New energy flame-retardant cable

A flame-retardant cable and new energy technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of complex materials and structures, and improve the difficulty of cable processing, and achieve the effects of simple structure, improved production efficiency, and good cable core protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

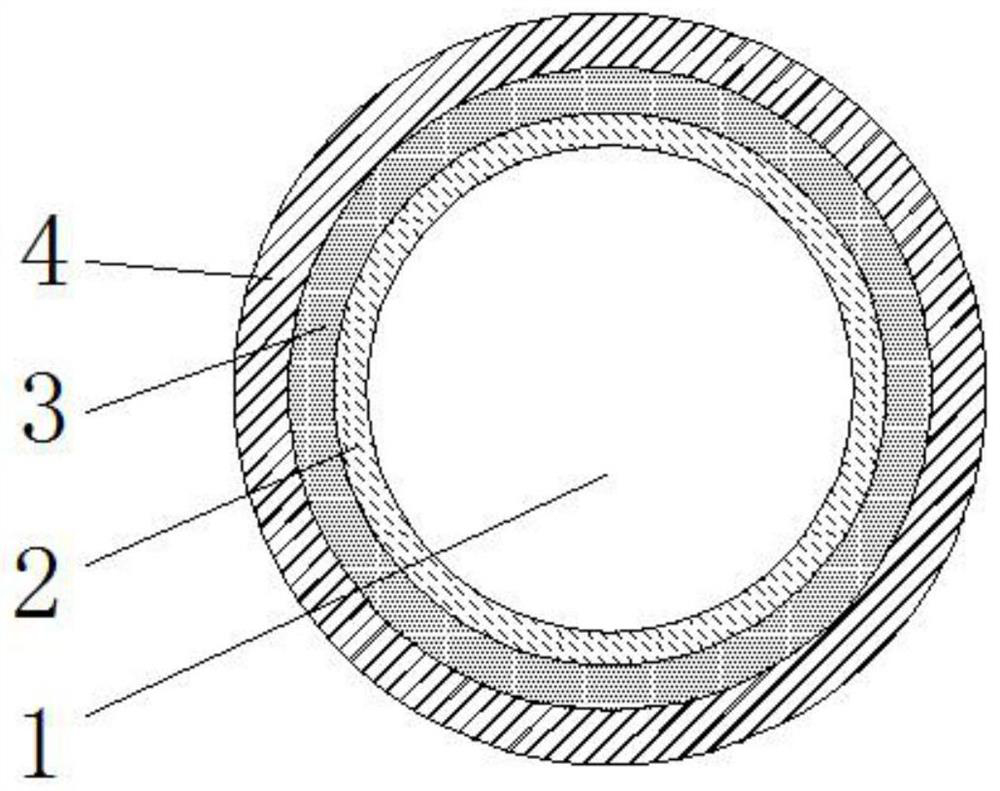

[0031] Such as figure 1 A new energy flame-retardant cable is shown, including a cable core 1 located at the center of the cable and a sheath layer 4 covering the surface of the cable; a heat shrinkable layer 2 is provided outside the cable core 1, and the heat shrinkable The outer side of the shrinkable layer 2 is provided with a flame retardant layer 3, and in the initial state, the outer side of the heat shrinkable layer 2 is completely attached to the inner side of the flame retardant layer 3;

[0032] The heat-shrinkable layer 2 is made of heat-shrinkable material. Heat-shrinkable material, also known as polymer memory material, is a kind of intelligent material combined with polymer material and radiation processing technology. The shape memory effect of polymer materials is the basic principle of manufacturing heat shrinkable materials. The polyolefin substrate undergoes a cross-linking reaction after irradiation, endowing the material with insoluble and infusible cha...

Embodiment 2

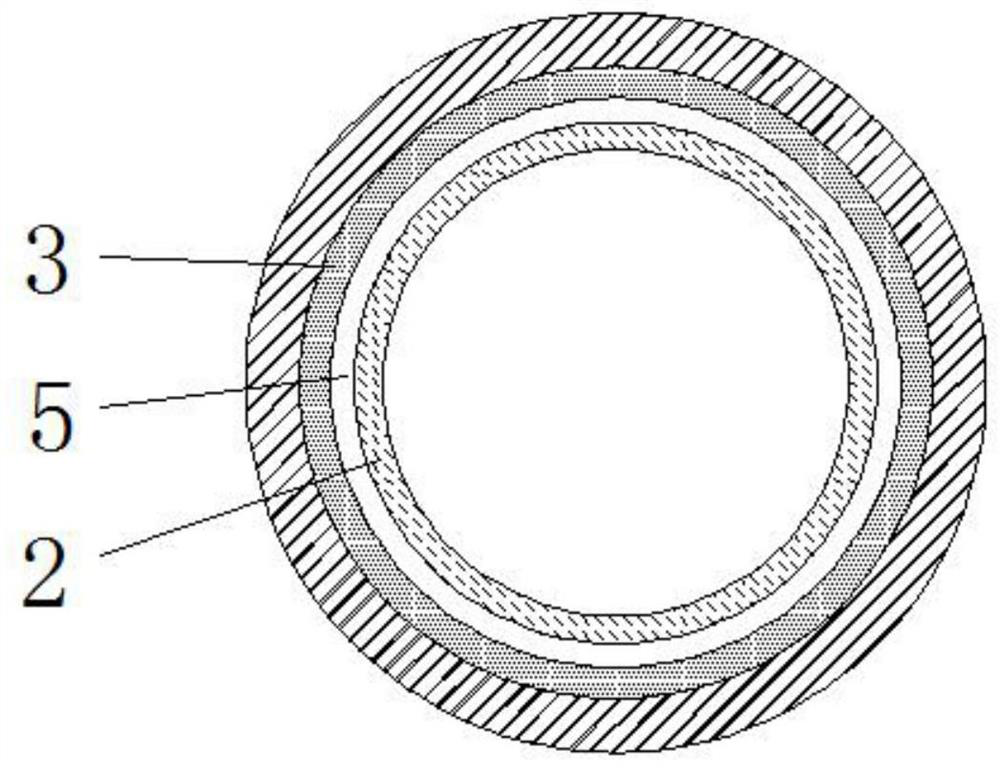

[0037] The difference between this embodiment and embodiment 1 is:

