Composite sectional material of frame, assembly low-rise building and demounting and mounting method

A prefabricated and framed technology, applied in residential construction, architecture, building construction, etc., can solve the problems of inconvenient maintenance and secondary use, time-consuming and labor-intensive installation process, and inability to quickly put into use, saving labor resources. , The construction speed is fast, and the rigidity is strengthened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

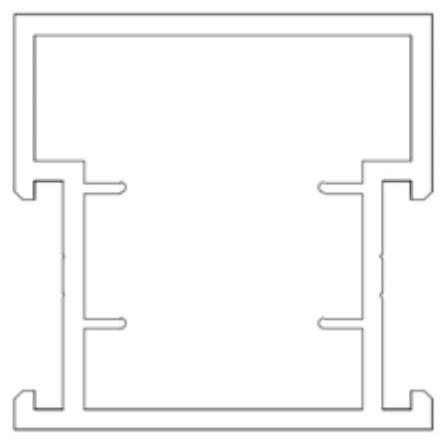

[0058] like figure 2 , image 3 , Figure 4 , Figure 5 Shown: a composition profile of a frame, including: keel, atrium.

[0059] The cross-section of the keel is: a hollow rectangle, and one adjacent two sides of the rectangle are partially recessed inward to form a C-shaped groove, and two protrusions are arranged on the back of the C-shaped groove, and the cross-section is symmetrical along its diagonal; The cross-section of the atrium is: a hollow rectangle, and a pair of sides of the rectangle are partially recessed inward to form a C-shaped groove, and two protrusions are respectively arranged on the back of the C-shaped groove; the cross-section is symmetrical along a central axis.

[0060] The keel, the atrium and the connecting strips are assembled into a slanted roof building frame. The connecting strips are integrally formed by the first side plate and the second side plate. The first side plate is provided with a protrusion, and the second side plate Grooves ...

Embodiment 2

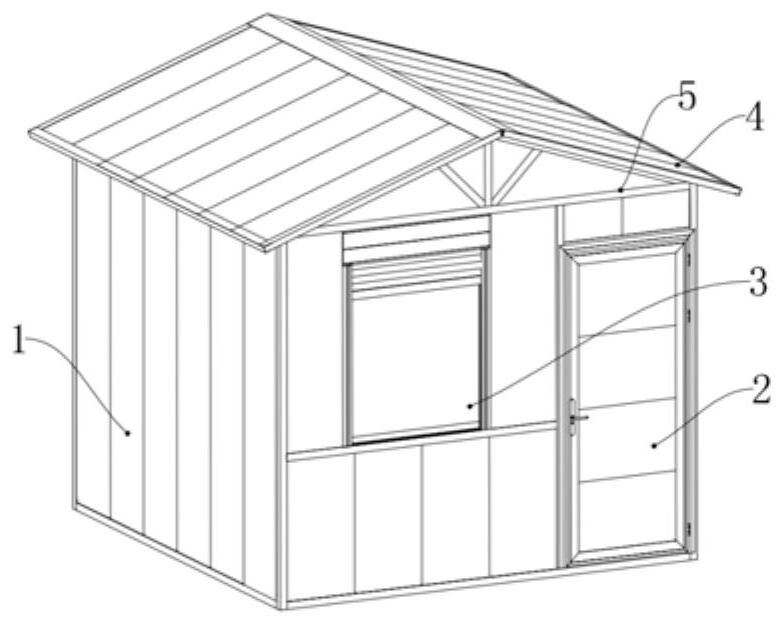

[0064] like figure 1 Shown: a low-rise building with a sloping roof frame assembly based on Embodiment 1, including wall panels 1, doors 2, windows 3, and roof 4; and the frame assembled from profiles described in Embodiment 1 5. The wall panel 1 is inlaid around the frame 5, the door 2 and the window 3 are installed on the facade of the frame 5, and the roof 4 is placed on the top of the frame 5. Described wallboard 1 is close to connecting bar and is fixed with screw as Image 6 The door 2 is installed in the door frame formed by the first door frame 505 and the second door frame 506, and the window 3 is installed between the middle beam 504 and the cross beam 503. like Figure 7-Figure 13 As shown: the window 3 includes a broken bridge window 31 and a shell; the shell includes an upper shell and guide rails 32, the guide rails 32 are arranged at both ends of the upper shell, the broken bridge window 31 is arranged between the guide rails 32, and the upper A curtain devic...

Embodiment 3

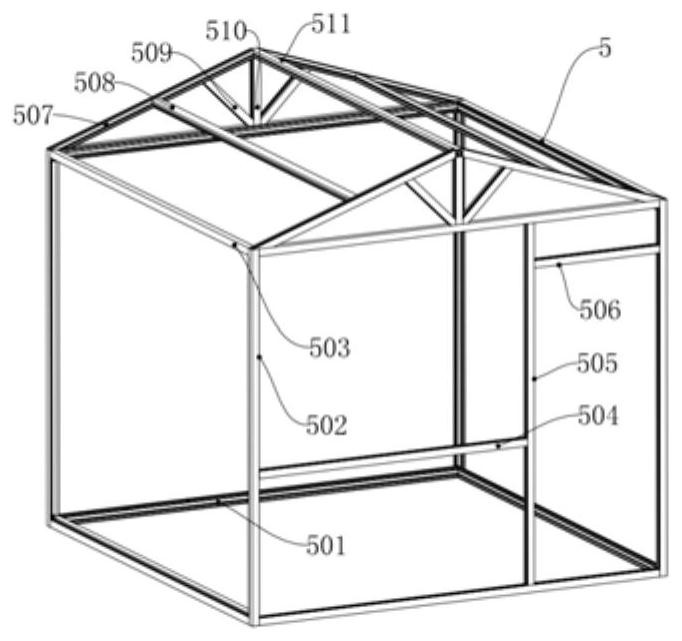

[0067] Based on the disassembly method of a kind of prefabricated low-rise building described in embodiment 1 and 2, the installation steps are:

[0068] Step 1: Connect and fix the ground beam 501 and the cross beam 503 to the lower end and upper end of the column 502 respectively through corner brackets to form a basic frame, and connect the first door frame 505, the second door frame 506, and the middle beam 504 at the same time;

[0069] Step 2: fix the spine 510, the diagonal brace 509, the first purlin 507, the second purlin 508, and the spine 511 above the foundation frame to form a roof frame;

[0070] Step 3: Install wall panel 1, roof 4, door 2, window 3;

[0071] The removal steps are: follow the installation steps in reverse to remove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com