Motor rotor and motor

A technology of rotors and rotor cores, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as increasing the mechanical strength of rotors, achieve the effects of improving motor efficiency, reducing motor noise, and improving operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

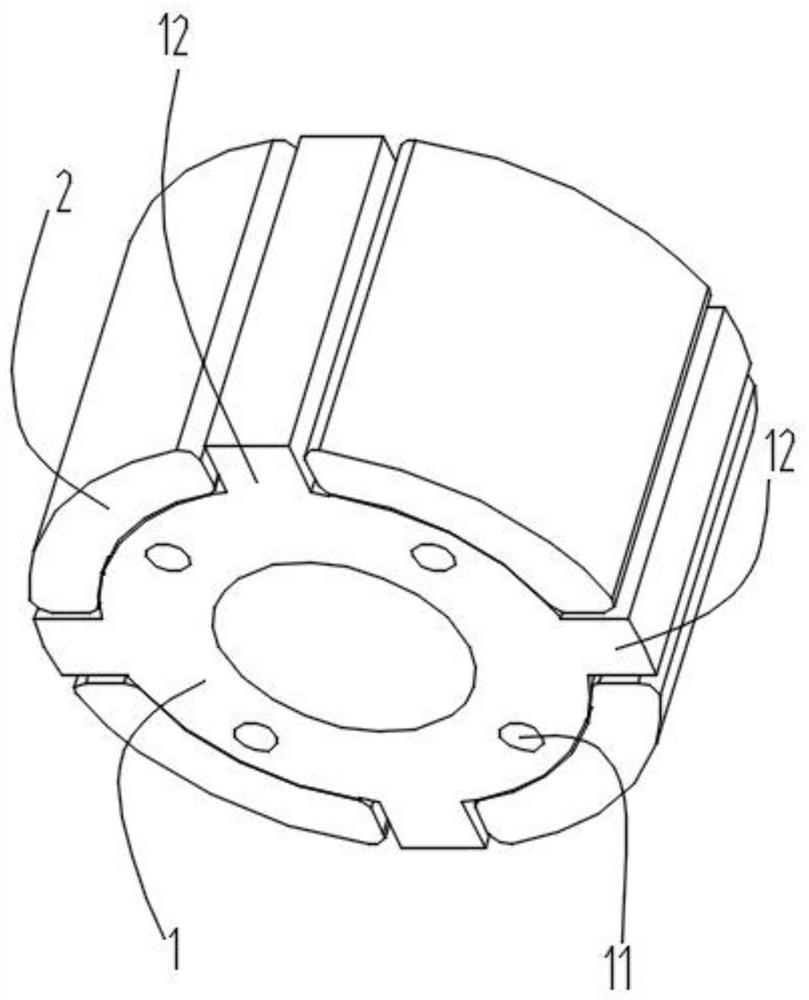

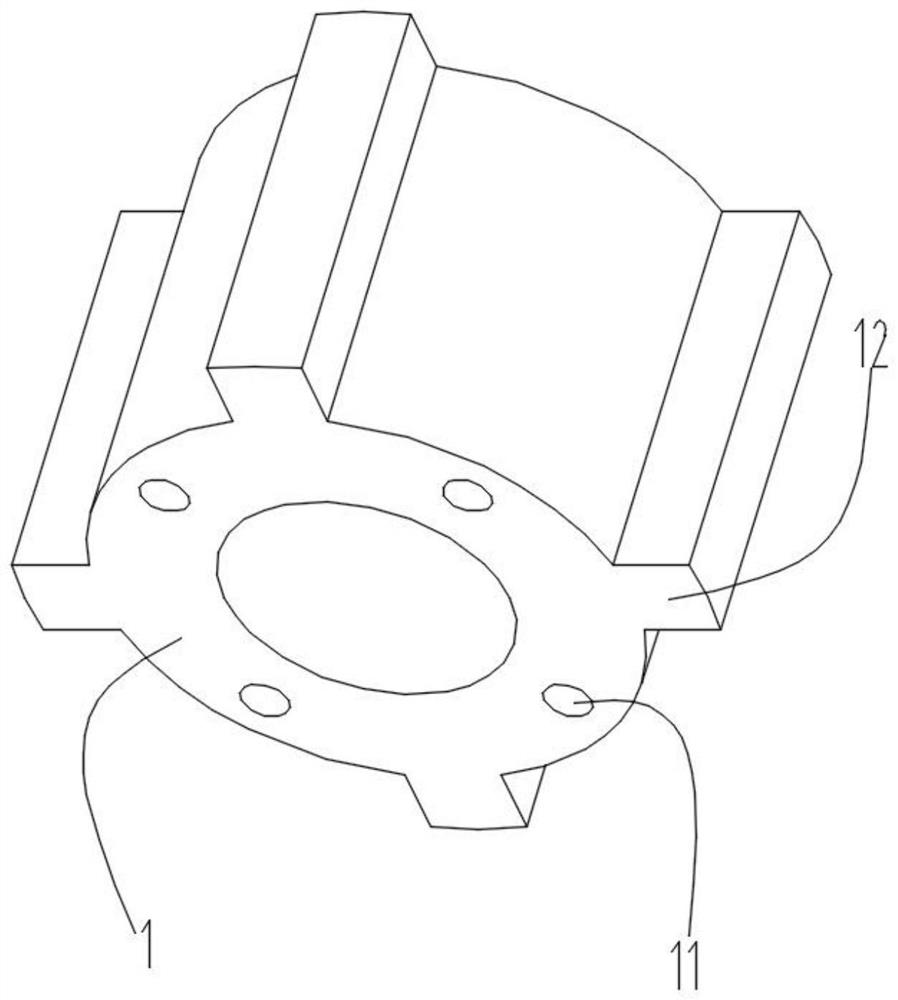

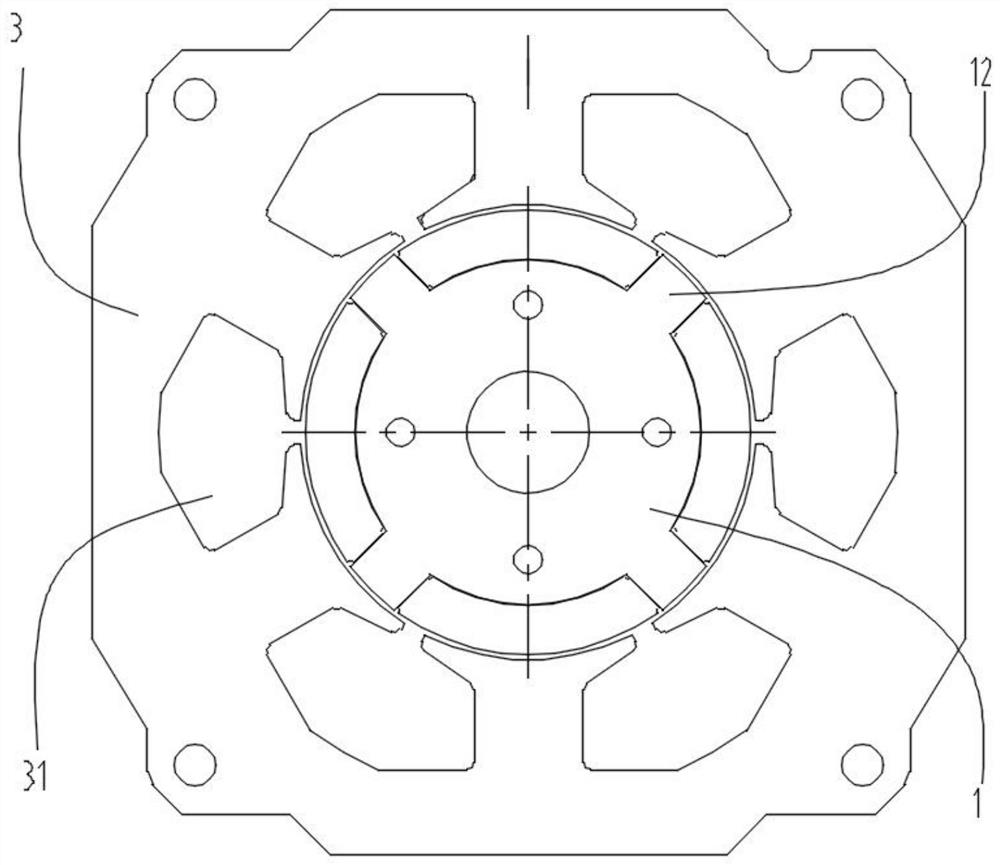

[0065] Such as Figure 1-6 As shown, the rotor of the motor according to Embodiment 1 of the present invention has an embedded rotor structure. By setting the relationship between the length of the extension part 12 and the thickness of the magnetic part 2, the existing motor torque ripple is large, the motor vibration and The problem of high noise; at the same time, it can solve the problem of large torque of motor cogging 31 and poor running stability, especially the problem of large speed fluctuation at low speed; while solving the problem of large motor torque ripple and large torque of cogging 31, it can reduce the motor Stray loss, which is beneficial to improve the efficiency of the motor.

[0066] The rotor of the motor in the embodiment of the present invention includes: a rotor core 1, a plurality of protrusions 12 and a plurality of magnetic parts 2, the rotor core 1 is evenly distributed with a plurality of protrusions 12 in the circumferential direction, and the p...

Embodiment 2

[0073] Such as Figure 1-3 , shown in 6 and 7, wherein the second embodiment shows an alternative embodiment, wherein the overall shape of the rotor (structure) is the same as that of the first embodiment Figure 1-3 The structure shown is the same except that the Image 6 The cross-sectional shape shown.

