An Experimental Rolling Mill of "Replacing Wide with Narrow" Thick Plate

A rolling mill and thick plate technology, which is applied in the field of "replacing wide with narrow" thick plate experimental rolling mills, can solve the problems of inability to accurately characterize the rolling process, loss of thick plate characteristics, and high experimental costs, so as to reduce the difficulty and cost of experiments. The effect of improved efficiency and simple structure of the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

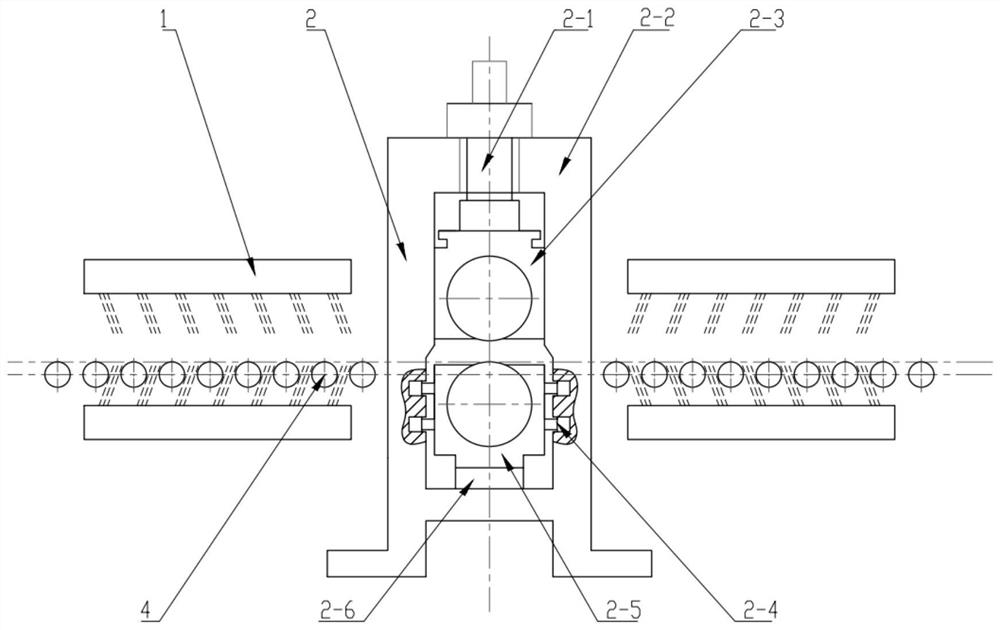

[0031] refer to Figure 1-5 , the present invention provides an experimental rolling mill for "replacing width with narrow" thick plate, comprising an ultra-fast cooling device 1, a roller table 4 and a rolling mill 2, and the ultra-fast cooling device 1 and the roller table 4 are arranged on both sides of the rolling mill 2;

