Device for measuring dynamic elasticity modulus of soft deadening felt

A dynamic elasticity, measuring device technology, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Achieve the effect of reducing measurement error, reducing error and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given, but the protection scope of the present invention is not limited to the following embodiments.

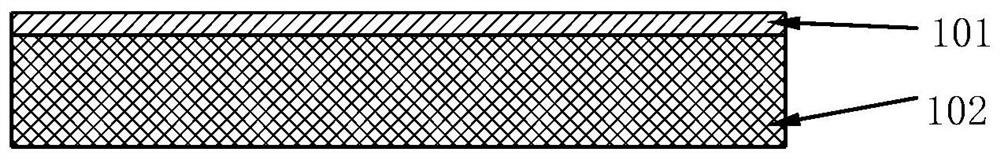

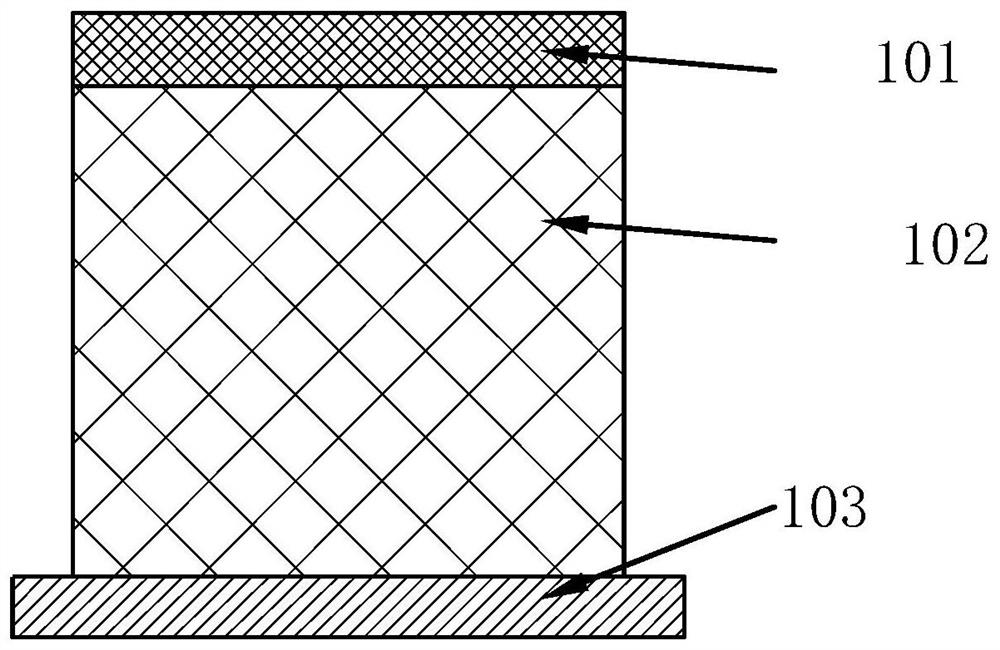

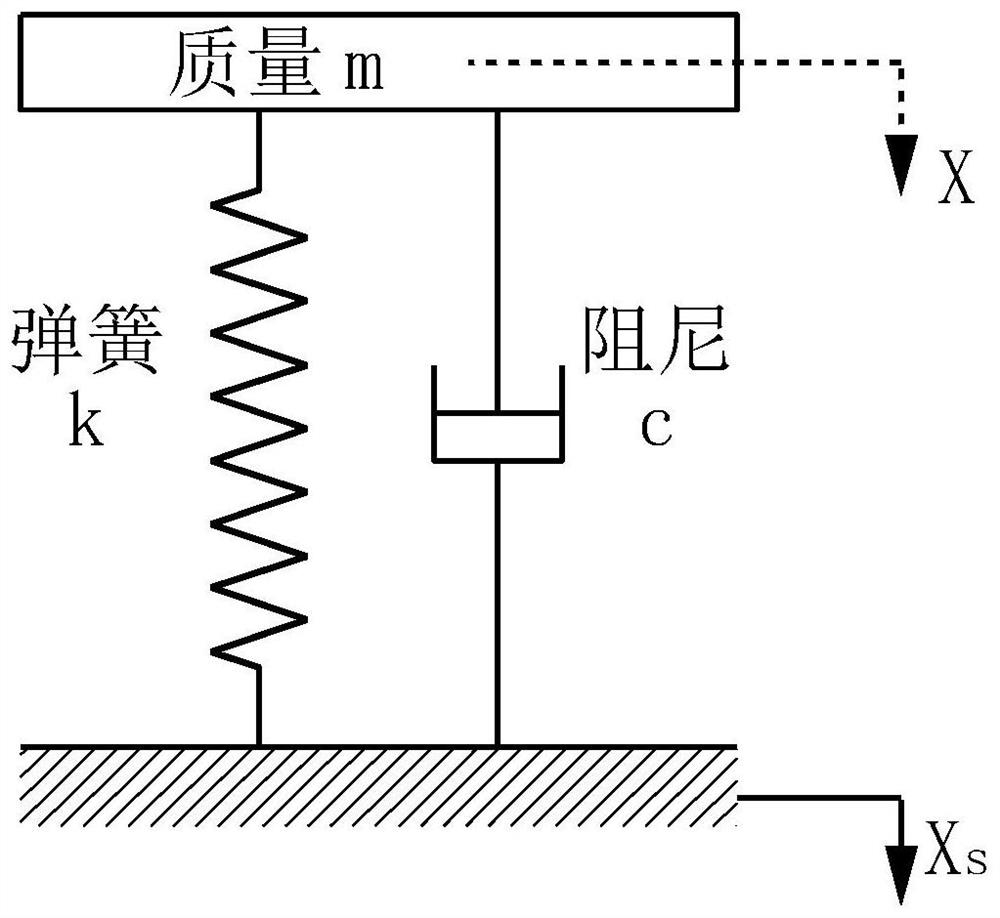

[0041] A device for measuring dynamic elastic properties of soft sound insulation felt, such as Figure 4 As shown, it includes an upper vibration mass 1, a lower vibration base plate 4, an excitation table 6, an upper acceleration sensor 2, a lower acceleration sensor 5 and a measurement module, and the lower vibration base plate 4 is rigidly connected to the vibration head of the vibration excitation table 6, as Figure 6 As shown, the sample block 3 to be tested is clamped between the upper vibrating mass 1 and the lower vibrating base 4, the upper acceleration sensor 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com