Floating type water level alarm device for hydropower station

A water level alarm, floating technology, applied in measuring devices, buoy liquid level indicators, instruments, etc., can solve the problems of long sampling period, frequent fluctuations in the conduction and disconnection of the alarm device, and reducing the immediacy and accuracy of the alarm device. , to improve the working stability and service life, improve the monitoring stability and service life, and improve the water barrier effect and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

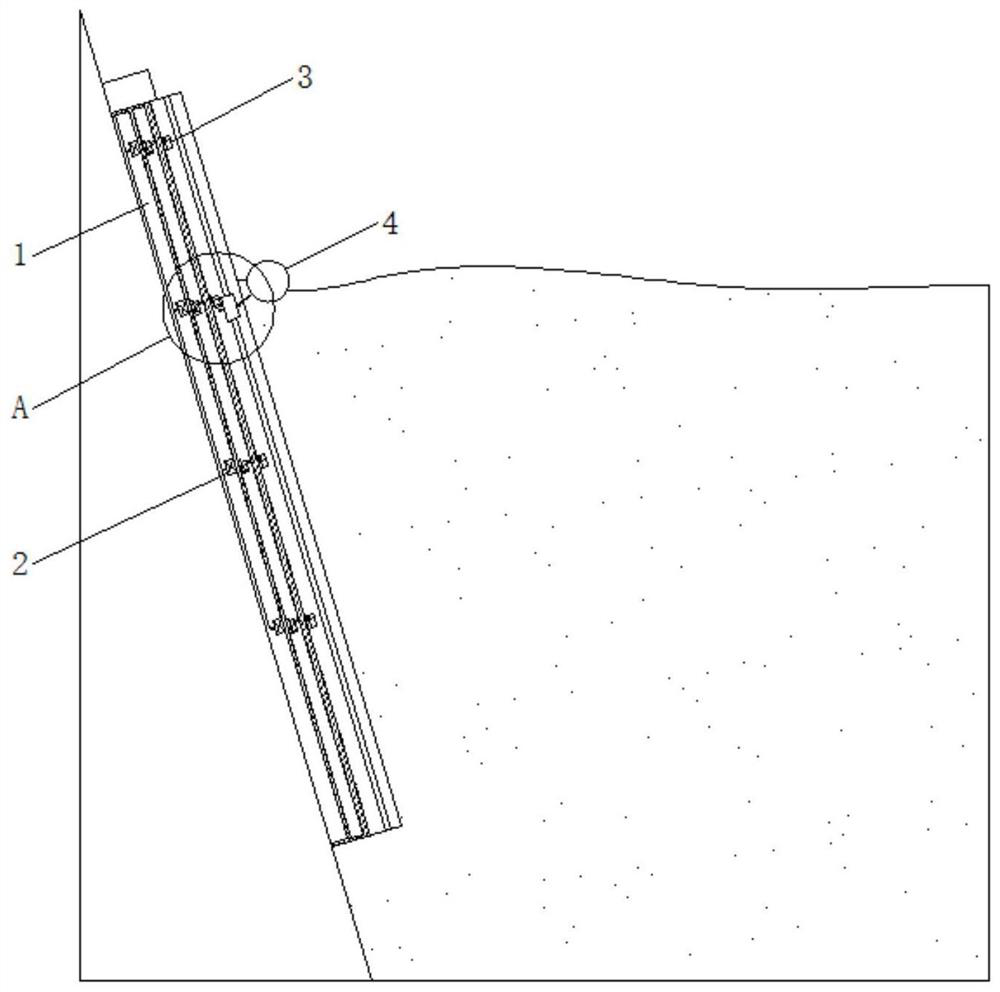

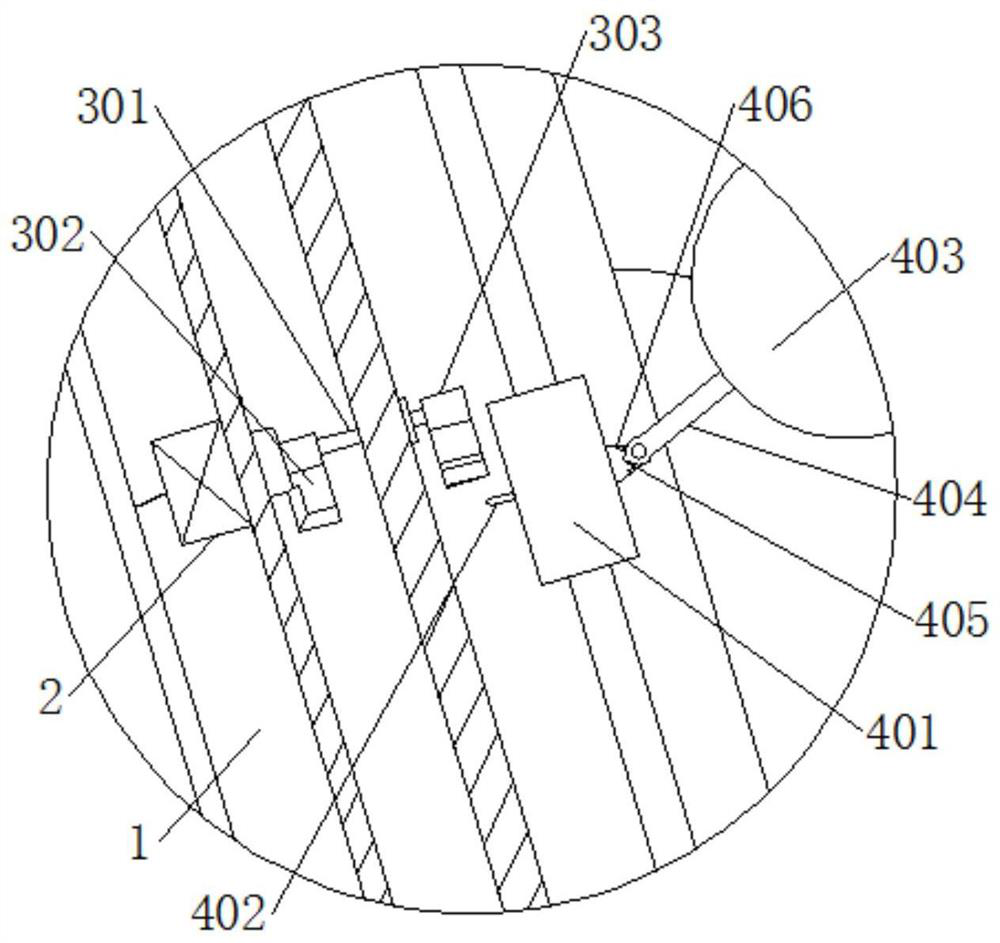

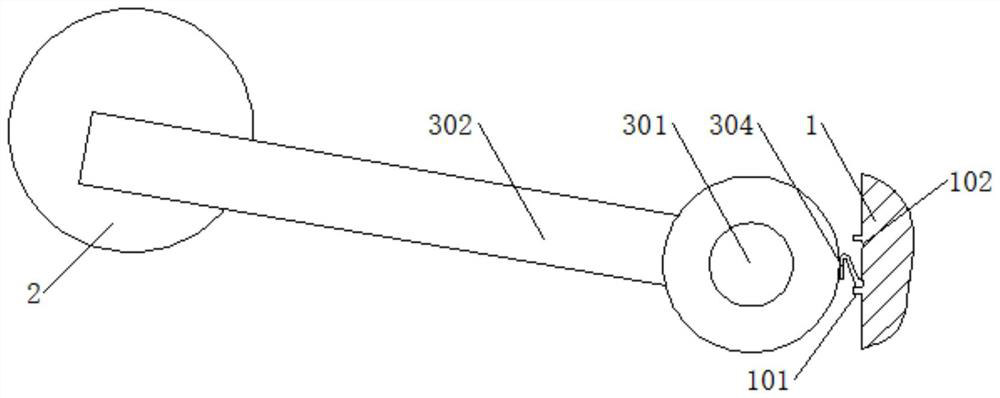

[0029] Example. A floating water level alarm device for a hydropower station, which consists of figure 1 As shown, it includes a measuring frame body 1 fixed on the embankment. The surface of the measuring frame body 1 is provided with a floating assembly 4 that can be lifted. The inside of the measuring frame body 1 forms a sealed chamber. A number of water level alarm switches 2 are distributed at intervals. One side of the water level alarm switch 2 is provided with a swing rod assembly 3 that is rotatably connected to the sealed chamber. One end of the swing rod assembly 3 is in contact with the water level alarm switch 2. The end of the swing rod assembly 3 extends to The outside of the sealed chamber is in contact with the floating component 4 , and the pendulum component 3 and the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com