A rotor core structure

A rotor iron core and iron core technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, electromechanical devices, etc., can solve the problem of large magnetic flux leakage coefficient, reduce the magnetic leakage coefficient and avoid irreversible high temperature The effect of loss of magnetic field and reduction of magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

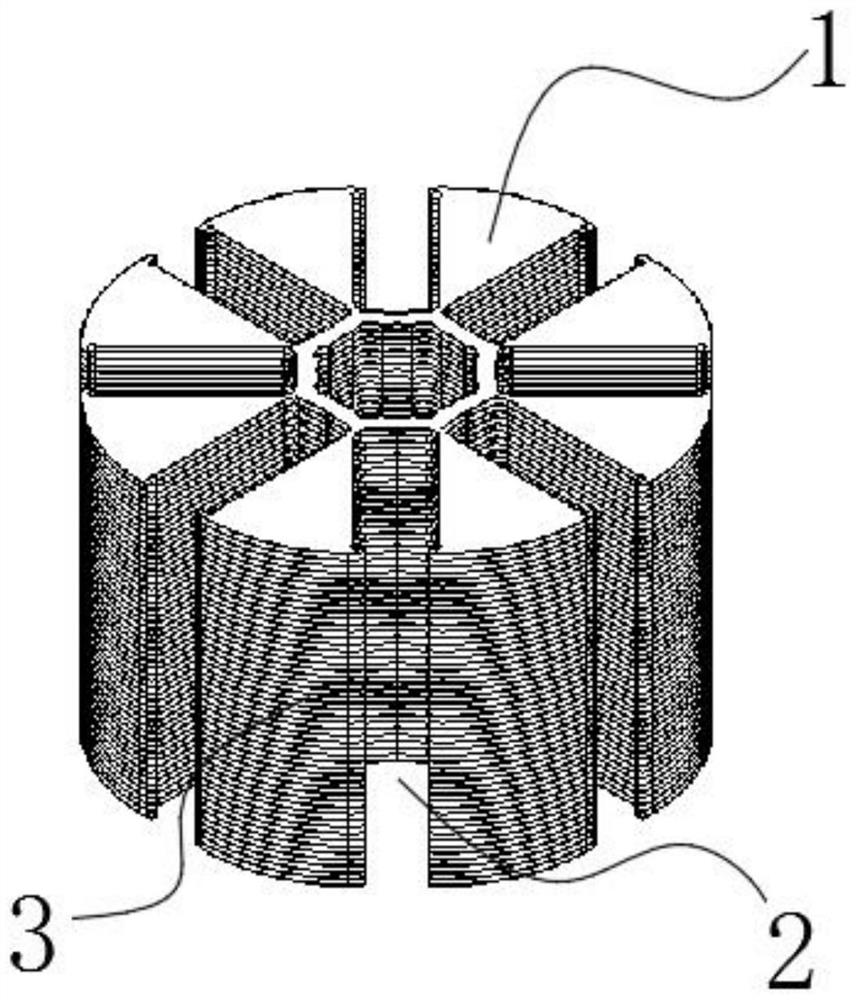

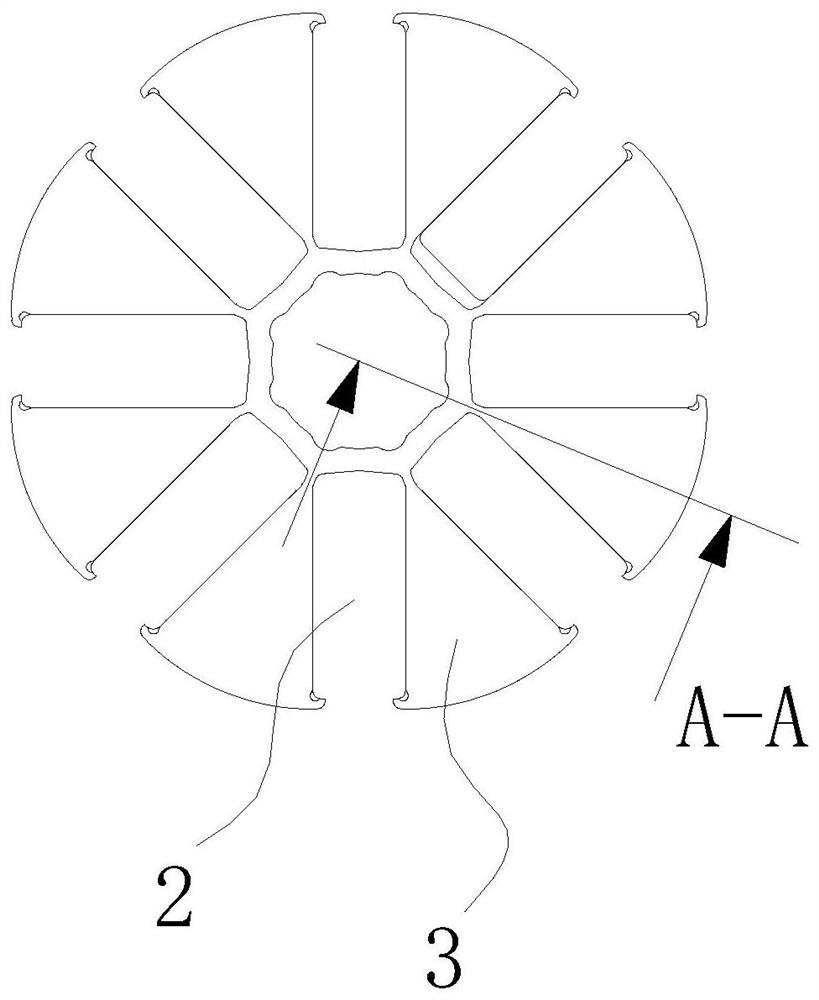

[0024] refer to Figure 1 to Figure 5 , a rotor core structure, including a core body 1 and a magnetic steel slot 2 for installing permanent magnets;

