Rolling bearing fault detection method based on acoustic vibration signal fusion

A rolling bearing and signal fusion technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as difficult to detect faults, low amplitude at fault frequency, low signal-to-noise ratio, etc., to improve accuracy Improve performance and diagnostic efficiency, solve the problem of low signal-to-noise ratio, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

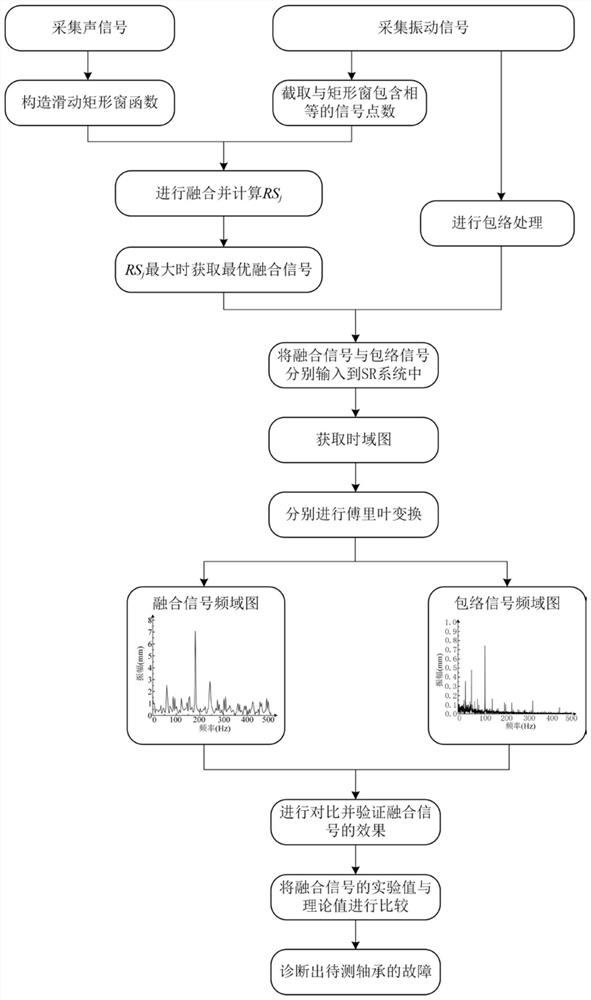

[0036] Such as figure 1 As shown, a rolling bearing fault detection method based on acoustic vibration signal fusion, including the following steps:

[0037] Step 1: Collect the vibration signal V' and the acoustic signal S' of the rolling bearing to be tested, and store them on the computer respectively; the sensor Q for collecting the vibration signal V' 1 Adsorbed on the bearing seat of the rolling bearing to be tested, the sensor Q that collects the acoustic signal S' 2 Installed on a plane 420mm from the end face of the bearing, and meet the sensor Q 2 The center point of is located on the axis of the bearing;

[0038] Step 2: Extract a segment containing N from the vibration signal V' v The vibration signal of consecutive signal points is taken as the vibration signal V to be detected, that is, V={V[u]|u=1,2,...,N v}; Extract a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com