Plate fixing device with double motors for welding

A fixed device and dual-motor technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as dangers caused by operators, and achieve the effects of improving safety, ensuring physical health, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

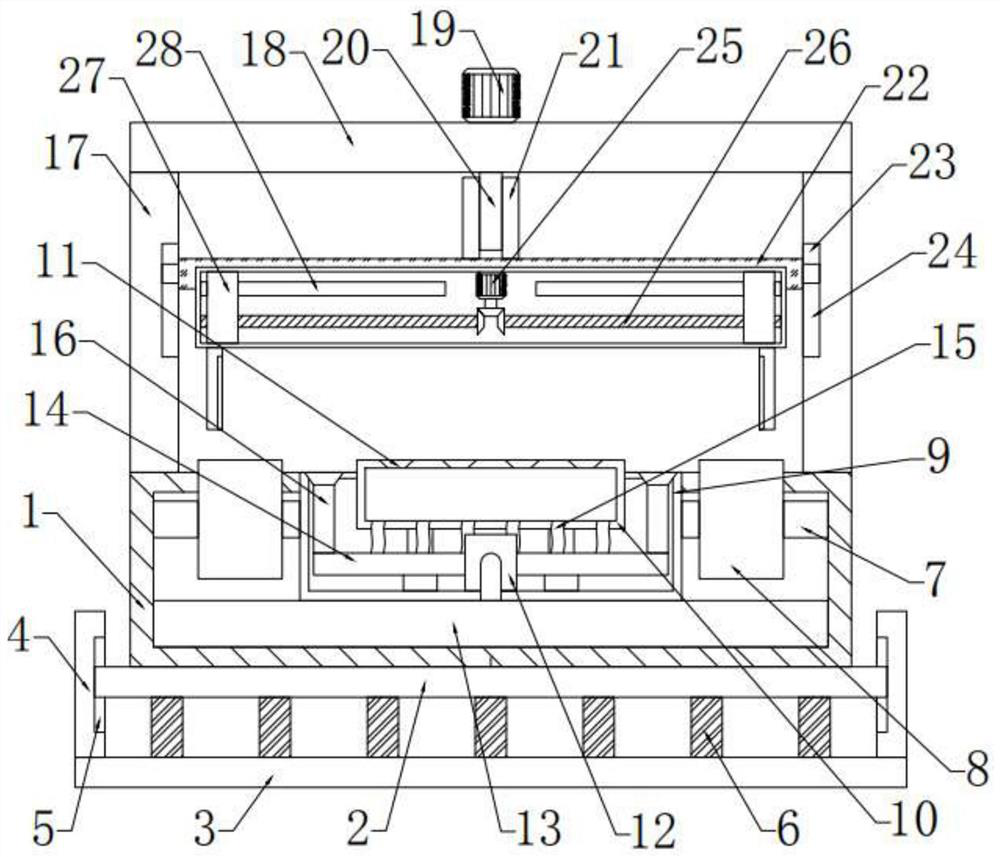

[0024] see Figure 1-3 , in an embodiment of the present invention, a welding plate fixing device with dual motors includes a workbench 1, a fixed frame 9 is fixedly connected to the inner side of the workbench 1, and an adsorption mechanism is arranged on the inner side of the fixed frame 9, The upper side of the adsorption mechanism is provided with a clamping mechanism for fixing the plate, the left and right sides of the fixing frame 9 are provided with conveying mechanisms, and the bottom of the workbench 1 is provided with a shock absorbing mechanism.

Embodiment 2

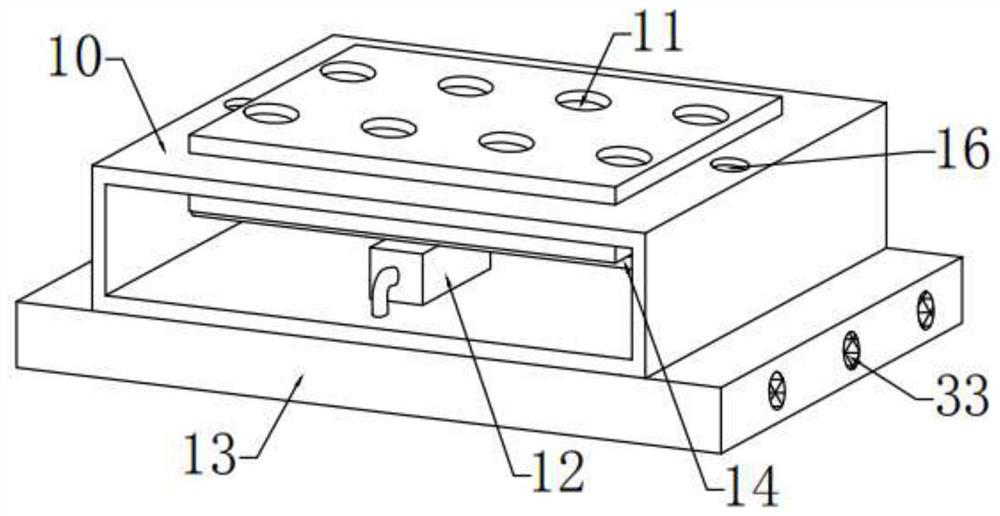

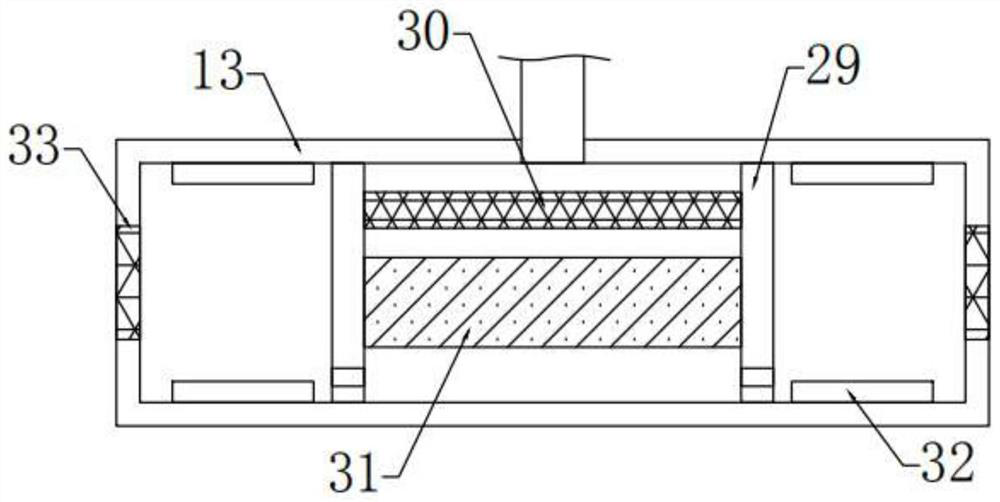

[0026] In this embodiment, the adsorption mechanism includes an adsorption box 10, which is slidingly connected and arranged inside the fixed frame 9, and a telescopic rod is fixedly connected between the bottom end of the adsorption box 10 and the fixed frame 9. The lower side of the adsorption box 10 is provided with an air pump 12 fixedly connected to the fixed frame 9, and the input end of the air pump 12 is connected to the connecting pipe 14, and the connecting pipe 14 is connected to the air pump 12 arranged inside the adsorption box 10 through the second suction pipe 16. The cavity is connected, and a number of suction cups 11 are arranged on the top of the cavity. By setting the adsorption mechanism, the plate can be initially fixed, and the plate can be quickly separated from the conveying mechanism, which is convenient for people to weld.

[0027] In this embodiment, the tops of the left and right ends of the connecting pipe 14 are fixedly connected with the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com