Medical puncture needle

A puncture needle and medical technology, applied in the medical field, can solve the problems of easy puncture of other tissues and organs, easy to pierce blood vessels, easy occurrence of danger, etc., and achieve the effects of reducing puncture errors, delaying the puncture process, and facilitating puncture positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

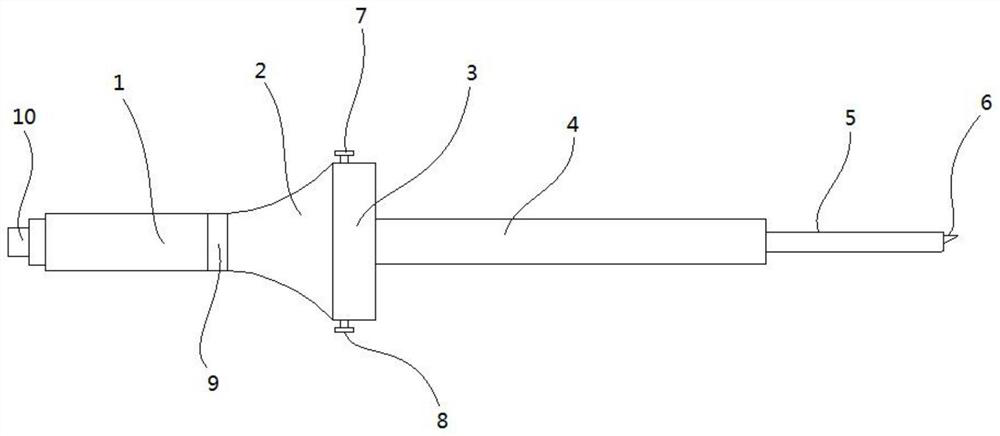

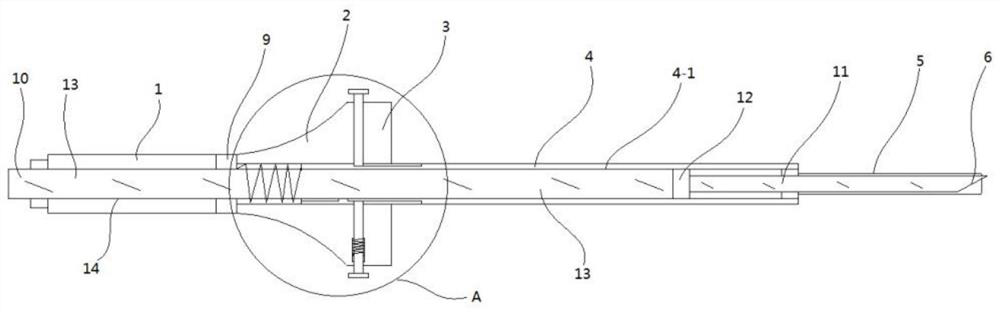

[0031] Such as figure 1 , figure 2 As shown, a medical puncture needle includes a handle 1, a fixed block 9, a connecting portion 2, a limiting portion 3, a first sleeve 4, a second sleeve 5, and a needle head 11. The front end of the needle head 11 is provided with There is a spiked part 6, and the rear end is connected with a hard guide tube 13. The second sleeve 5 is sleeved on the front part of the needle 11 and is slidably connected with the outer wall surface of the needle. The first sleeve 5 4 is fixedly connected to the rear end of the second sleeve 5, the rear end of the needle extends into the first sleeve 4, the inner wall surface of the first sleeve 4 is connected to the hard guide tube 13 The surface of the outer wall is slidingly connected, the front end of the handle 1 is fixedly connected to the rear end of the fixed block 9, or integrally formed, and the front end of the fixed block 9 is fixedly connected to the rear end of the connecting part 2, or integral...

