Fly ash cooled pellet ball press machine

A ball press and ball machine technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problem of low ball forming rate of ball presses, reduce the probability of loose or unextruded molding, improve Squeeze effect, the effect of prolonging the squeezing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

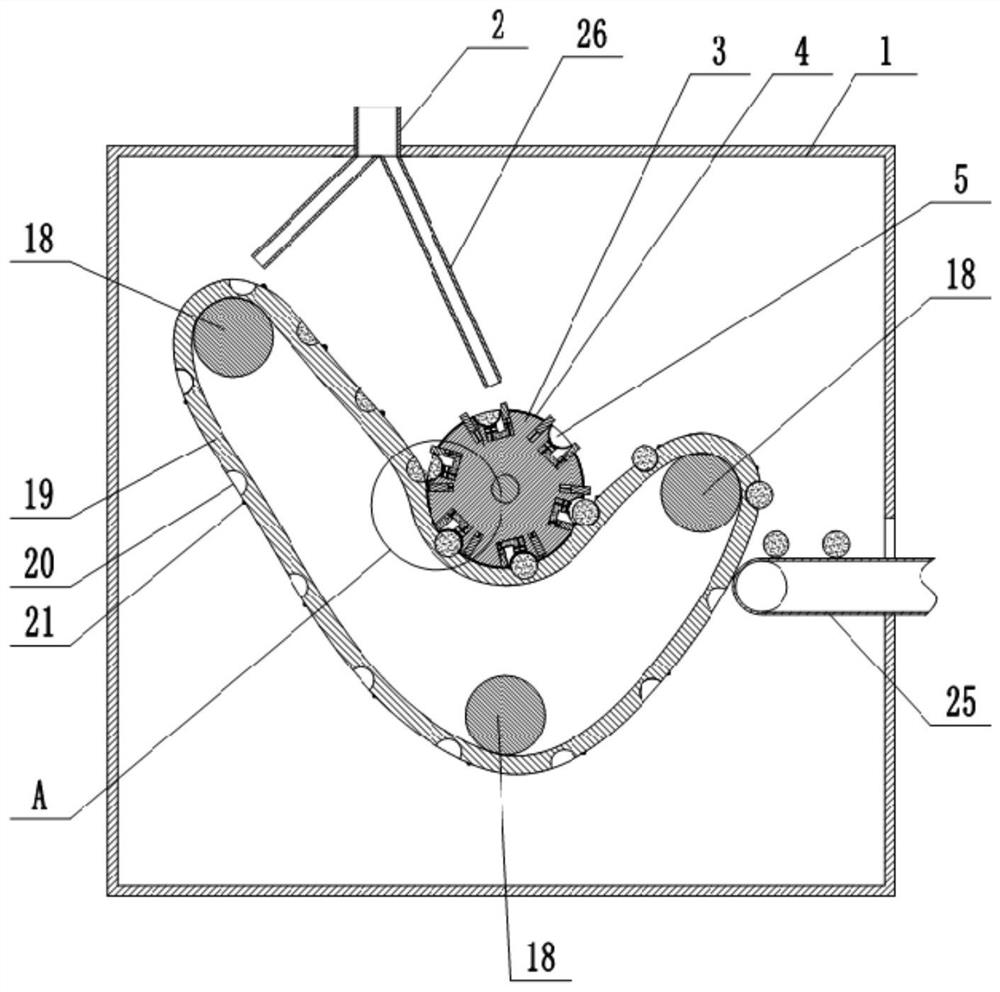

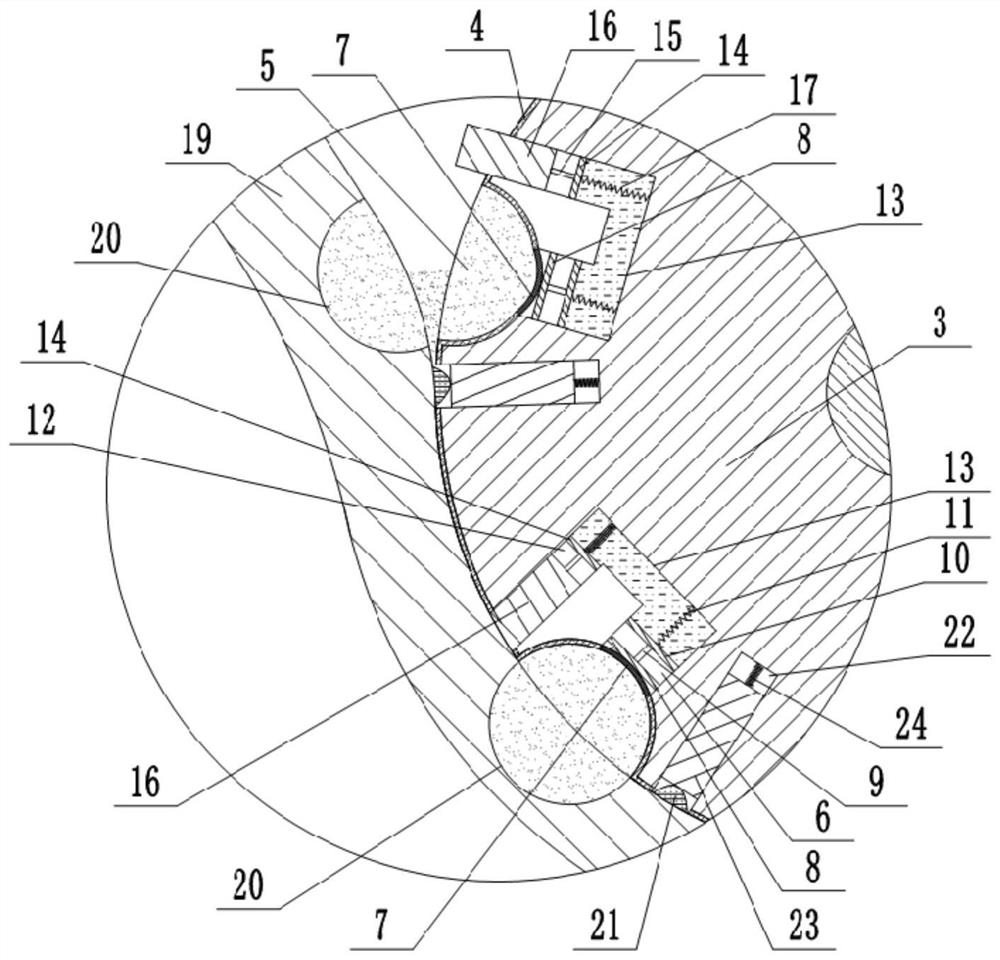

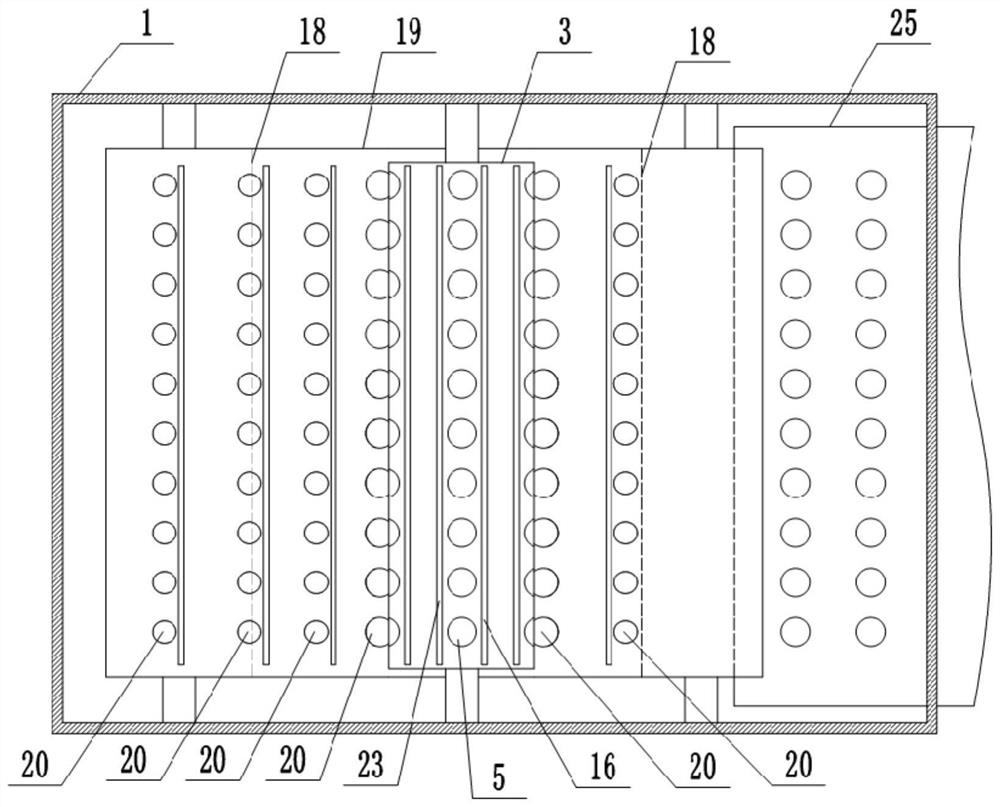

[0036] The dedusting ash cooling ball briquetting machine is mainly composed of a box body 1, a feed inlet 2, a driving roller 3, a roller sleeve 4, a first ball socket 5, a pushing unit, a driven roller 18, a transmission belt 19, and a driving unit. combined with figure 1As shown, the feed port 2 is set on the left side of the top of the box body 1, and the cross section of the feed port 2 is a long rectangular shape. There are two feed branch pipes 26 connected to the bottom of the feed port 2, and one of the feed branch pipes 26 The outlet end is aligned with the upper left part of the transmission belt 19, and the outlet end of the other feeding branch pipe 26 is positioned at the upper left part of the driving roller 3. The cross-sections of the two feeding branch pipes 26 are also elongated rectangles and extend along the width direction of the transmission belt 19 . An intermittent conveyor (not shown in the figure) is installed above the casing 1, and the intermitten...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is: in this embodiment, in combination with the attached figure 2 As shown, the driving roller 3 is also provided with a plurality of second sliding ports 22, the second sliding ports 22 correspond to the first sliding ports one by one, and the first sliding ports can be connected with the second sliding ports 22 to form a channel. The second sliding port 22 is slidably and sealedly connected with a protective plate 23, and one end of the protective plate 23 is fixedly connected with a third elastic member 24, and the third elastic member 24 is fixedly connected with the bottom end of the first sliding port, and the third elastic member 24 It is a compression spring; the other end of the protective plate 23 passes through the first sliding opening and stretches out the roller sleeve 4 . When the third elastic member 24 is not compressed, the distance of the protective plate 23 above the roller sleeve 4 is 0.5-1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com