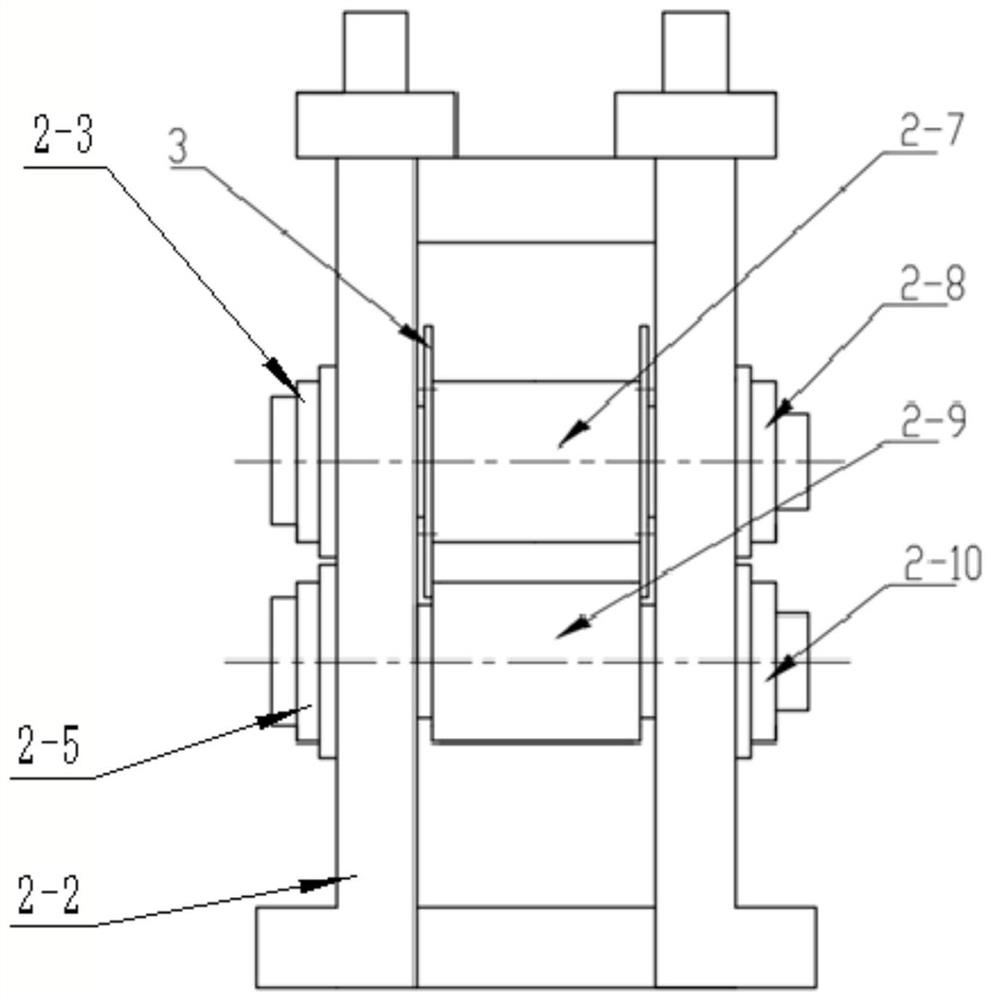

[0032] The rolling mill includes a stand 2-2, two hold-down devices 2-1 and work roll assemblies, the two hold-down devices 2-1 are arranged on the upper part of the stand 2-2, and the work roll assemblies are arranged inside the stand 2-2 ;

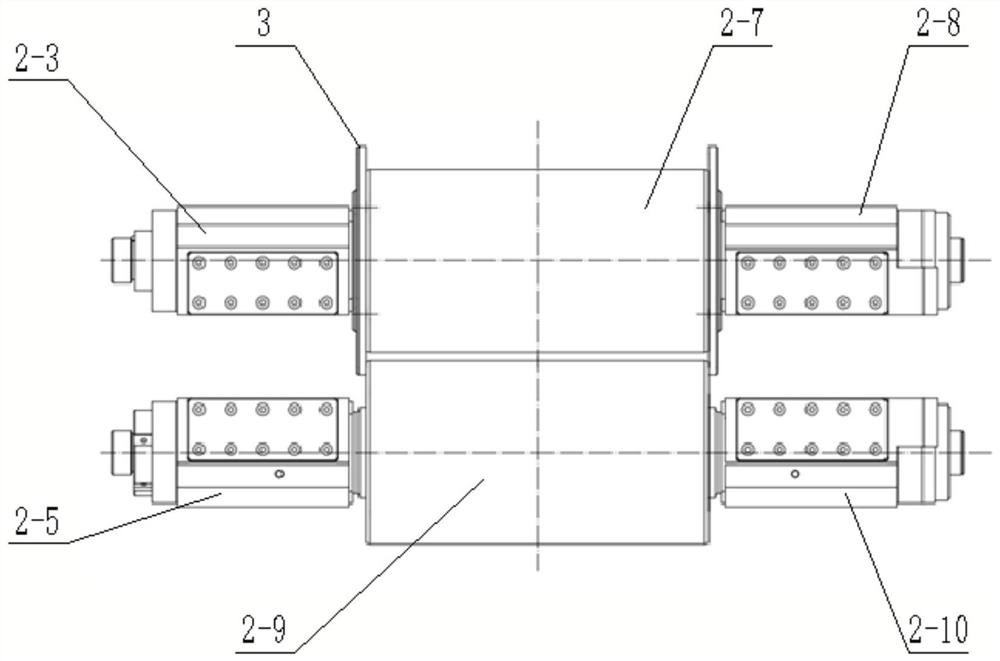

[0033] The work roll assembly includes an upper work roll assembly and a lower work roll assembly. The upper work roll assembly includes upper work rolls 2-7, and the two ends of the upper work rolls 2-7 are respectively provided with a width-limiting plate 3, and the width-limiting plate 3 is sleeved on the upper work roll. Both ends of the roll 2-7 are fixed to the left and right sides of the upper work roll 2-...

Embodiment 2

[0053] A further preferred solution, in this embodiment, the outer sides of the first bearing seat 2-3, the second bearing seat 2-8, the third bearing seat 2-5 and the fourth bearing seat 2-10 are slidingly connected with a sliding sleeve 5, and the sliding sleeve 5 Slidingly connected with the inner wall of the frame 2-2, the left and right sides of the first bearing seat 2-3 and the second bearing seat 2-8 are fixed with T-shaped slide rails 2-15, the third bearing seat 2-5, and the fourth bearing The bottom surface of the seat 2-10 is fixedly connected with a T-shaped slide rail 2-15, and the left and right inner walls of the sliding sleeve 5 and the inner wall of the bottom surface are provided with a T-shaped slide groove 2-16, and the T-shaped slide rail 2-15 is connected with the T-shaped slide groove 2-16. Adaptation, 8 hydraulic cylinders 2-4 are arranged on the left and right sides of the third bearing seat 2-5 and the fourth bearing seat 2-10, and the cylinder bodies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com