In-situ growth self-supporting nickel-oxygen co-doped carbon nanotube catalyst and preparation method and application thereof

An in-situ growth, carbon nanotube technology, applied in the field of electrochemistry, can solve the problems of high risk factor, a large amount of waste acid, increase process cost, etc., and achieve the effects of low energy consumption, uniform co-doping, and saving preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

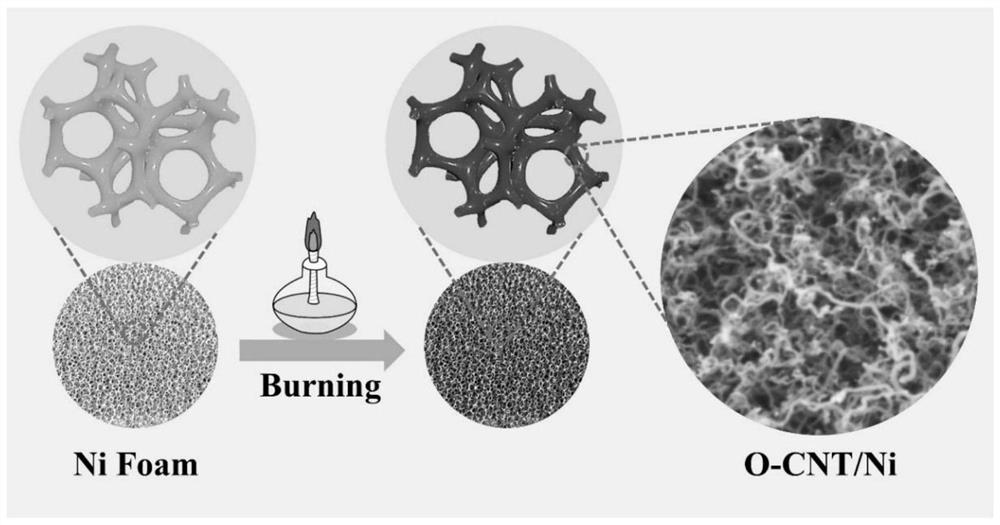

[0029] Take a square nickel foam with a side length of 5 cm, wash it with 0.1M HCl solution and ultrapure water in order to remove the oxide layer and other impurities, and dry it at room temperature after washing. The dried nickel foam is placed on an alcohol lamp (70% ethanol volume concentration) and calcined for 30 minutes to obtain a self-supporting nickel-oxygen co-doped carbon nanotube catalyst grown in situ.

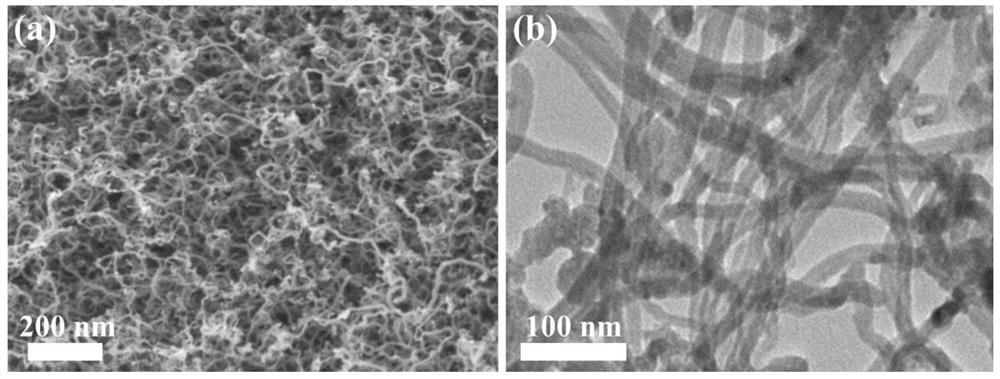

[0030] figure 2 It is the topography figure of the self-supporting nickel-oxygen co-doped carbon nanotube catalyst obtained in this embodiment, wherein figure 2 (a) is the SEM picture, figure 2 (b) is a TEM image. It can be seen from the figure that the morphology of the obtained product is a three-dimensional network carbon nanotube structure.

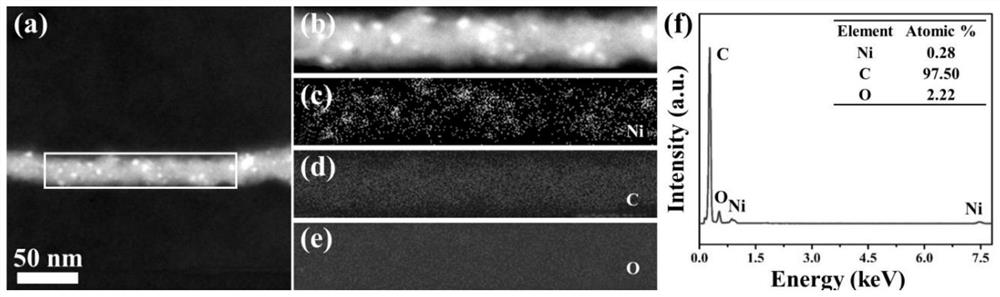

[0031] image 3 It is the morphology and element distribution diagram of the self-supporting nickel-oxygen co-doped carbon nanotube catalyst obtained in this example, wherein image 3 (a) is the HRTEM map, imag...

Embodiment 2

[0039] Take a square nickel foam with a side length of 10 cm, wash it successively with 0.1M HCl solution and ultrapure water to remove the oxide layer and other impurities, and dry it at room temperature after washing. The dried nickel foam was calcined on an alcohol lamp (80% ethanol volume concentration) for 40 min to obtain a self-supporting nickel-oxygen co-doped carbon nanotube catalyst grown in situ.

[0040] After characterization and testing, the catalyst obtained in this example also has a three-dimensional network carbon nanotube structure, and has excellent electrocatalytic H production 2 o 2 performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com