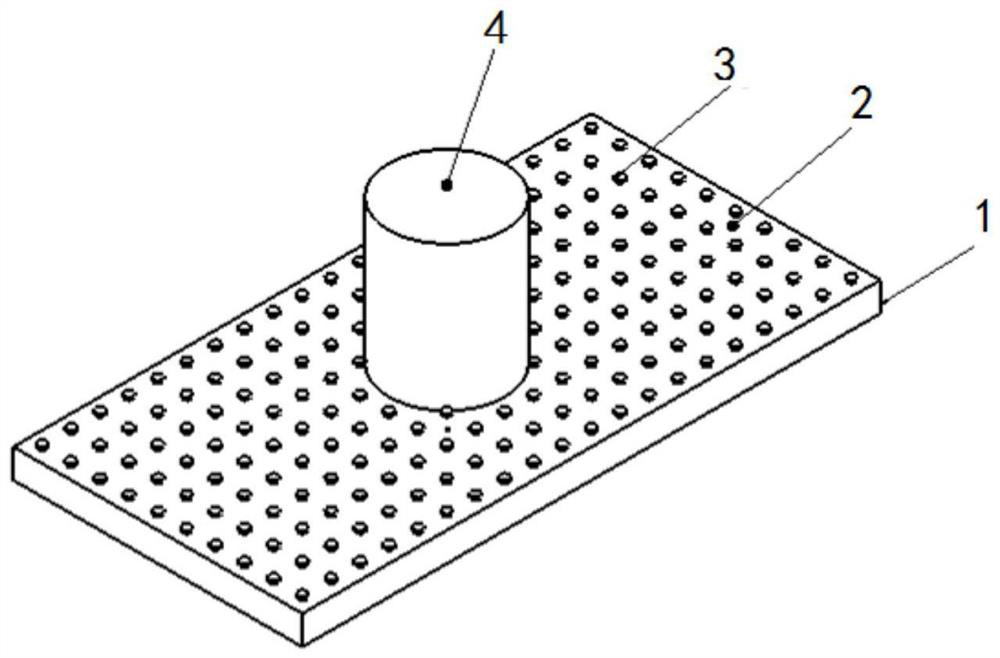

Large-size anti-warping 3D printing flexible bottom plate with easy-to-take part and using method thereof

A 3D printing and anti-warping technology, applied in the field of 3D printing, can solve the problems of large shrinkage and deformation of large-sized parts, and achieve the effects of low cost, avoiding material waste, and easy pick-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] (1) It is planned to print an ABS material with a bottom size of 400mm*400mm;

[0046] (2) Make a rectangular wooden container of 450mm*450mm*5mm (length, width and height) using Auspine board;

[0047] (3) Brush the inner bottom surface of the wooden container with an iron brush to roughen it;

[0048] (4) Clean up the sawdust and dust inside the wooden container 1 with a vacuum cleaner;

[0049] (5) Pour the white latex into the wooden container, and pour the white latex three times. The thickness of each pour is between 1-1.5mm. After each pour, let it stand until the first layer is poured. After the white latex is cured, pour the second layer. After the second layer hardens, pour the third layer. Smooth the surface of the top layer of latex to ensure that the upper surface of the white latex is about 1-1.5mm away from the upper edge of the wooden container. ;

[0050] (6) Evenly lay the dried ABS particles (3mm cylindrical material) on the surface of the flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com