Denitrification deep-bed filter tank denitrification treatment system and method thereof

A nitrification deep bed and treatment system technology, applied in the field of denitrification deep bed filter denitrification treatment system, can solve the problems of increased pool depth and investment cost, poor uniformity of water distribution and gas distribution system, etc., to save investment costs, reverse Good flushing effect, accurate and reasonable dosage of carbon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

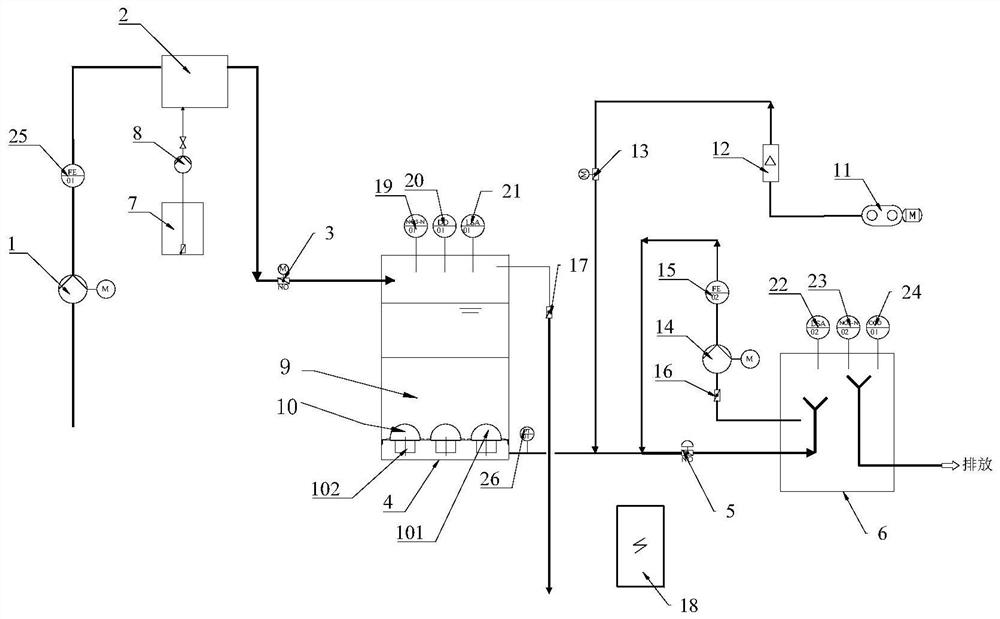

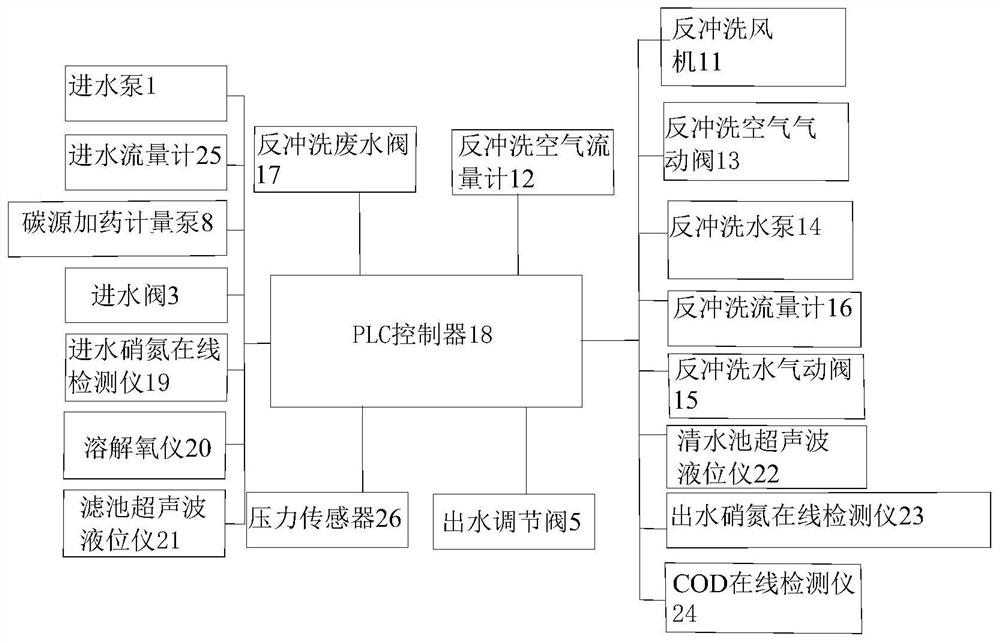

[0040] Such as figure 1 As shown, the present embodiment provides a denitrification deep bed filter denitrification treatment system, including a filter 4, and the filter 4 includes a superelevation zone, a filter water head zone, a filter material zone 9, Air-water distribution system 10 and water collecting channel. The air-water distribution system 10 includes a stainless steel screen 101 at the top and a pipeline 102 at the bottom, and the top of the pipeline 102 is connected to the stainless steel screen 101 . The top of the stainless steel filter screen 101 can directly support the filter material in the filter material area 9, and the pipeline 102 can extend to the water collection channel and communicate with the water collection channel, wherein the stainless steel filter screen 101 has a semicircular arc structure in longitudinal section. Preferably, the pipeline 102 has a columnar structure.

