Device and method for detecting quality of slurry in post-tensioned prestressed duct

A detection device and prestressing technology, applied in the direction of material resistance, can solve the problems of affecting the quality of bridges and the lack of a good detection method for the fullness of corrugated concrete, so as to achieve novel detection methods, improve detection quality and detection success rate. , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

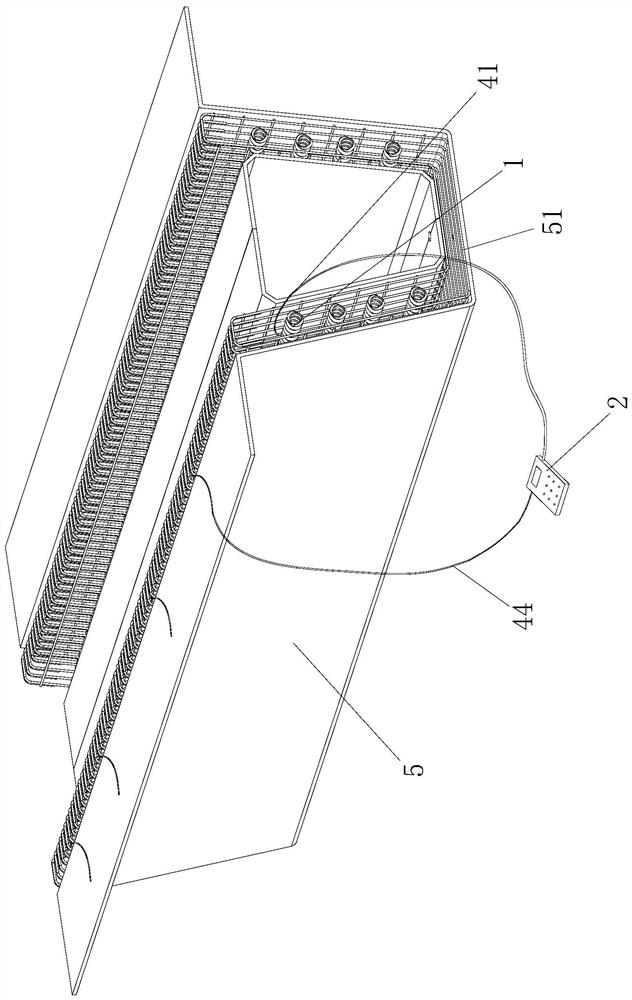

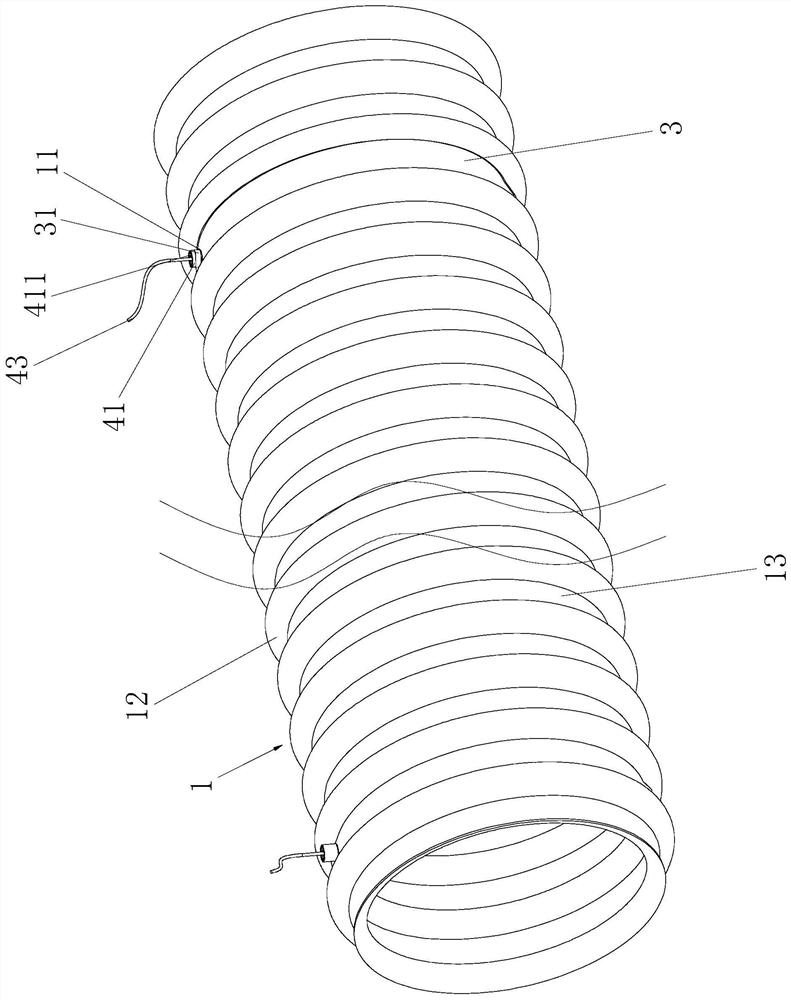

[0036] combine Figure 1 to Figure 6 , a post-tensioning prestressed slurry quality detection device, including a bellows 1 and a resistance detector 2, the end of the bellows 1 is provided with a first connection hole 11, the first connection hole 11 has two Two first connection holes 11 are respectively provided on the left end and the right end of the bellows 1 .

