Super-thick material layer distribution method

A thick material layer and cloth technology, which is applied in the field of ultra-thick material layer cloth, can solve the problems such as the inability to meet the requirements of the material layer air permeability, and achieve the effects of good sintered ore quality, increased particle size, and reduced extrusion damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

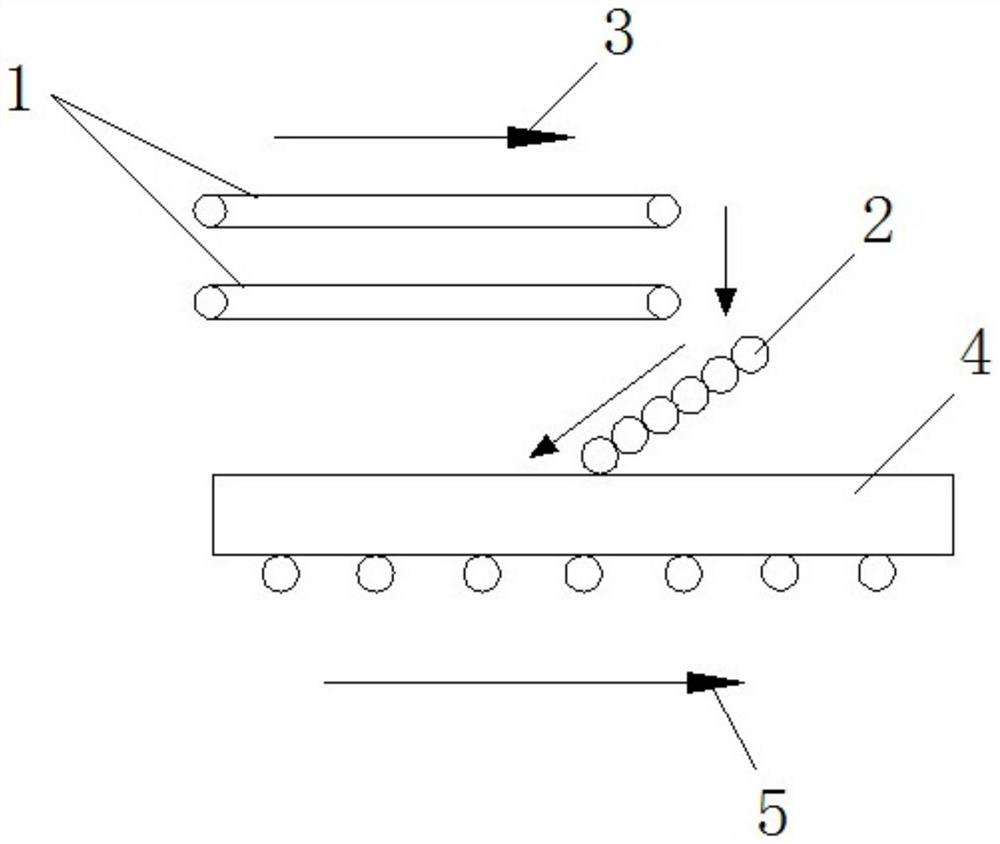

[0036] This embodiment provides a specific implementation of an ultra-thick material layer distributing equipment, such as figure 1 As shown, it includes: conveyor 1 and multi-roller distributor 2. Wherein said feeder 1 has two sets that are arranged in parallel and spaced up and down, and the width of the upper and lower two feeder 1s is 2600mm wide. In addition, as an alternative embodiment, there may be more than two conveyors 1 as required, and the width of the conveyor 1 may be between 2600 mm and 3000 mm.

