Production method and device for galvanized steel plate

A technology of galvanized steel sheet and production method, which is applied in hot-dip plating process, machine tool designed for grinding the rotating surface of workpiece, coating, etc. to guarantee and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

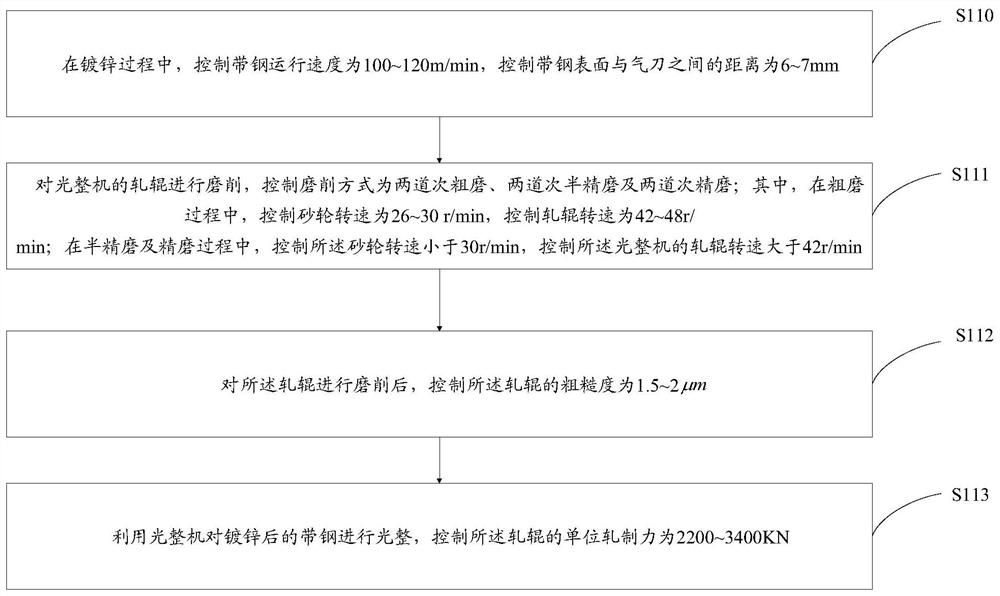

[0030] The present embodiment provides a kind of production method of galvanized steel sheet, as figure 1 As shown, the methods include:

[0031] S110, during the galvanizing process, control the running speed of the strip to 100-120m / min, and control the distance between the surface of the strip and the air knife to 6-7mm;

[0032] Generally, the steel strip can be used as an automobile plate after galvanizing and finishing. During the galvanizing process, an air knife is used to blow away the excess zinc liquid on the surface of the strip steel. In order to avoid the undulation of the zinc layer on the surface of the strip steel, resulting The surface corrugation of the strip is too large. During the galvanizing process, the running speed of the strip is controlled to be 100-120m / min, and the distance between the surface of the strip and the air knife is controlled to be 6-7mm. Among them, the strip thickness is 0.65-0.7mm.

[0033] S111, grinding the roll of the skin pass...

Embodiment 2

[0047] This embodiment provides a production device for galvanized steel sheets, such as figure 2 As shown, the device includes: a first control unit 21, a second control unit 22, a third control unit 23 and a fourth control unit 24; wherein,

[0048] The first control unit 21 is used to control the running speed of the strip steel to be 100-120m / min during the galvanizing process, and to control the distance between the surface of the strip steel and the air knife to be 6-7mm;

[0049] The second control unit 22 is used for grinding the rolls of the skin pass mill, and the control grinding method is two passes of rough grinding, two passes of semi-fine grinding and two passes of fine grinding; wherein, during the rough grinding process , the control grinding wheel speed is 26~30r / min, the control roll speed is 42~48r / min; in the process of semi-finishing and fine grinding, control the speed of the grinding wheel to be less than 30r / min, control the roll speed of the skin pas...

Embodiment 3

[0063] In practical application, when using the method and device provided in Embodiment 1 to produce galvanized automobile outer panels with a thickness of 0.7 mm and a width of 1700 mm, the specific implementation is as follows:

[0064] During the galvanizing process, the running speed of the strip is controlled to be 100m / min, and the distance between the surface of the strip and the air knife is controlled to be 6.5mm.

[0065] After galvanizing, the strip steel after galvanizing needs to be skinned. In order to avoid the roughness of the rolls of the skin pass machine from affecting the waviness of the strip surface, the rolls of the skin pass machine should be ground before skin skinning. cut.

[0066] During the grinding process, the controlled grinding method is coarse grinding, two semi-finishing passes and two fine grindings (that is, two semi-finishing followed by two fine grindings); during the rough grinding process, the grinding wheel speed is controlled It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com