Method for accurately and efficiently testing content of platinum and palladium in ore

A method of determination, platinum and palladium technology, applied in the direction of measuring devices, test sample preparation, sampling, etc., can solve problems such as environmental pollution, lead vapor generation, and complicated experimental procedures, so as to reduce the difficulty of experiments, save power costs, and simplify The effect of the experimental procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Include the following steps:

[0044] (1) Ingredients: Accurately weigh 5g of sample m 0 , put into an assay gold crucible containing 10g sodium carbonate, 10g borax, and 80g lead oxide, add an appropriate amount of potassium nitrate or flour according to its reducing power, then add an appropriate amount of glass powder, stir evenly and cover with 8mm covering agent;

[0045] (2) Melting: Put the crucible in a melting electric furnace with a furnace temperature of 900°C, close the furnace door, heat up to 930°C for 25 minutes, keep it warm for 14 minutes, and then heat up to 1150°C for 30 minutes before coming out of the furnace, and rotate the tongs smoothly for several times and lightly tap twice on the iron plate to sink the lead beads attached to the wall of the clamp, and then carefully pour all the molten material into the preheated cast iron mold. After cooling, put the lead buckle and The slag is separated, and the lead buckle is hammered into flat pieces;

...

Embodiment 2

[0053] Include the following steps:

[0054] (1) Ingredients: Accurately weigh 12g of sample m 0 , put into an assay gold crucible containing 25g of sodium carbonate, 11g of borax, and 100g of lead oxide, add an appropriate amount of potassium nitrate or flour according to its reducing power, then add an appropriate amount of glass powder, and cover with a 9mm covering agent after stirring evenly;

[0055] (2) Melting: Put the crucible in a melting electric furnace with a furnace temperature of 900°C, close the furnace door, heat up to 930°C for 25 minutes, keep it warm for 15 minutes, and then heat up to 1150°C for 30 minutes before coming out of the furnace, and rotate the tongs smoothly for several times and lightly tap the iron plate 3 times to sink the lead beads attached to the wall of the tongs, and then carefully pour all the molten material into the preheated cast iron mold. After cooling, put the lead buckle with the The slag is separated, and the lead buckle is ham...

Embodiment 3

[0063] Include the following steps:

[0064] (1)配料:准确称取20g试料m 0 ,放入盛有40g碳酸钠、12g硼砂、120g氧化铅的试金坩埚中,根据其还原力加入适量硝酸钾或面粉,再加入适量玻璃粉,搅拌均匀后覆盖10mm覆盖剂;

[0065] (2)熔融:将坩埚置于炉温为900℃的熔融电炉内,关闭炉门,25min升温至930℃,保温16min,再经30min升温至1150℃后出炉,将钳祸平稳地旋动数次,并在铁板上轻轻敲击3下,使附着在钳祸壁上的铅珠下沉,然后将熔融物小心地全部倒入预热的铸铁模中,冷却后,把铅扣与熔渣分离,将铅扣锤成扁片;

[0066] (3)使用碾片机将扁片状的铅扣进一步碾成1mm厚的薄片,用剪刀剪碎成铅屑,置于400mL洗净的烧杯中;

[0067] (4)向烧杯中加入50mL硝酸溶液溶解铅屑,待铅屑完全溶解后向烧杯中加入40mL浓盐酸,使溶液成王水体系,溶解没溶于硝酸的铂钯,此时有大量氯化铅沉淀产生,加热煮沸溶液5分钟后,静置冷却;

[0068] (5)使用单层定量滤纸将所得溶液过滤于200mL容量瓶中,洗涤烧杯及滤渣数次后弃去滤渣,加水定容滤液至刻线;

[0069] (6)工作曲线绘制:移取0.00、1.00、5.00、10.00mL铂钯混标基准溶液,浓度100ug / mL,分别置于一组100mL容量瓶中,加入10mL王水,用蒸馏水稀释至刻度,混匀,以铂钯浓度为横坐标,强度为纵坐标,绘制工作曲线;

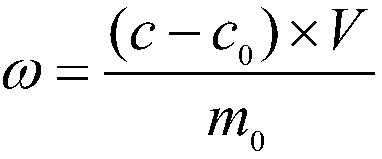

[0070] (7)使用ICP-AES对试样进行测定,自工作曲线上得到相应的铂钯浓度,计算得铂钯含量;

[0071] (8)随同试样做空白实验。

[0072] 上述各实施例中:

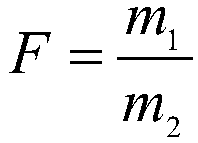

[0073] 本发明所述步骤(1)中,样品还原力计算方法如下:称取5g试料m 2 ,10g碳酸钠、60g氧化铅、10g玻璃粉,搅拌均匀后经熔融得到铅扣m 1 ;

[0074]

[0075] 式中:F-试样的还原力;

[0076] m 1 -铅扣质量,单位是g;

[0077] m 2 -试料质量,单位是g;

[0078] 硝酸钾或面粉的加入量:

[0079] 当m 0 ×F>30时,

[0080] 当m 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com