A transfer method for a double-station heat press machine

A heat transfer machine, double station technology, applied in transfer printing method, transfer printing, rotary printing machine and other directions, can solve the problems of low efficiency, difficult to effectively recover heat, etc., to reduce heat waste and improve energy utilization Efficiency, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

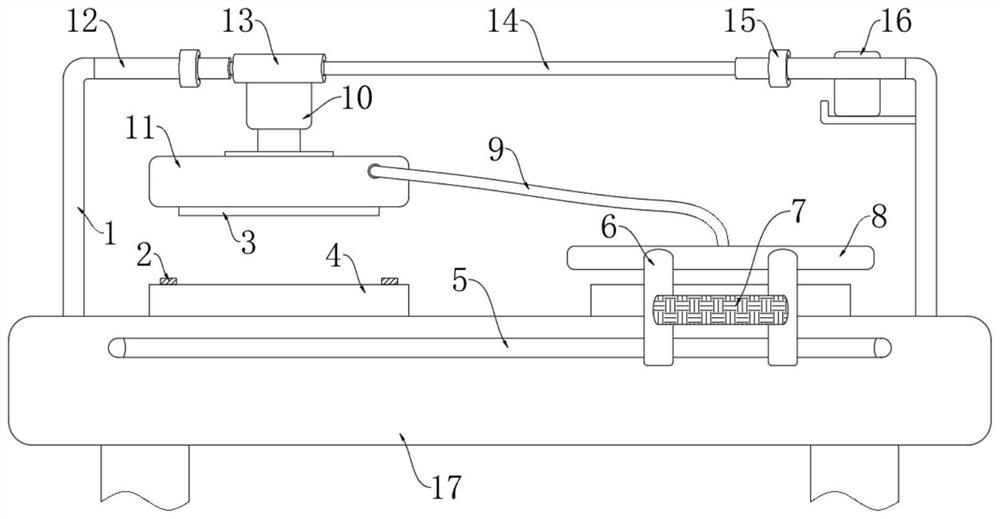

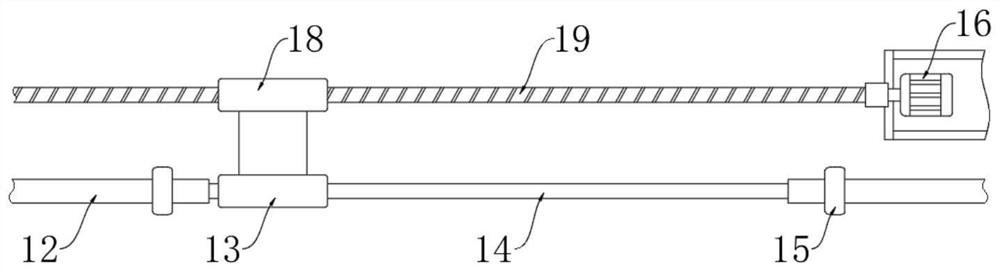

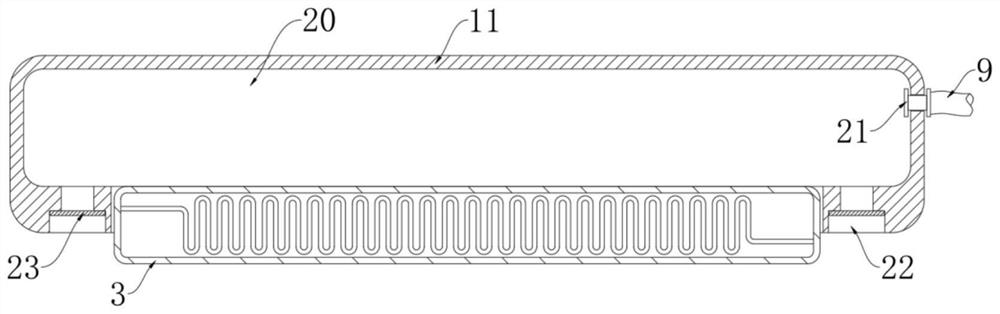

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0029] refer to Figure 1-4 , a double-station heat press machine transfer method, the specific method of use is as follows:

[0030] S1, start up and check: turn on the switch of the heat press machine, observe whether the heat conduction plate 3 is warming up, record the temperature rise speed and then close the heat press machine, and then drive the cylinder 10 and stepping motor 16 in sequence to check the operation of the equipment;

[0031] S2. Preheating: Turn on the switch of the heat press machine and keep it for 10-20 minutes;

[0032] S3. Calibration: adjust the position of the upper plate 11 so that it is directly above one station, while the flat releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com