[0074] The rotor of the motor according to the second embodiment of the present invention is an embedded rotor structure. By setting the surface shape of the extension part 12, the problems of large torque ripple, motor vibration and noise of the existing motor can be solved; at the same time, the motor cogging can be solved. 31 has large torque and poor running stability, especially the problem of large speed fluctuation at low speed; while solving the problem of large motor torque ripple and cogging 31 torque, it can reduce the stray loss of the motor, which is conducive to improving the efficiency of the motor.

[0075] Such as Image 6 As shown, the rotor of the moto...

Embodiment 3

[0082] Such as Figure 8-13 As shown, the third embodiment shows an alternative embodiment, wherein the overall shape of the rotor structure is the same as that in the first embodiment Figure 1-3The structure shown is the same, the difference is that the protruding part 12 adopts Figure 8-9 The cross-sectional shape shown.

[0083] The rotor of the motor according to Embodiment 3 of the present invention is an embedded rotor structure. By setting grooves 13 on both sides of the extension part 12 and by setting the shape of the grooves 13, the existing motor torque ripple is large and the motor The problem of large vibration and noise; at the same time, it can solve the problem of large torque of motor cogging 31 and poor running stability, especially the problem of large speed fluctuation at low speed; while solving the problem of large motor torque ripple and large torque of cogging 31, it can Reducing the stray loss of the motor is conducive to improving the efficiency o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com