Automatic control system for unattended emulsion pump

An automatic control system and emulsion pump technology, applied in the control/regulation system, pump control, liquid level control and other directions, can solve the problem of high energy consumption, and achieve the effect of saving energy consumption, convenient control and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

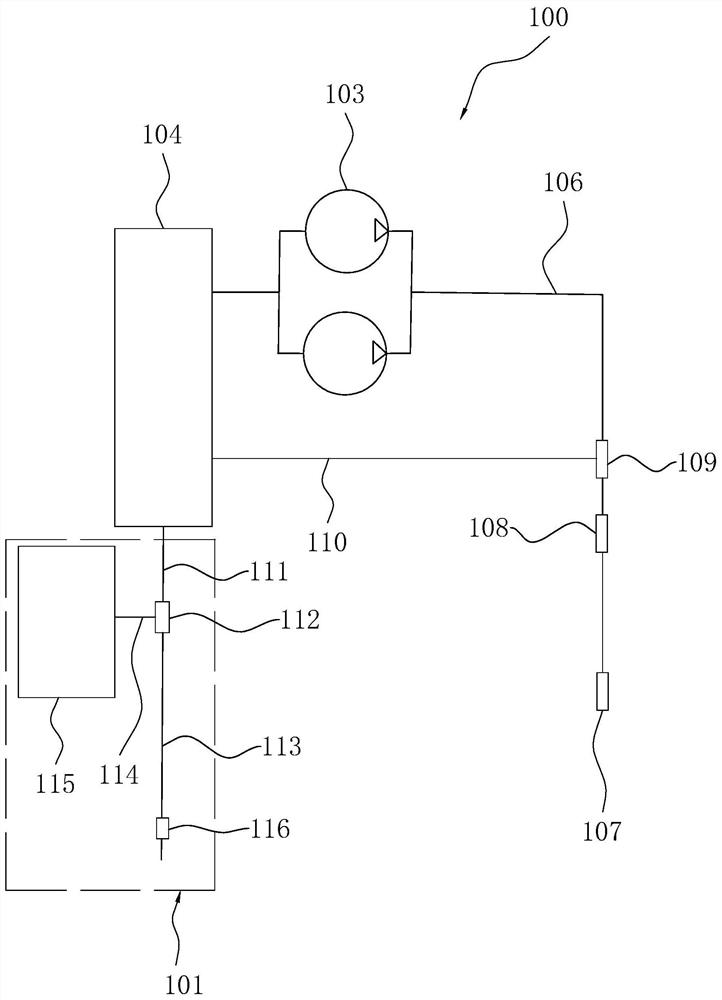

[0038] Example: such as figure 1 As shown, it is a kind of unattended emulsion pump automatic control system disclosed by the present invention, comprising:

[0039] The pressure supply device 100 is used to provide the emulsion with pressure for the hydraulic strut, so as to make the hydraulic strut work;

[0040] The liquid supply device 101 replenishes the consumed emulsion for the pressure supply device 100;