Embodiment 2

[0035] On the basis of Embodiment 1, this embodiment has made further improvements, specifically:

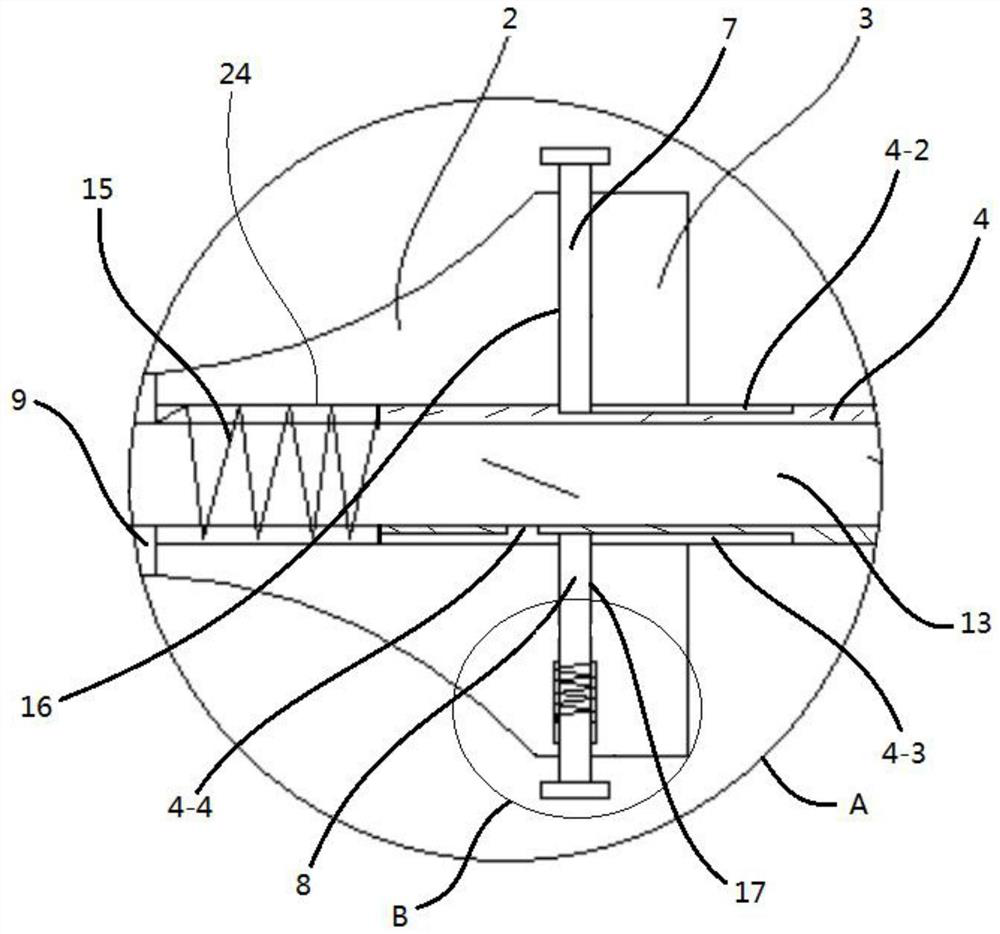

[0036] Such as image 3 As shown, the limiting part includes a first chute 4-2 located on the outer wall surface of the first sleeve 4 and arranged along the axial direction of the first sleeve 4, the rear of the first chute 4-2 The end extends into the sliding hole 24, and the first positioning hole 16 is provided on the position-limiting part 3 along the direction perpendicular to the first sleeve 4, and the first positioning rod 7 is arranged in the first positioning hole. The lower end of the first positioning rod 7 is inserted into the first chute 4-2, and is slidably connected with the first chute 4-2.

Embodiment 3

[0038] On the basis of Embodiment 2, this embodiment has made further improvements, specifically:

[0039] The front end of the second sleeve 5 completely covers the spiked portion 6. When not piercing, the lower end of the first positioning rod 7 is located in the middle of the first chute 4-2, and can be positioned along the side of the first chute 4-2. The bottom of the groove slides back and forth (not drawn among the figure, the positional relationship between the bottom of the second positioning rod 8 and the second chute 4-3 in shape, only there is no limit hole in the first chute 4-2).

[0040] In this embodiment, when puncturing, hold the handle 1, first put the two side edges of the second cannula 5 against the two sides of the blood vessel, and position the spiked part 6 contained in the second cannula to align with the midline of the blood vessel , and then gently push the handle 1 to perform the puncture action, the skin squeezes the second cannula 5, exposing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com