Aluminum alloy floor copper-nickel-chromium electroplating production line and production process thereof

A technology of copper-nickel-chromium and aluminum alloy, which is applied in the electrolysis process, electrolysis components, cleaning methods using tools, etc., can solve the problems of affecting the electroplating quality of the plated parts, the inability to clean the plated parts, and the reduction of the pre-treatment quality of the plated parts, etc., to achieve Ensure the quality of electroplating, good flushing effect, and improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

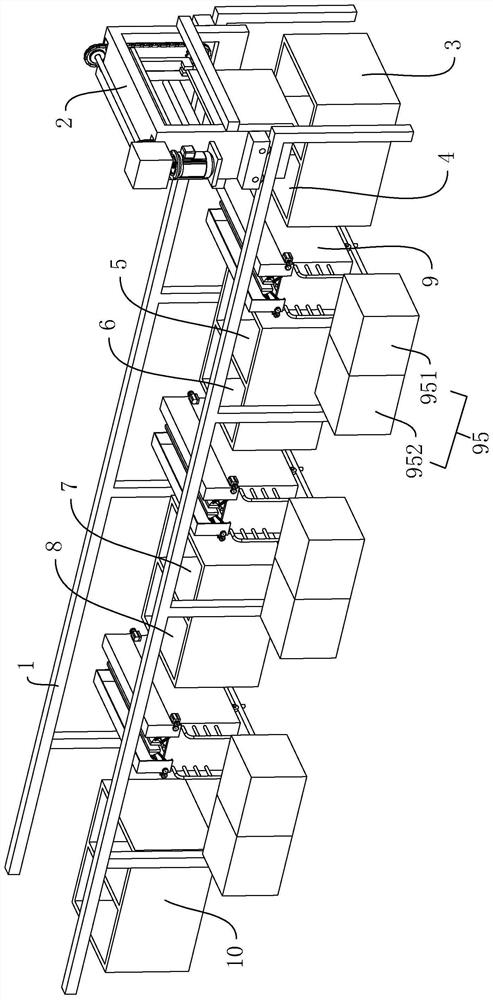

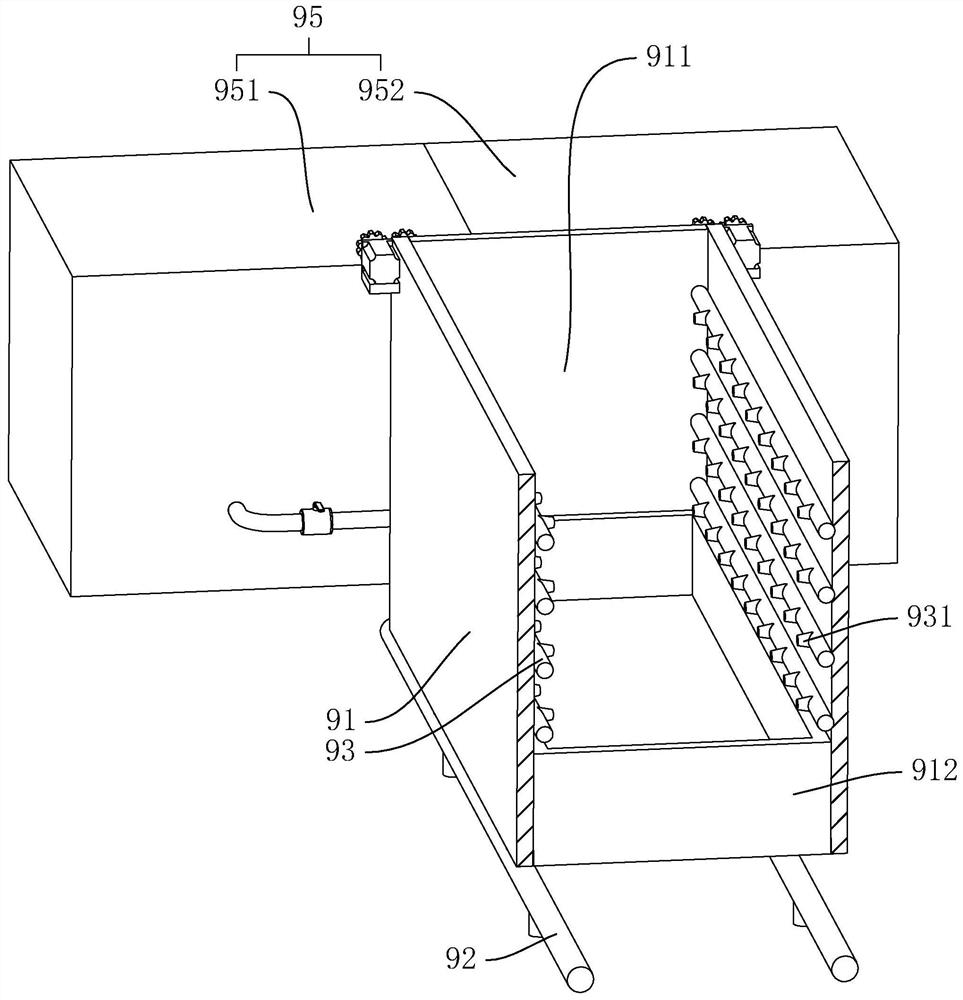

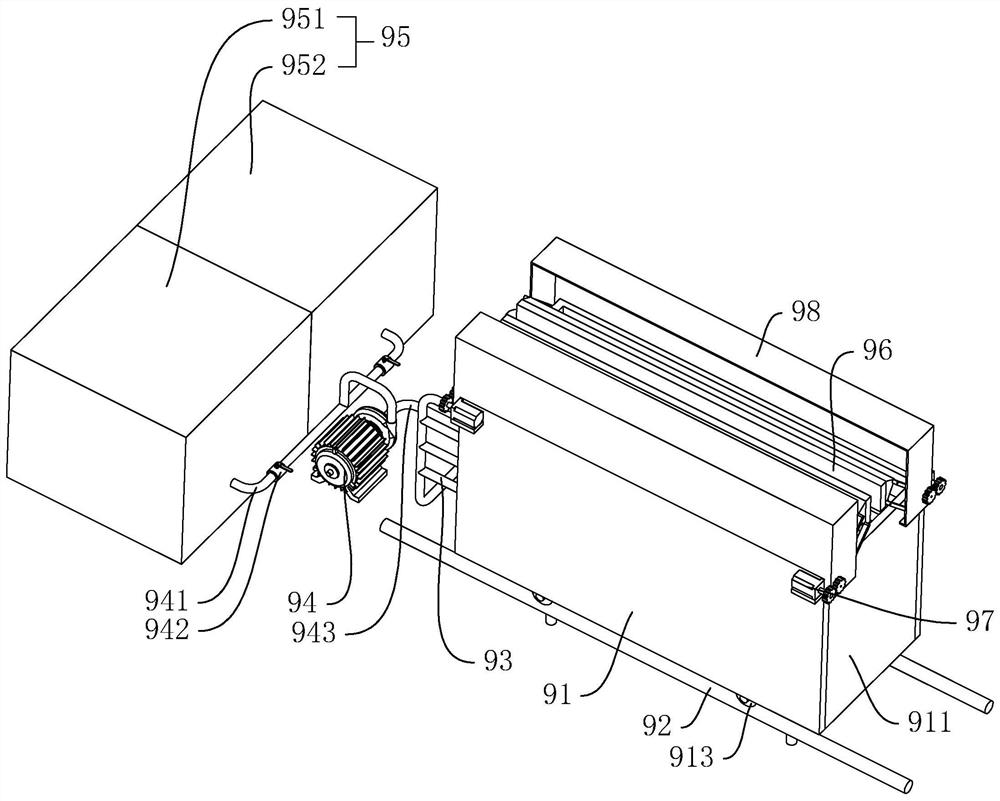

[0056] refer to figure 1 , is an aluminum alloy floor electroplating copper-nickel-chromium production line disclosed by the present invention, including a track 1, a carriage 2 slidingly connected to the track 1, and a pre-treatment area and an electroplating area arranged under the track 1, the pre-treatment area and the electroplating area Set along the length direction of track 1. The aluminum alloy floor can be fixed on the trolley 2, so that the trolley 2 drives the aluminum alloy floor to move along the track 1. The pretreatment area includes an ultrasonic degreasing tank 3, a first cleaning tank 4, ash removal tank 5, a second cleaning tank 6, a zinc precipitation tank 7 and a third cleaning tank 8 arranged in sequence along the moving direction of the plated parts. The first cleaning tank 4 A spray device 9 is provided between the ash removal tank 5 and between the second cleaning tank 6 and the zinc precipitation tank 7 , and a spray device 9 is also provided on the...

Embodiment 2

[0070] A production process for electroplating copper-nickel-chromium on an aluminum alloy floor, comprising the following steps:

[0071] 1) Incoming material inspection, to check whether the quality of the blank meets the requirements of electroplating;

[0072] 2) Warehouse storage;

[0073] 3) The plated parts are moved to the electroplating workshop;

[0074] 4) Hang up, hang the plated parts under the carriage 2;

[0075] 5) Ultrasonic degreasing, place the plated parts in the ultrasonic degreasing tank 3, and the ultrasonic degreasing time is 3-5min;

[0076] 6) Cleaning, washing in the cleaning tank and spraying device 9 respectively, the washing time in the cleaning tank is not less than 2min, and the spraying device 9 uses cold water and hot water to rinse the plated parts in sequence, and the temperature of the hot water is 50°C- 90℃, and the washing time of cold water and hot water is not less than 2min;

[0077] 7) Ash removal, add ash removal agent to the ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com