[0041] Preferably, the stainless steel filter screen 101 has a height o...

Embodiment 2

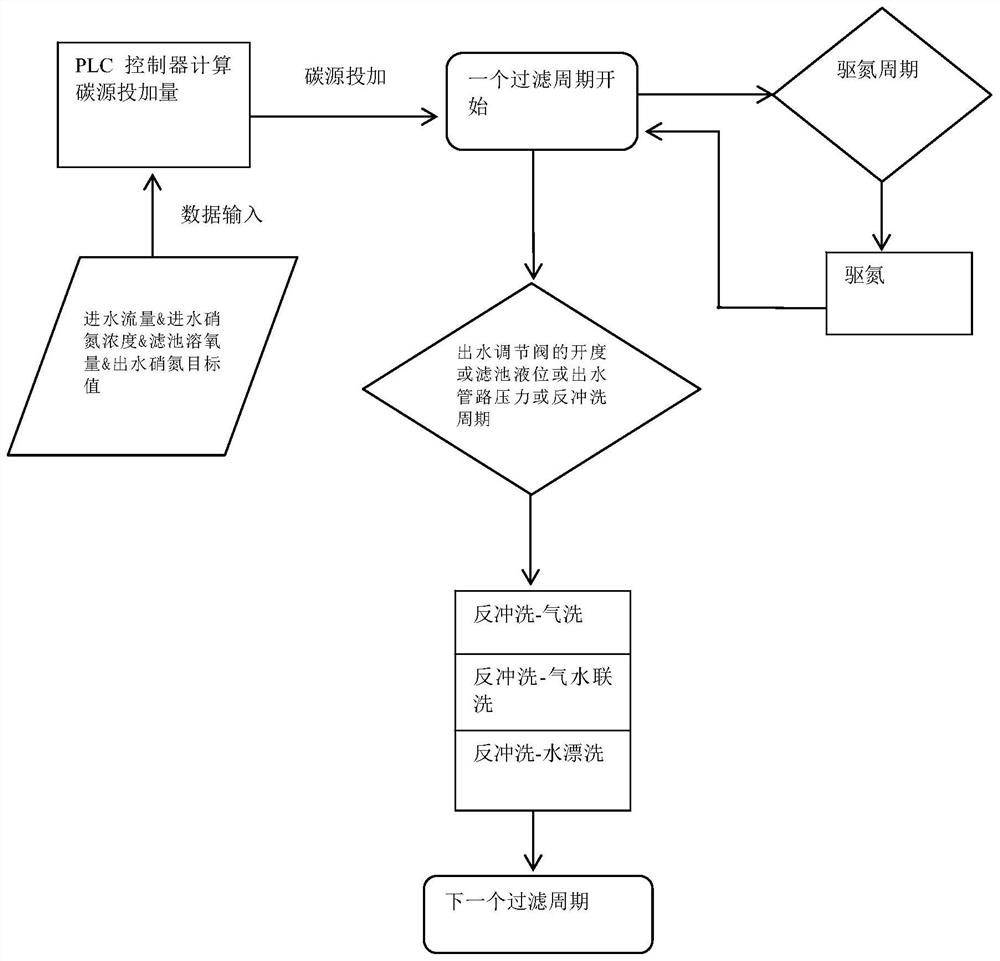

[0060] Such as image 3 As shown, this embodiment provides a denitrification deep-bed filter denitrification treatment method, and the treatment method is operated by the denitrification deep-bed filter denitrification treatment system described in Example 1. The treatment method includes a dosing process, a nitrogen driving process and a backwashing process within a filtration cycle.

[0061] Preferably, the dosing process includes obtaining the carbon source dosage value based on the influent flow rate, the influent nitrate nitrogen concentration, the dissolved oxygen content of the filter and the effluent nitrate nitrogen target value, and adding the obtained carbon source dosage value to the carbon Source mixing pool.

[0062] Preferably, the nitrogen removal process includes starting a nitrogen removal program based on the set nitrogen removal period.

[0063] Preferably, the backwashing process includes starting the backwashing procedure based on the opening of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com