Measuring and processing system for adjusting overall lifting synchronism of steel structure

A technology of overall improvement and synchronization, applied in the processing of building materials, building structure, construction, etc., can solve the problems of a lot of manpower and time, increasing difficulty, and decreasing accuracy, so as to improve accuracy and reduce construction costs. risk, the effect of reducing the overall time span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by specific examples.

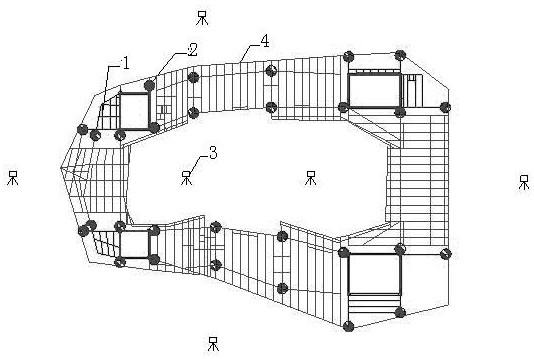

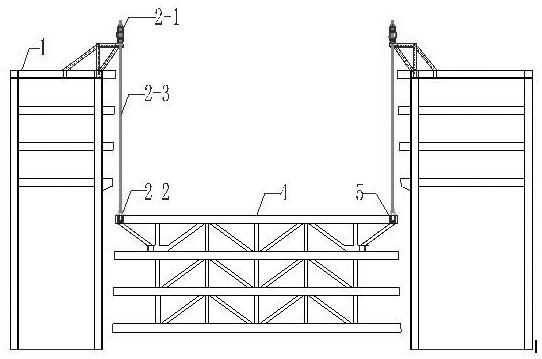

[0028] Such as figure 1 , figure 2 As shown, a measurement and processing method for adjusting the synchronization of the overall lifting of steel structures, including

[0029] Step 1. Determine the lifting point, specify the lifting support structure 1, the lifted structure 4, set the lifting point 2-1, the anchorage of the lowering point 2-3, and the steel strand 2-3;

[0030] Step 2. Determine the number and position of the measuring robots 3 according to the structural form and the layout of the hoisting points;

[0031] Step 3, installing the prism 5 at the position of the hoisting point for data acquisition;

[0032] Step 4, the prism 5 is automatically measured by the measuring robot 3, and the data is automatically transmitted to the data processing system in the control room;

[0033] Step 5. After the data is automatically processed, the synchronization data control indicators are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com