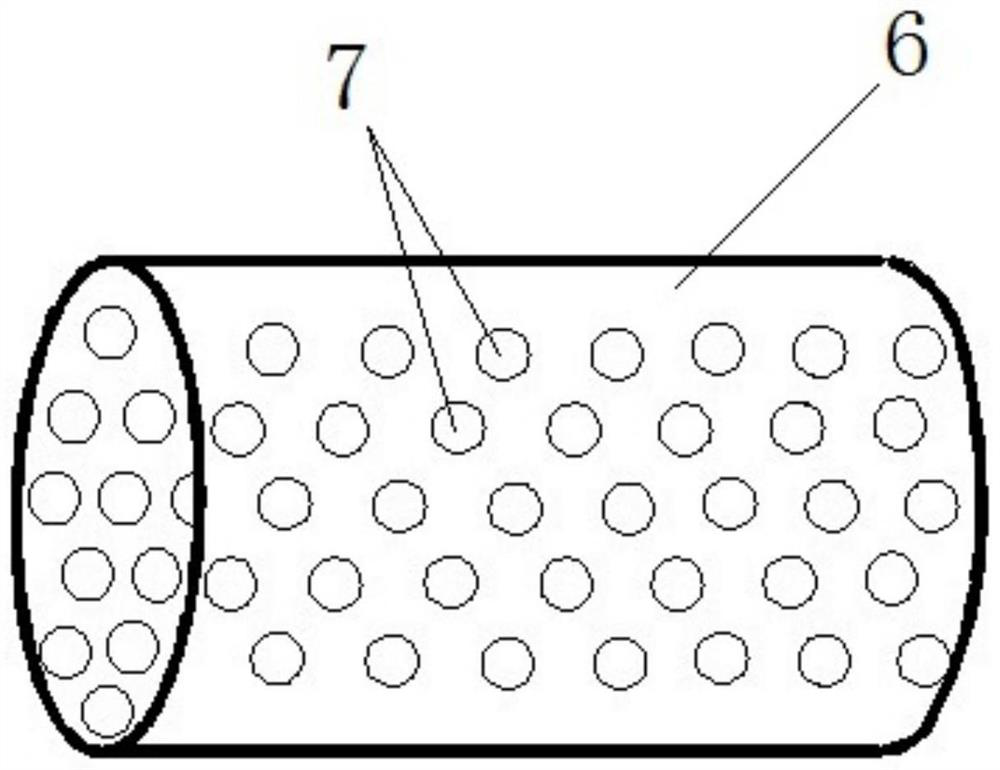

[0037] Such as figure 1 As shown, the multi-roller distributor 2 is received below the outlet of the conveyor 1, the multi-roller distributor 2 is specifically: a six-roller distributor, and the six-roller distributor has six rotatable rollers 6, Each roller 6 has a diameter of 250 mm. In addition, as an alternative embodiment, the multi-roller distributor 2 can also be other multi-roller distributors 2 except the six-roller distributor, and the diameter of each ro...

Embodiment 2

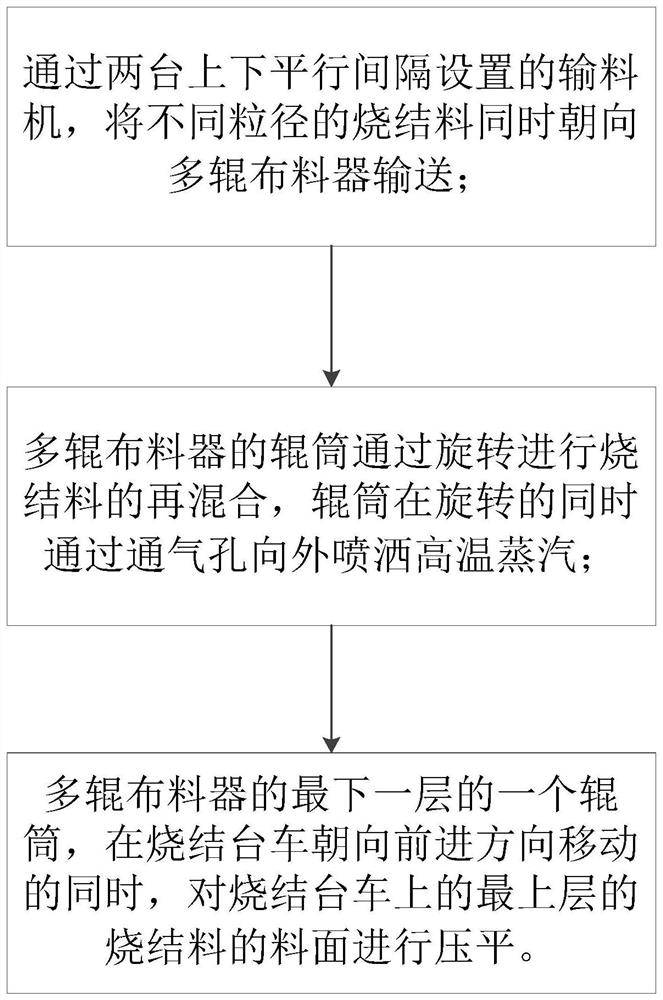

[0042] This embodiment provides a specific implementation of a method for distributing an ultra-thick material layer, and the equipment for distributing an ultra-thick material layer as described in Example 1 can be used, specifically as image 3 shown, including the following steps:

[0043]Step 1: Convey the sintered materials with different particle sizes towards the multi-roller distributor 2 at the same time through two conveyors 1 arranged in parallel and spaced up and down; specifically, the conveyor 1 located above is used to convey the particle size is about 3mm The ore return, the conveyor 1 located below is used to transport the sintered material after secondary mixing, and the returned ore and sintered material fall from the conveyor 1 at the same time, which is conducive to uniform mixing.

[0044] Step 2: During the distributing process, the roller 6 of the multi-roller distributor 2 rotates, and the sintering material is remixed through the rotation of the rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com