Waste tire crushing device and crushing method thereof

A crushing device and waste tire technology, applied in recycling technology, grain processing, mechanical material recycling, etc., can solve the problems of rubber flammability, visual damage, unreasonable structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

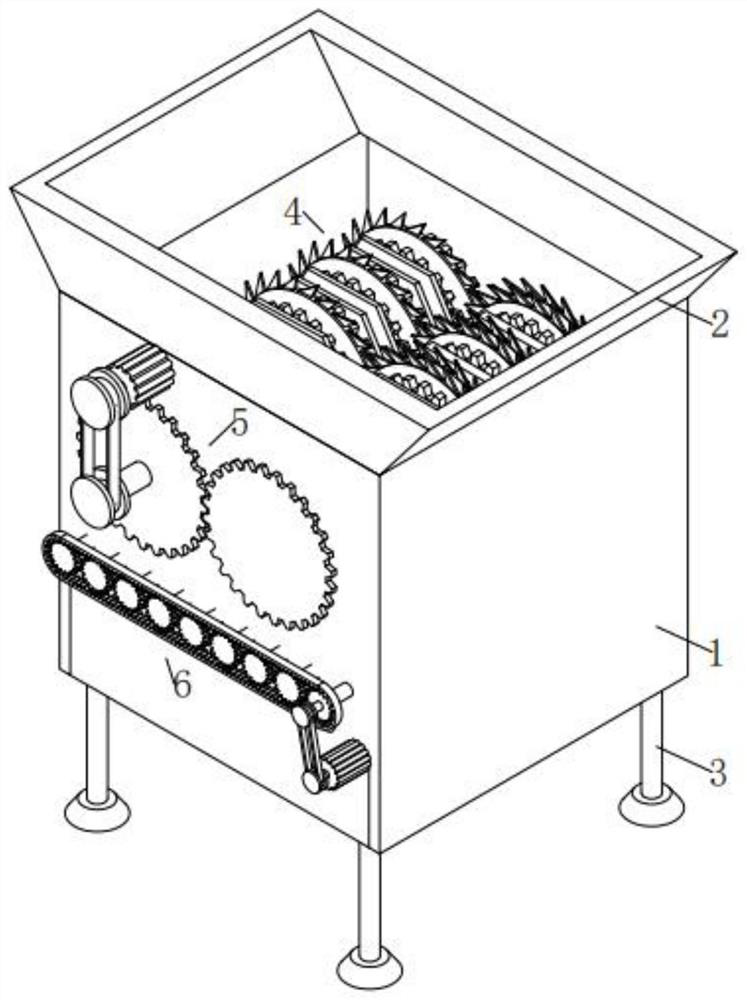

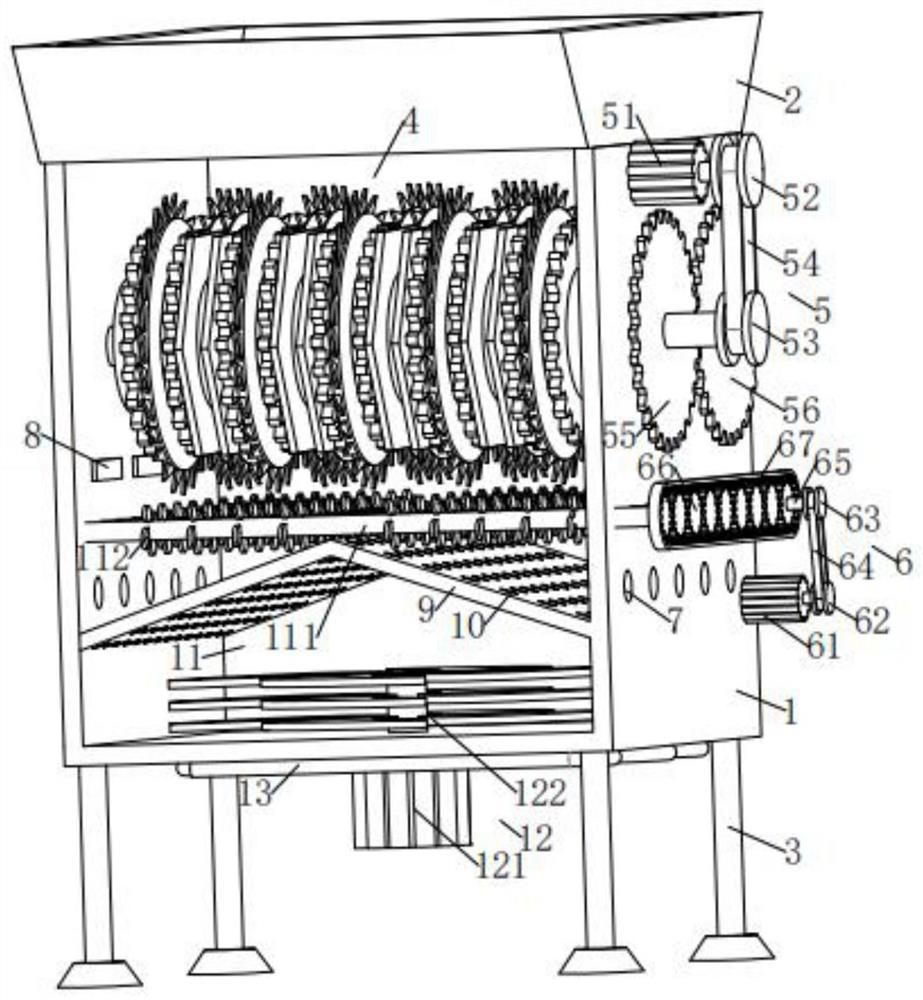

[0055] see Figure 1-5 , a waste tire crushing device, comprising a box body 1 with a feed inlet 2 fixedly arranged on the top, support feet 3 fixedly arranged at the four corners of the bottom, and a discharge outlet (not shown in the figure) arranged at the rear end, all of which It is the common knowledge of those skilled in the art, so it will not be repeated here, and the present invention also includes:

