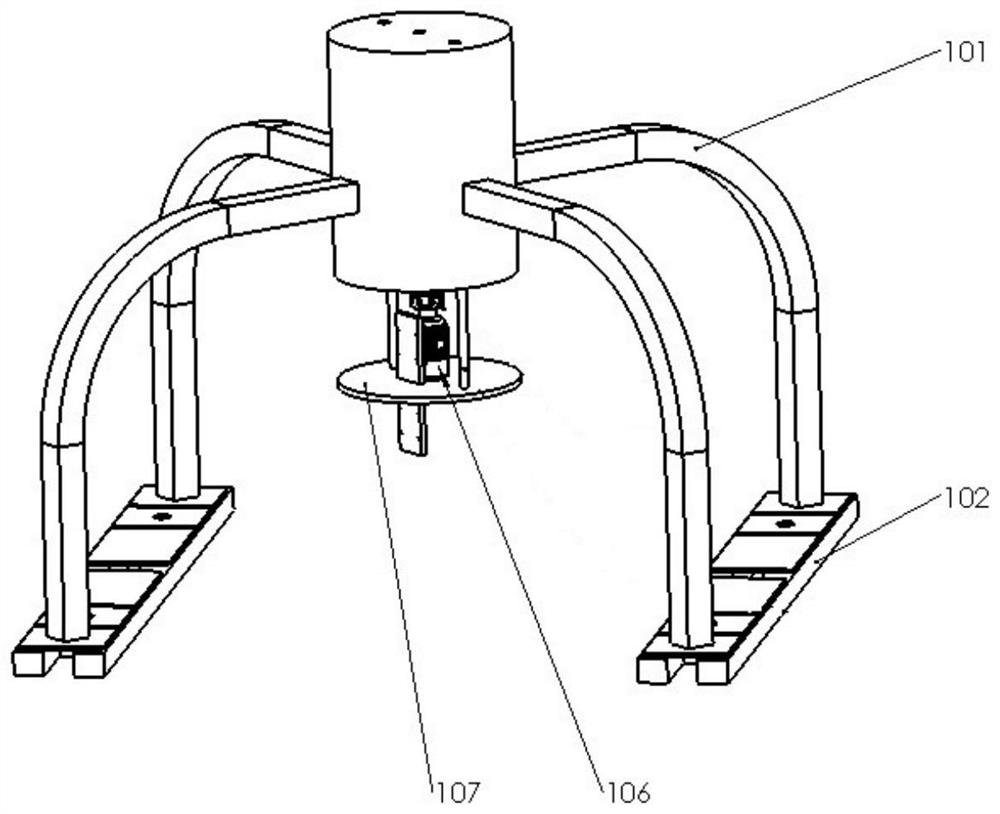

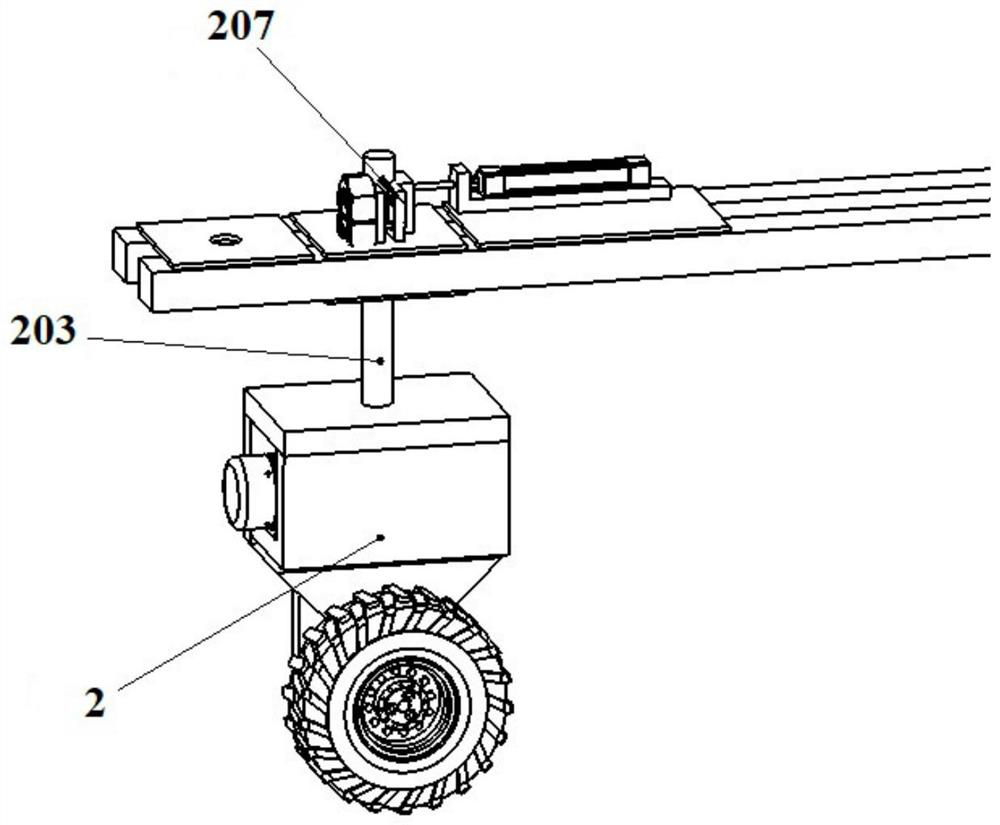

[0027] Such as Figure 1-5 As shown, a kind of automatic pruning device for green plants of the present invention comprises a gantry 1, a central control box fixing shell 4 is arranged in the middle of the gantry 1, and the central control box 5 is arranged in the central control box fixing shell 4, and the electronic equipment in the device is all Connected to the central control box 5, under the control of the central control box 5, the central control box fixed shell 4 symmetrically delays in four directions to form a semi-arch-shaped support leg 101, and the support leg 101 can be stretched up and down, so as to raise or Reduce the overall height of the gantry 1. The bottom of the supporting leg 101 is fixedly connected to the supporting plate 102, and two hydraulic cylinders 204 are arranged above the supporting plate 102 on one side. 207 clamps the rotating rod 203 extending downward, the rotating rod 203 is connected with the connecting seat 208 of the wheel part 2, th...

no. 2 example

[0030] Such as Figure 6 As shown, an automatic green plant pruning device of the present invention includes a flat mobile trolley 6, a mechanical arm 7 and a central control box 5 erected on the flat mobile trolley 6, and the top of the mechanical arm 7 is sequentially suspended three-phase asynchronous deceleration Motor 8, elastic coupling 9, thrust cylindrical roller bearing, pruning assembly 3; one side of pruning assembly 3 is also provided with a water pipe 11, one end of the water pipe 11 is closed, and the other end is connected with the pump water tank 10 arranged on the flat mobile trolley 6 Connected, the water pipe 11 is provided with several mist nozzles, the mist nozzles are directed towards the trimmed green plants, the water pumping tank 10 pumps water into the water pipe 11 through its own water pump, and sprays out in the form of mist from the mist nozzles, which can increase the greenness of the green plants on the one hand. Wet, on the other hand, reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com