A wastewater ozone dechlorination system and process

A waste water and ozone technology, applied in water pollutants, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high chlorine ion treatment cost, low ozone utilization rate, and large floor area. Achieve the effects of reducing solubility, promoting chlorine gas generation, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

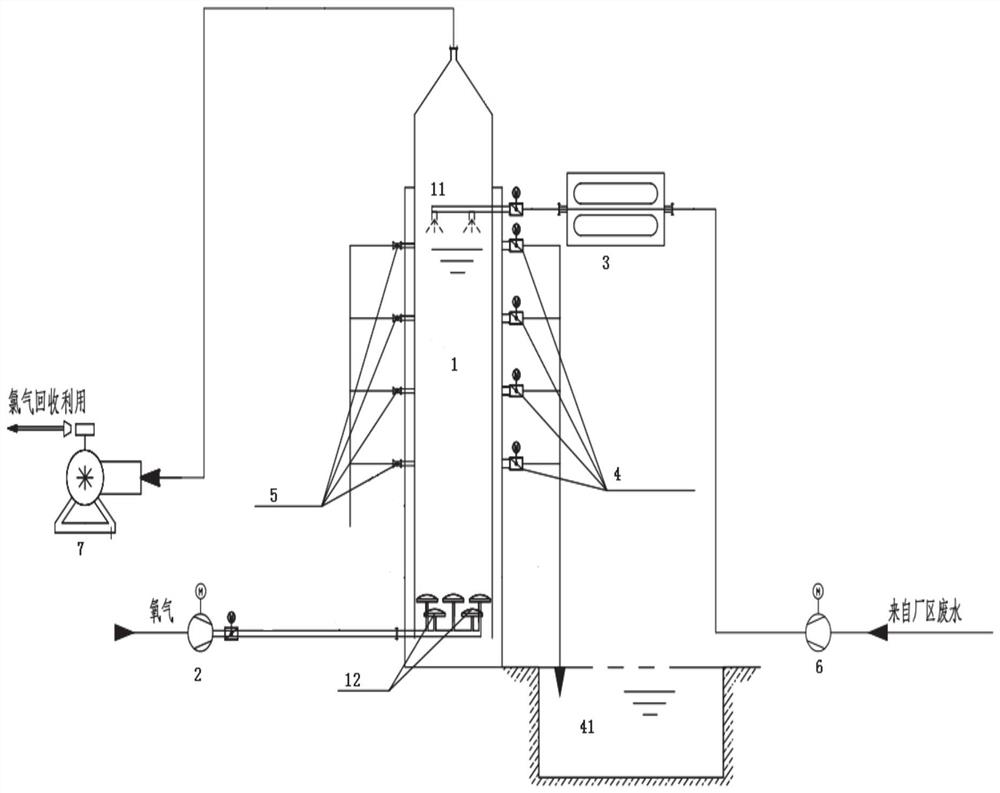

[0040] Such as figure 1As shown, the present embodiment provides a wastewater ozone dechlorination system, including a dechlorination device 1, an aeration pan 12 is installed at the bottom of the dechlorination device 1, and the aeration pan 12 is connected to the ozone generator 2, and the two are used for The ozone required for the reaction is provided, and the aeration disc 12 is a micro-nano aeration generating device, which is convenient for the ozone nano-bubbles to fully react with the chlorine ions in the wastewater. Ozone nano-bubbles form reverse contact with wastewater in water, and ozone and chlorine ions can fully contact and react to generate chlorine gas to be discharged. The aeration tray 12 is arranged in upper and lower layers to increase the contact area.

[0041] The upper part of the dechlorination device 1 is equipped with a nozzle 11, the waste water enters the dechlorination device 1 through the nozzle 11, and the nozzle 11 sprays the waste water, on ...

Embodiment 2

[0047] This embodiment provides a wastewater ozone dechlorination process. The wastewater ozone dechlorination process is carried out in the wastewater ozone dechlorination system described in Embodiment 1. Wastewater enters the chlorine removal process from the feed pipe through the wastewater heater 3 from the nozzle 11. In device 1, oxygen is prepared into ozone by ozone generator 2, ozone enters aeration pan 12, and reversely contacts with wastewater to oxidize chlorine ions in wastewater to chlorine gas, which is pumped from chlorine removal device 1 to chlorine gas discharge pipe by vacuum pump 7.

[0048] The waste water is atomized by the spray nozzle 11 and diffuses in the upper part of the dechlorination device 1. Since the waste water contains more chloride ions, the generated chlorine gas can be prevented from re-dissolving in the waste water. The nozzle 11 makes the chlorine ions evenly distributed in the waste water.

[0049] When the chlorine ion concentration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com