Rolled copper foil for flexible printed substrate, flexible copper-clad laminate and flexible printed circuit substrate

A technology of flexible printing and calendering copper foil, applied in the directions of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of reduced bending, cube suppression, etc., to achieve the effect of excellent folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Examples of the present invention will be shown below, but these are examples provided to further fully understand the present invention, and are not intended to limit the present invention.

[0066] [Manufacture of rolled copper foil]

[0067] The copper alloy with the composition described in Table 1 is used as a raw material to cast an ingot, and hot rolled at 800°C or higher until the thickness reaches 10mm. Rolling and finishing to a thickness of 0.009~0.018mm. The oxygen-free copper described in Table 1 is based on JIS-H0500 (C1011).

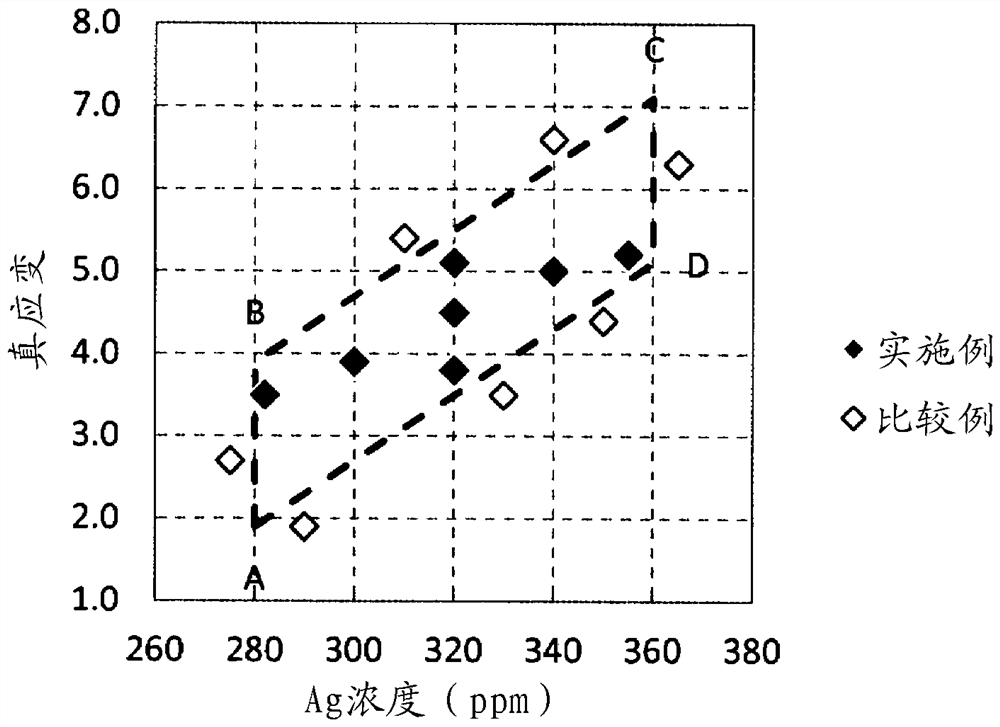

[0068] The calendering degree in the final cold rolling is set to 85~99.9% (1.9~6.6 in terms of true strain η), and the calendering degree (true strain η) in the final cold rolling of the embodiment is equal to the Ag concentration of the sample ( 280~360ppm) range such as image 3 As shown, adjust to the above (0.04 x C Ag -9.3)≤η≤(0.04C Ag -7.3).

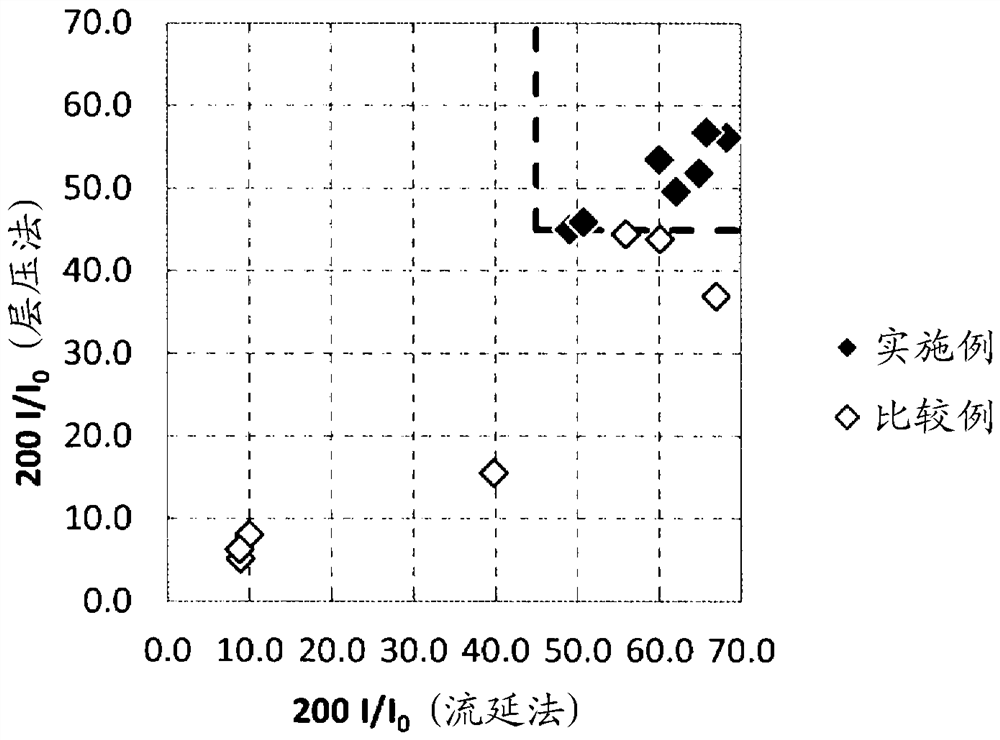

[0069] For each rolled copper foil sample obtained in this way, I / I 0 and ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com