Overturning device and overturning method for fragile slices

A technology of turning device and sheet, applied in the field of automation, can solve the problems of easy deformation, cracking, excessive deformation of the sheet, etc., and achieve the effect of avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

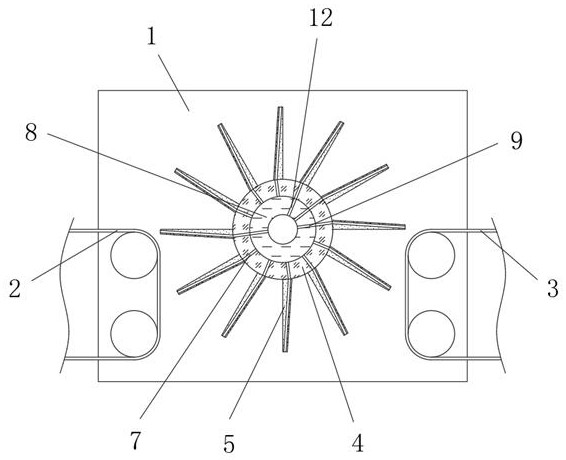

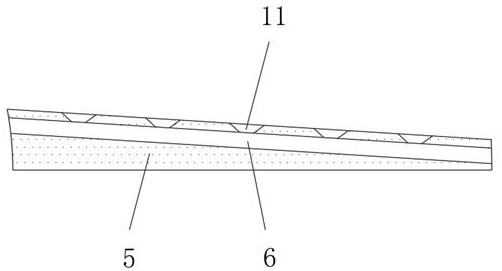

[0024] refer to Figure 1-2 , a turning device for fragile sheets, including two fixed frames 1, the two sides between the two fixed frames 1 are respectively provided with a feed conveyor belt 2 and a discharge conveyor belt 3, and the two fixed frames 1 The intermediate position between the feed conveyor belt 2 and the discharge conveyor belt 3 is rotatably connected with a rotating roller 4, and one end of the rotating roller 4 is connected with a stepping motor, and the outer wall of the rotating roller 4 is fixed with partitions distributed in a ring array. Part 5, and the partition 5 above the rotating roller 4 moves to the side close to the discharge conveyor belt 3. One end of the rotating roller 4 is provided with a flow chamber, and one end of the flow chamber is connected to a blower through an air duct. The inner wall of the flow chamber The position corresponding to the partition 5 is provided with air holes 7 equidistantly distributed in the horizontal direction,...

Embodiment 2

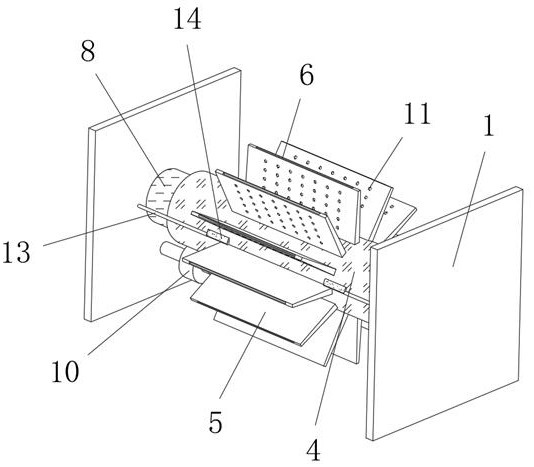

[0028] refer to Figure 1-3, a flipping device for fragile sheets, further on the basis of Embodiment 1, a fixed cylinder 8 is fixed between the two fixed frames 1 corresponding to the flow chamber, and the inner wall of the rotating roller 4 is in contact with the fixed cylinder The outer wall of 8 is slidingly connected, and one end of the fixed cylinder 8 is connected with a blower through the air duct, the stepper motor is fixed on the bottom of the fixed frame 1, the output shaft of the stepper motor is fixed with a drive ring 10, and the outer wall of the drive ring 10 is connected to the rotating roller 4 One end of the outer wall is engaged, and a plurality of through holes 9 are opened on both sides of the fixed cylinder 8 corresponding to the feeding part and the discharging part, and the through holes 9 communicate with the air holes 7. The rotation makes a plurality of air holes 7 communicate with the through holes 9 in turn, and only the air cavity 6 at the positi...

Embodiment 3

[0033] refer to Figure 1-4 , a flipping device for fragile sheets, further on the basis of Embodiment 1 or Embodiment 2, a horizontally placed fixing member 13 is fixed at the position corresponding to the outer wall of one end of the two fixing frames 1 and the feeding member, and the fixed One end of the piece 13 is fixed with a rubber strip 14, the bottom of the rubber strip 14 abuts against the top of the feed piece, and the sheet sent from the feed conveyor belt 2 to the top of the feed piece hits the rubber strip 14 to avoid direct contact with the rotating The impact of the outer wall of the roller 4 causes fragmentation. When the rotating roller 4 is stepping and rotating, the rubber strip 14 bends and moves relative to the feed piece and stays on the top of the next separator 5. The rubber strip 14 is arranged on both sides to reduce friction and Ensure the integrity of continuous operations;

[0034] The bottom of the rubber strip 14 is arranged in an arc-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com