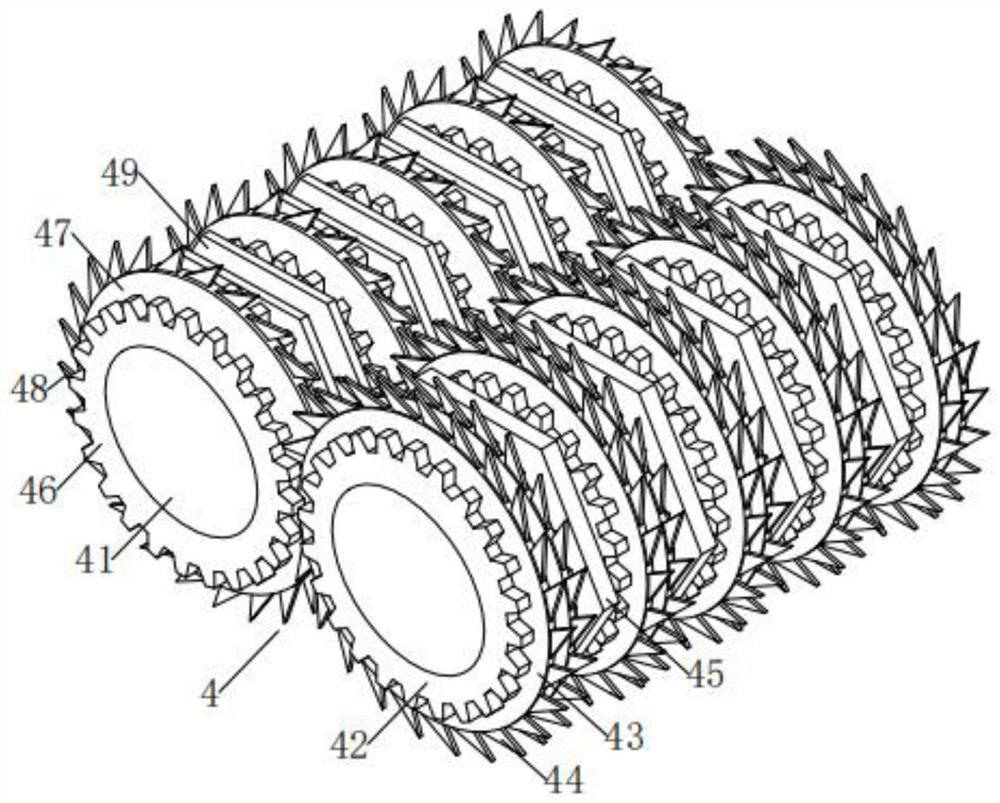

[0056] The crushing mechanism 4 arranged in the feed port 2, the crushing mechanism 4 includes a first crushing mechanism and a second crushing mechanism, the first crushing mechanism and the first crushing mechanism both include a crushing shaft and a crushing roller 41, and the crushing roller 41 passes through the crushing shaft It rotates and cooperates with the inner wall of the box body 1, and the other ends of the two crushing shafts respectively pass through the box body 1 and extend to its front side. Including multiple sets of first crushing gears 42, multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com