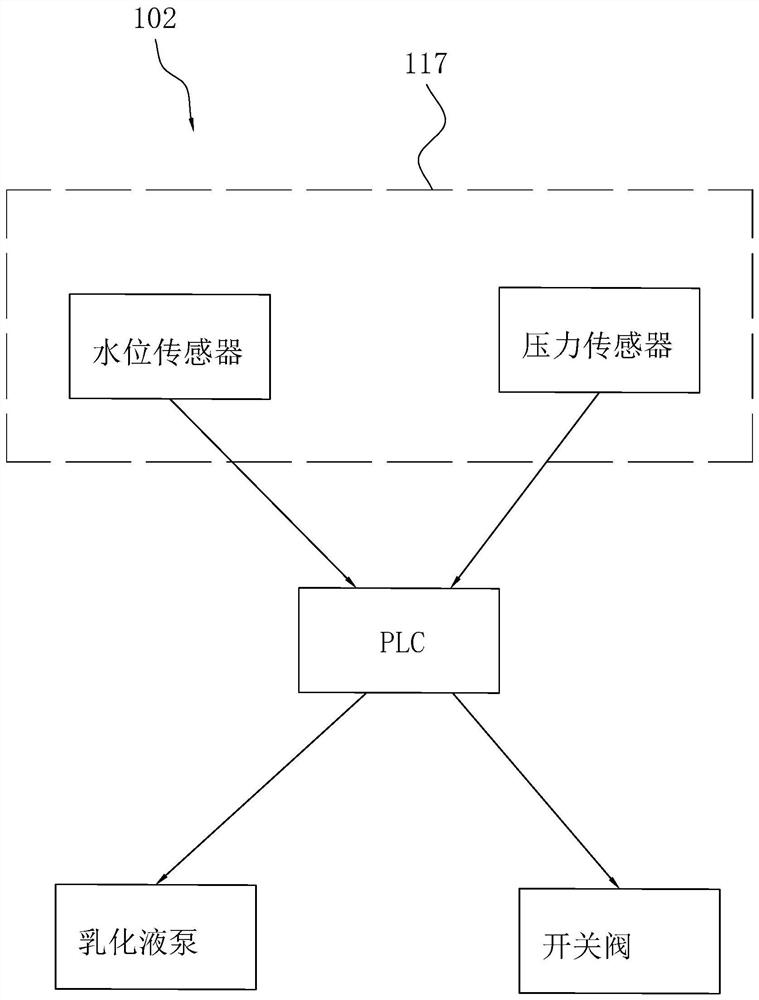

[0041] The control device 102 is used to control the start and stop of the pressure supply device 100 and the liquid supply device 101 to realize automatic control.

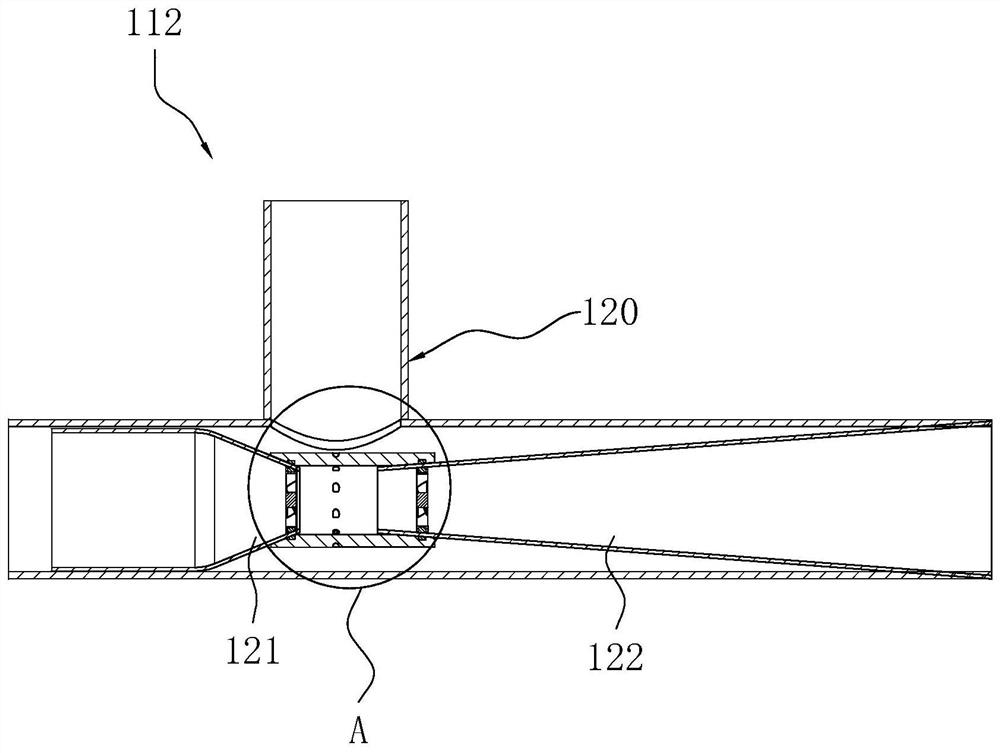

[0042] Such as figure 1As shown, the pressure supply device 100 includes an emulsion pump 103 and an emulsion tank 104 . There are two emulsion pumps 103, and the liquid inlets of both are communicated with the emulsion tank 104 through a three-way joint. The liquid outlets of the two emulsion pumps 103 are connected with a liquid supply pipe 106 through a three-way joint. One end of the liquid sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com