A kind of flame-retardant self-adhesive adhesive for composite gas isolation board and its preparation method

A technology of self-adhesive and isolation boards, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as structural leakage, and achieve the effects of improving flame retardancy, reducing flow, and reducing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

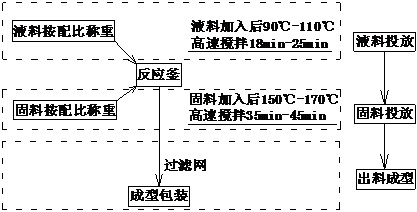

[0065] Preparation of flame retardant self-adhesive for composite gas insulation board:

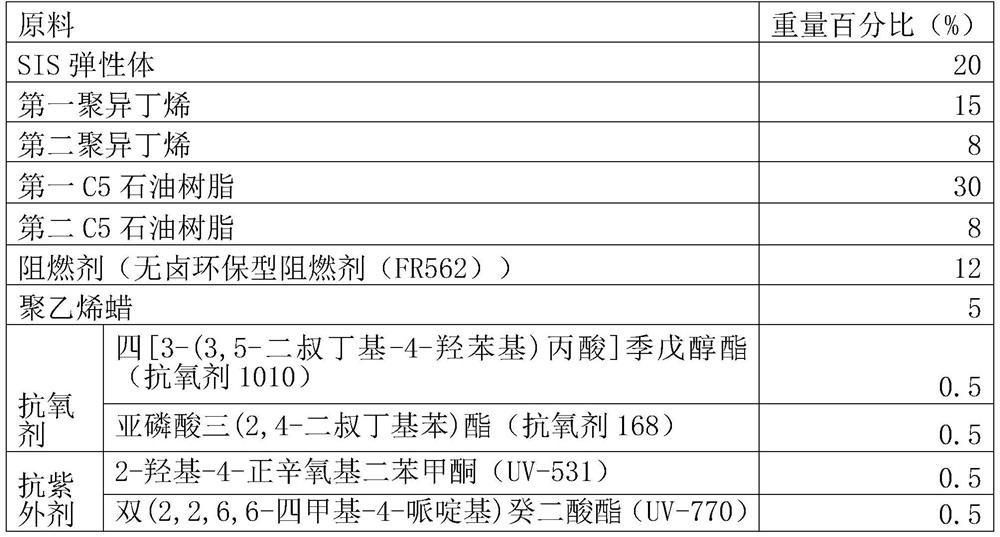

[0066] 1.1 Raw materials, as shown in Table 1 below:

[0067] The raw material that table 1 embodiment 1 adopts

[0068]

[0069] 1.2 Preparation method:

[0070] (1) Liquid material feeding: put the first polyisobutylene, the first C5 petroleum resin and the second C5 petroleum resin into the reaction kettle after weighing according to the proportion, and carry out high-speed stirring for 20min at a temperature of 100°C. The stirring of the high-speed stirring The speed is 8HZ until the mixture is uniform;

[0071] (2) Solid material feeding: put SIS elastomer, the second polyisobutylene, flame retardant, polyethylene wax, antioxidant and anti-ultraviolet agent into the reaction kettle under the condition of high-speed stirring after weighing according to the proportion, the described The stirring speed of high-speed stirring is 8HZ, and the temperature is raised to 160°C at the same...

Embodiment 2

[0074] Preparation of flame retardant self-adhesive for composite gas insulation board:

[0075] 2.1 Raw materials, as shown in Table 2 below:

[0076] The raw material that table 2 embodiment 2 adopts

[0077]

[0078] 2.2 Preparation method:

[0079] (1) Liquid material feeding: put the first polyisobutylene, the first C5 petroleum resin and the second C5 petroleum resin into the reaction kettle after weighing according to the proportion, and carry out high-speed stirring for 25min at a temperature of 90°C. The stirring of the high-speed stirring The speed is 5HZ until the mixture is uniform;

[0080] (2) Solid material feeding: put SIS elastomer, the second polyisobutylene, flame retardant, polyethylene wax, antioxidant and anti-ultraviolet agent into the reaction kettle under the condition of high-speed stirring after weighing according to the proportion, the described The stirring speed of high-speed stirring is 10HZ, and the temperature is raised to 150°C at the sa...