[0037] The bellows 1 at the upper end of each first connection hole 11 is covered with a first metal cable tie 3, the first metal cable tie 3 is connected with a first conductive component 4, and the end of the first conductive component 4 passes through the first metal cable tie 3 and then connected in the first connecting hole 11.

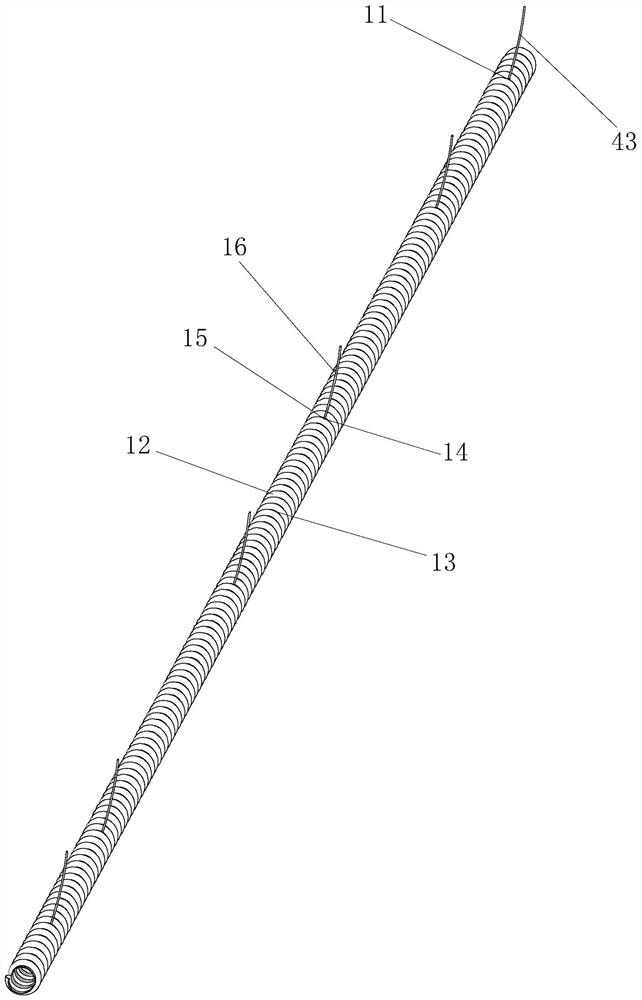

[0038] The first conductive assembly 4 includes a first outer insulating sleeve 41 and a first conductive copper tube 42, the first conductive copper tube 42 is connected with a first conductive wire 43, and the first conductive wire 43 is connected to the resistance detector 2 thr...

Embodiment 2

[0045] A slurry quality detection method, using the above-mentioned slurry quality detection device in the post-tensioning prestressed channel, specifically comprising the following steps:

[0046] Step 1, provide conductive copper pipe, outer insulating sleeve, insulating glue and pliers, use pliers to remove the outer skin of the end of the first conductive wire 43, expose the conductive metal of the first conductive wire 43; Put the conductive metal into the narrow end of the first conductive copper tube 42, then use pliers to pinch the narrow end of the first conductive copper tube 42, so that the narrow end of the first conductive copper tube clamps the first conductive wire conductive metal. The first conductive copper tube 42 is in the shape of a tapered tube, and can better clamp the conductive metal of the first conductive wire after being pinched.

[0047] Step 2, filling the insulating glue into the first outer insulating sleeve 41, and then putting the first condu...

Embodiment 3

[0054] The above slurry quality detection method, through the use of conductive copper tubes, outer insulating sleeves and insulating glue, can better improve the accuracy of conduction and avoid the influence of external concrete mortar on conductive components. During the detection process, the head of the conductive component can be cut off according to the need, and the cross section of the conductive copper tube is exposed after cutting off. Since the conductive copper tube is covered with insulating glue inside and outside during the processing process, the conductive copper tube only passes through the exposed part. The cross section conducts electricity.

[0055] When the corrugated pipe is not filled with concrete mortar, the resistance detected by the resistance detector is infinite due to the contact between the conductive copper pipe and the air; when the conductive copper pipe is in contact with the concrete mortar, the resistance detected by the resistance detecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com