Hemodialysis concentrate preparation device

A configuration device and hemodialysis technology, applied in dialysis systems, transportation and packaging, mixer accessories, etc., can solve problems affecting production efficiency, small mixing area, easy deformation of mixing blades, etc., and achieve high automation integration and high mixing efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

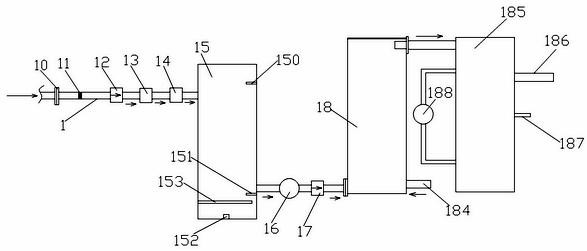

[0018] see Figure 1 to Figure 4 As shown, a hemodialysis concentrate dispensing device includes a water inlet pipe 1, and the water inlet pipe 1 is sequentially connected with a flange 10, a filter screen 11, a first solenoid valve 12, a pressure gauge 13, a flow meter 14, a water storage tank 15, Water pump motor 16, second solenoid valve 17 and mixing tank 18;

[0019] The upper and lower ends of the water storage tank 15 are respectively provided with a high liquid level sensor 150 and a low liquid level sensor 151, and the bottom of the water storage tank 15 is provided with a temperature sensor 152, and the water storage tank 15 is provided with an electric heater 153, and the electric heater 153 can control the water storage tank. 15 internal water for heating;

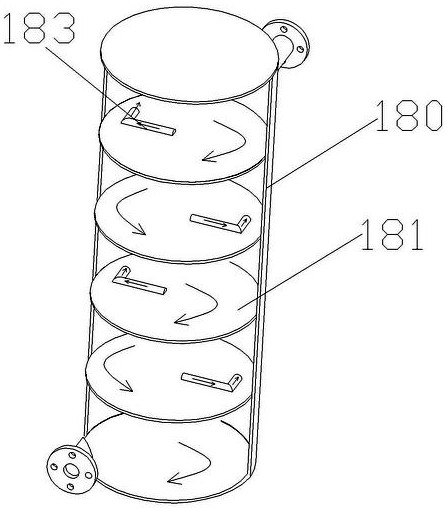

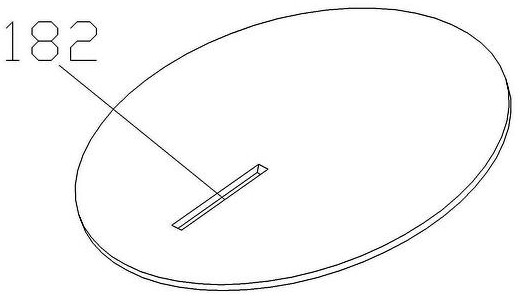

[0020] The mixing tank 18 includes a tank body 180, the inner axial direction of the tank body 180 is divided into a plurality of mixing chambers by a partition plate 181, and a water outlet groove 182 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com