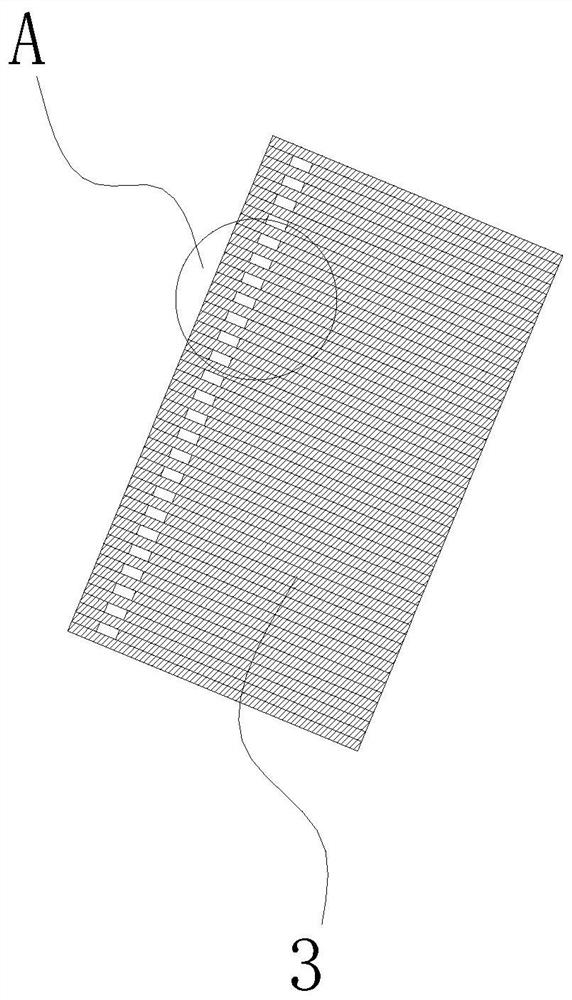

[0025] A magnetic conductor 3 is formed between adjacent magnetic steel slots 2, and a single magnetic conductor 3 is composed of first magnetic permeable sheets 4 and second magnetic permeable sheets 5 with the same size and thickness;

[0026] A magnetic resistance groove 6 is provided on the second magnetic conductive sheet 5, and the magnetic resistance groove 6 is provided to provide a uniform gap inside the magnetic conductive body 3, so as to block the magnetic force lines through the gap and reduce the magnetic flux leakage coefficient;

[0027] Here, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com