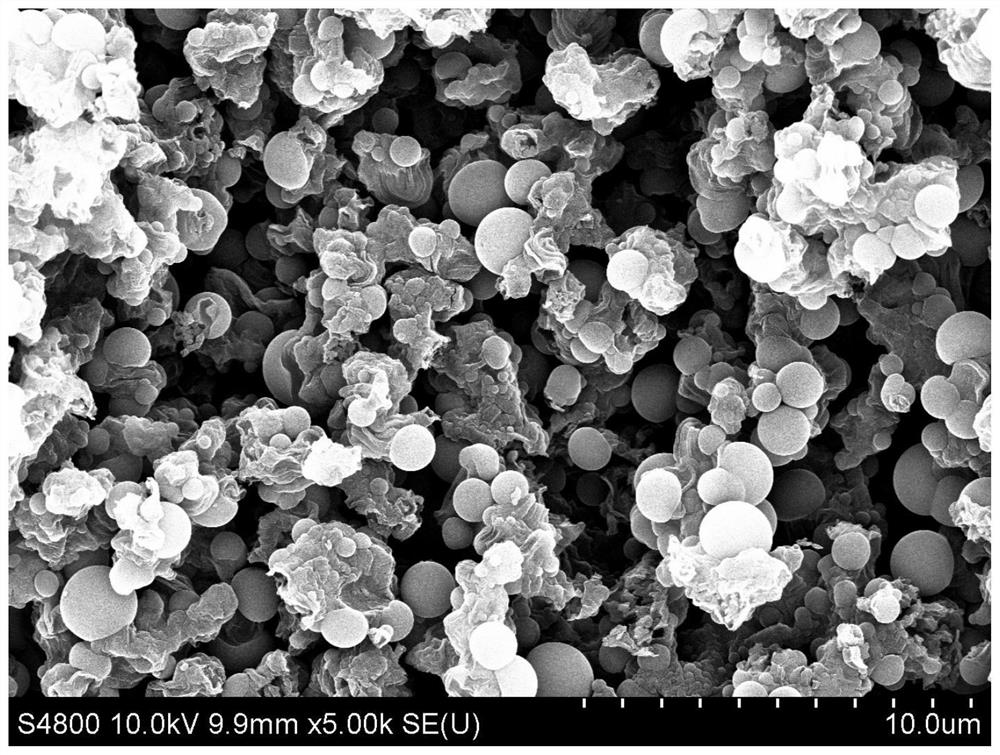

An airgel-derived nitrogen-phosphorus co-doped porous carbon and its preparation method and application

A co-doping and porous carbon technology, applied in the field of porous carbon materials, can solve the problems of limited commercial application, resource shortage, low durability, etc., and achieve the effect of unique and ingenious method, high production efficiency and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The embodiment of the present invention is a method for preparing airgel-derived nitrogen and phosphorus co-doped porous carbon. The specific steps are as follows:

[0037] S1. Add 2.0 g of block copolymer P123 to 60.0 mL of 0.25 mol / L phytic acid aqueous solution, and stir at 35°C for 5 hours until dissolved, then add 1.0 mL of pyrrole, and stir and mix for 2 minutes to obtain a milky white uniform dispersion. The milky white dispersion was transferred to a high-pressure reactor, and hydrothermally reacted at 180°C for 12 hours to obtain a nitrogen-phosphorus co-doped hydrogel. After washing the obtained nitrogen-phosphorus co-doped hydrogel with ultrapure water for several times, Freeze drying at -55°C for 72 hours to obtain nitrogen and phosphorus co-doped airgel;

[0038] S2. Put the prepared nitrogen-phosphorus co-doped airgel into a quartz boat, use a tube furnace, and raise the temperature at a rate of 5°C / min under a nitrogen atmosphere. After raising the temper...

Embodiment 2

[0041] The embodiment of the present invention is a method for preparing airgel-derived nitrogen and phosphorus co-doped porous carbon. The specific steps are as follows:

[0042] S1. Add 2.0 g of block copolymer P123 to 60.0 mL of 0.25 mol / L phytic acid aqueous solution, and stir at 35°C for 5 hours until dissolved, then add 1.0 mL of pyrrole, and stir and mix for 2 minutes to obtain a milky white uniform dispersion. The milky white dispersion was transferred to a high-pressure reactor, and hydrothermally reacted at 180°C for 12 hours to obtain a nitrogen-phosphorus co-doped hydrogel. After washing the obtained nitrogen-phosphorus co-doped hydrogel with ultrapure water for several times, Freeze drying at -55°C for 72 hours to obtain nitrogen and phosphorus co-doped airgel;

[0043] S2. Put the prepared nitrogen-phosphorus co-doped airgel into a quartz boat, use a tube furnace, and raise the temperature at a rate of 5°C / min under a nitrogen atmosphere. When the temperature ris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com