Tissue mashing homogenizer with function of preventing tissue deterioration

A technology of tissue smashing and homogenizing machines, which is applied in household utensils, cleaning methods and utensils, and cleaning hollow objects. It can solve the problems of low power consumption, unusability, and elevated tissue temperature, so as to reduce the probability of deterioration and improve Crushing effect, the effect of improving energy saving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

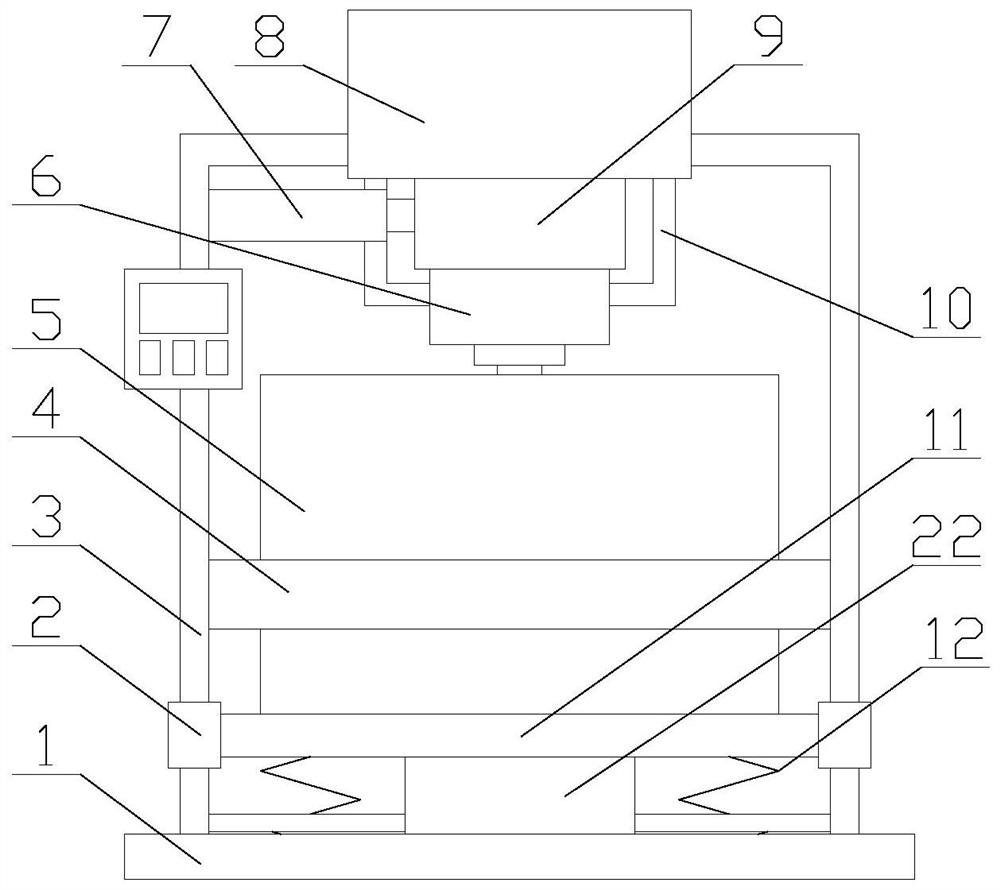

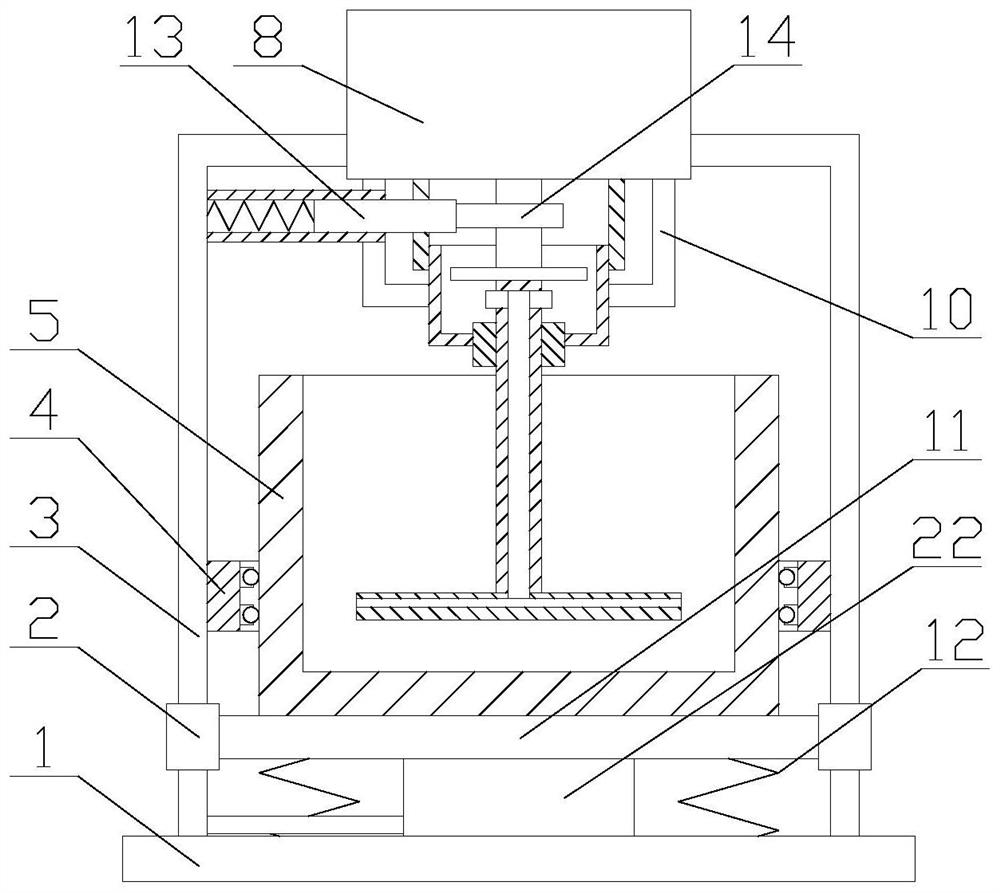

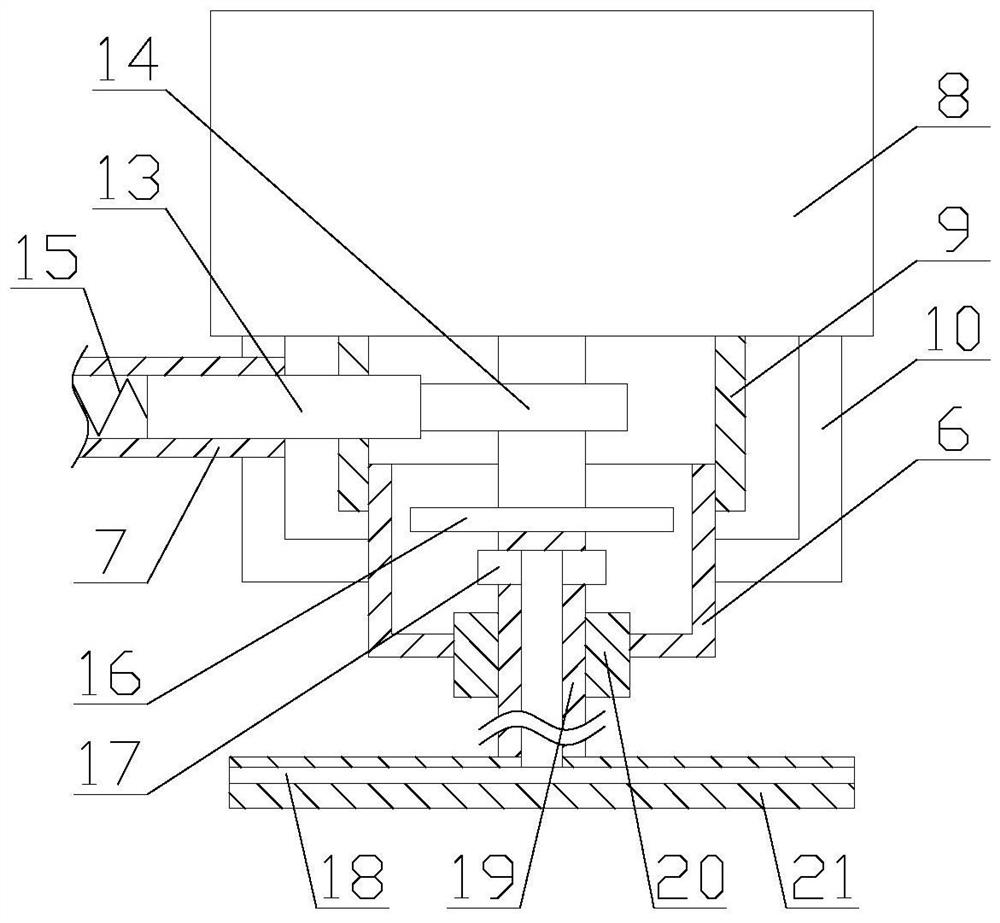

[0024] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0025] Such as Figure 1-2 As shown, a tissue mashing and homogenizing machine with a function of preventing tissue deterioration includes a crushing tank 5, a power device 8, a blade 21 and a drive tube 19, the shape of the crushing tank 5 is cylindrical, the crushing tank The top end of 5 is in a sealed state, the drive tube 19 is arranged coaxially with the crushing tank 5, the blade 21 is arranged inside the crushing tank 5, and the power device 8 is connected to the blade 21 through the drive tube 19 for transmission, and includes heat dissipation. Mechanism and a shaking mechanism, the heat dissipation mechanism is arranged on the drive tube 19, and the shaking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com