Embodiment 3

[0083] Preparation of flame retardant self-adhesive for composite gas insulation board:

[0084] 3.1 Raw materials, as shown in Table 3 below:

[0085] The raw material that table 3 embodiment 3 adopts

[0086]

[0087] 3.2 Preparation method:

[0088] (1) Liquid material feeding: put the first polyisobutylene, the first C5 petroleum resin and the second C5 petroleum resin into the reaction kettle after weighing according to the proportion, and carry out high-speed stirring for 18 minutes at a temperature of 110 ° C. The stirring of the high-speed stirring The speed is 10HZ until the mixture is uniform;

[0089] (2) Solid material feeding: put SIS elastomer, the second polyisobutylene, flame retardant, polyethylene wax, antioxidant and anti-ultraviolet agent into the reaction kettle under the condition of high-speed stirring after weighing according to the proportion, the described The stirring speed of high-speed stirring is 5HZ, and the temperature is raised to 170°C a...

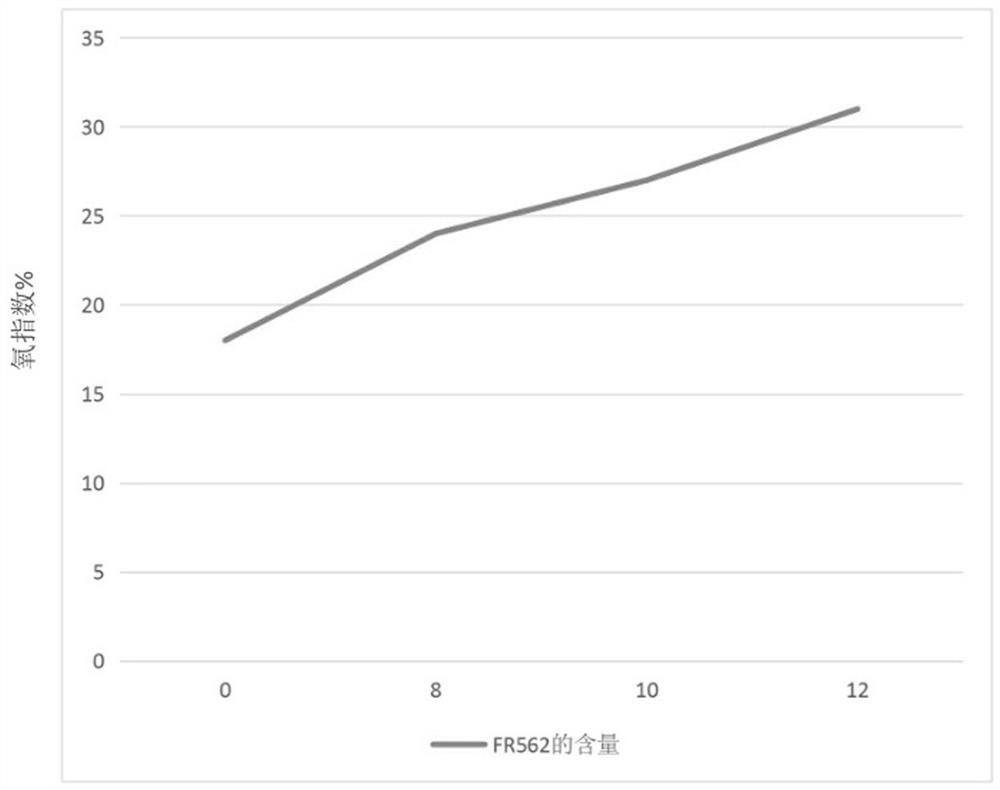

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com