Method for detecting feather degradation rate

A degradation rate and feather technology, applied in the field of feather degradation rate determination, can solve the problems of poor parallelism and repeatability of measurement, low measurement efficiency, inaccurate detection results of weight loss method, etc., achieves good parallelism and repeatability, and improves efficiency. , the effect of reducing the difficulty of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of method of measuring feather degradation rate, and this method comprises the steps:

[0028] 1) Mark 30 400-mesh nylon bags (6cm*5cm) with a pencil and dry them at 105°C to constant weight. Weigh each nylon bag and record it as M1;

[0029] 2) Wash and dry the feathers, and after crushing, pass through a 30-mesh sieve and then a 40-mesh sieve to obtain feather powder (about 500 μm);

[0030] 3) Weigh 2g of feather powder, place it in the nylon bag of step 1), seal it and dry it at 105°C to constant weight, weigh it separately, and record it as M2;

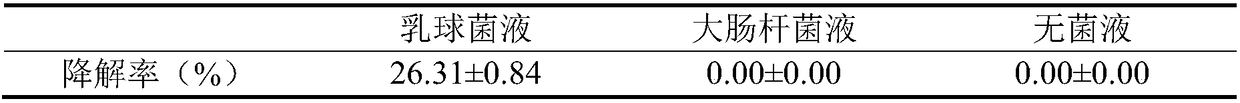

[0031] 4) After the nylon bags are sterilized, at first, get 10 nylon bags and completely immerse in 10 parts of MRS medium, then inoculate feather-degrading bacteria (equivalent to 10 parallel treatments) in 10 parts of MRS medium; secondly, Take 10 nylon bags and submerge them completely in 10 parts of liquid LB medium, then inoculate Escherichia coli (equivalent to 10 parallel tre...

Embodiment 2

[0040] The present embodiment provides a kind of method of measuring feather degradation rate, and this method comprises the steps:

[0041] 1) Mark a 400-mesh nylon bag (6cm*5cm) with a pencil and dry it at 105°C to a constant weight. Weigh each nylon bag and record it as M1;

[0042] 2) Wash and dry the feathers, and after crushing, pass through a 30-mesh sieve and then a 40-mesh sieve to obtain feather powder (about 500 μm);

[0043] 3) Weigh 2g of feather powder, place it in the nylon bag of step 1), seal it and dry it at 105°C until constant weight, weigh it, and record it as M2;

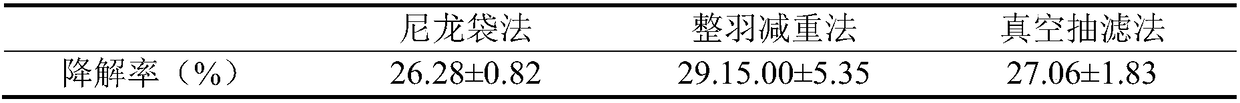

[0044]4) After the nylon bag is sterilized, place the nylon bag in the liquid MRS medium, and inoculate the lactococcus isolated and screened by our laboratory, so that the medium is completely submerged in the nylon bag, and ferment under the optimum growth conditions of microorganisms. After completion, remove the nylon bag and place it in a container, then add 500mL of distilled water to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com