[0038]In this embodiment, the material of the flame-retardant layer 3 is an environment-friendly flame-retardant wood material. Flame-retardant wood materials have a flame-retardant function and can meet the design needs, and the flame-retardant materials are environmentally friendly materials, which meet people's increasing awareness of environmental protection, safety, and health.

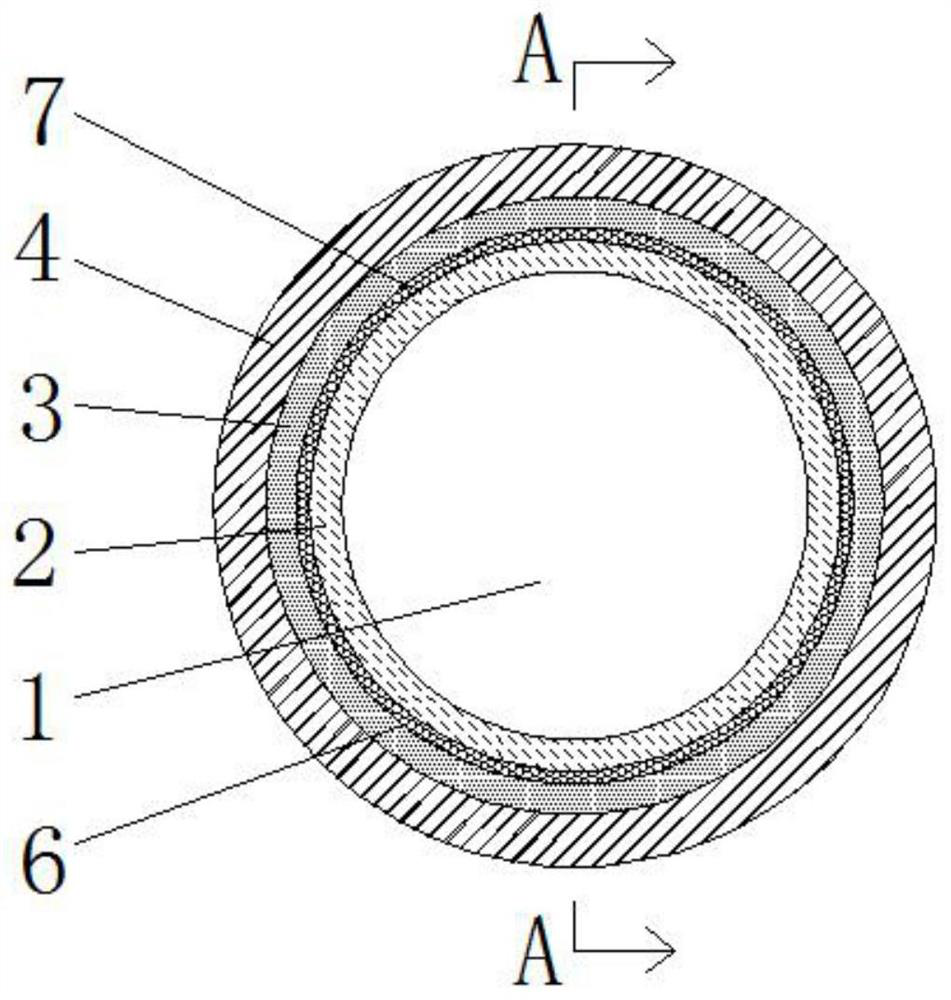

[0039] In this example, if image 3 and Figure 4 As shown, the inner surface of the flame-retardant layer 3 is provided with circular embedding grooves 6 at equal intervals along its length direction, and each embedding groove 6 is fixedly embedded with a ring-shaped heat-expandable tire 7, In the initial state, the inner surface of the thermally expandable tire 7 is flush with the inner surface of the flame-retardant layer 3 . Based on the heat shrinkage of the heat shrinkable layer 2 and the formation of a gap between the ...

Embodiment 3

[0043] The difference between this embodiment and embodiment 2 is:

[0044] In this embodiment, the flame retardant layer 3 is made of environmentally friendly flame retardant plastic. Flame-retardant plastics have a flame-retardant function, which can meet the design needs, and the flame-retardant materials are environmentally friendly materials, which meet people's increasing awareness of environmental protection, safety, and health.

[0045] In this example, if Figure 7 As shown, the inside of the heat-shrinkable layer 2 is provided with a uniform heat-conducting layer 8 located outside the cable core 1. The uniform heat-conducting layer 8 is a wire wrapping layer made of heat-conducting metal. The cable core 1 and the uniform heat-conducting layer A gap is left between the layers 8 . The uniform heat-conducting layer can make the heat emitted by the cable core evenly transfer to the heat-shrinkable layer, which is conducive to the uniform shrinkage and deformation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com