An integrated control device and control method for crude oil transfer integration

An integrated control and crude oil technology, applied in chemical instruments and methods, feeding devices, control/regulating processes, etc., can solve problems such as low pump inlet pressure, high pump outlet pressure, and interlocking pump stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

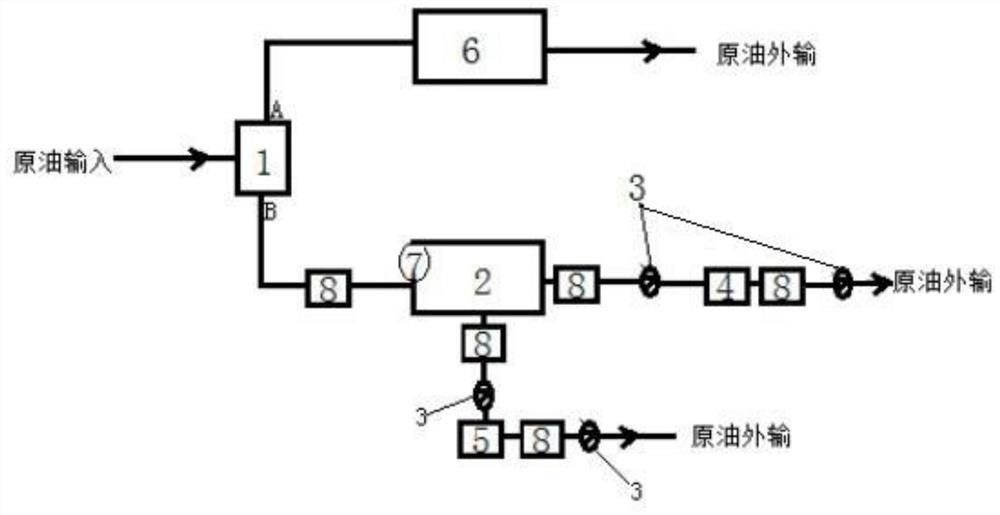

[0035] according to figure 1 The shown integrated integrated control device for transferring crude oil includes a three-way valve 1, an emergency oil tank 6 and a main oil pipeline; The input end of the oil pipeline is connected; the output end of the accident oil tank 6 and the output end of the main oil pipeline are respectively connected with the crude oil transportation pipeline; the main oil pipeline includes a separation buffer tank 2, an electric valve 3, a main oil pump 4, Standby oil delivery pump 5, liquid level measuring device and pressure measuring device; Described separation buffer tank 2 is respectively connected with liquid level measuring device, main oil delivery pump 4 and standby oil delivery pump 5; Described main oil delivery pump 4 and standby oil delivery pump The input end and output end of 5 are respectively connected with an electric valve 3 and a pressure measuring device; the input end of the separation buffer tank 2 is connected with a pressure ...

Embodiment 2

[0041] according to figure 1The shown integrated integrated control device for transferring crude oil differs from Embodiment 1 in that it also includes a control system; The oil pump 5 , the liquid level measuring device and the pressure measuring device are electrically connected to obtain the data information of the main oil delivery pipeline and send control signals to the electric valve 3 , the main oil delivery pump 4 and the standby oil delivery pump 5 .

[0042] Preferably, the three-way valve is an electric three-way valve 1 .

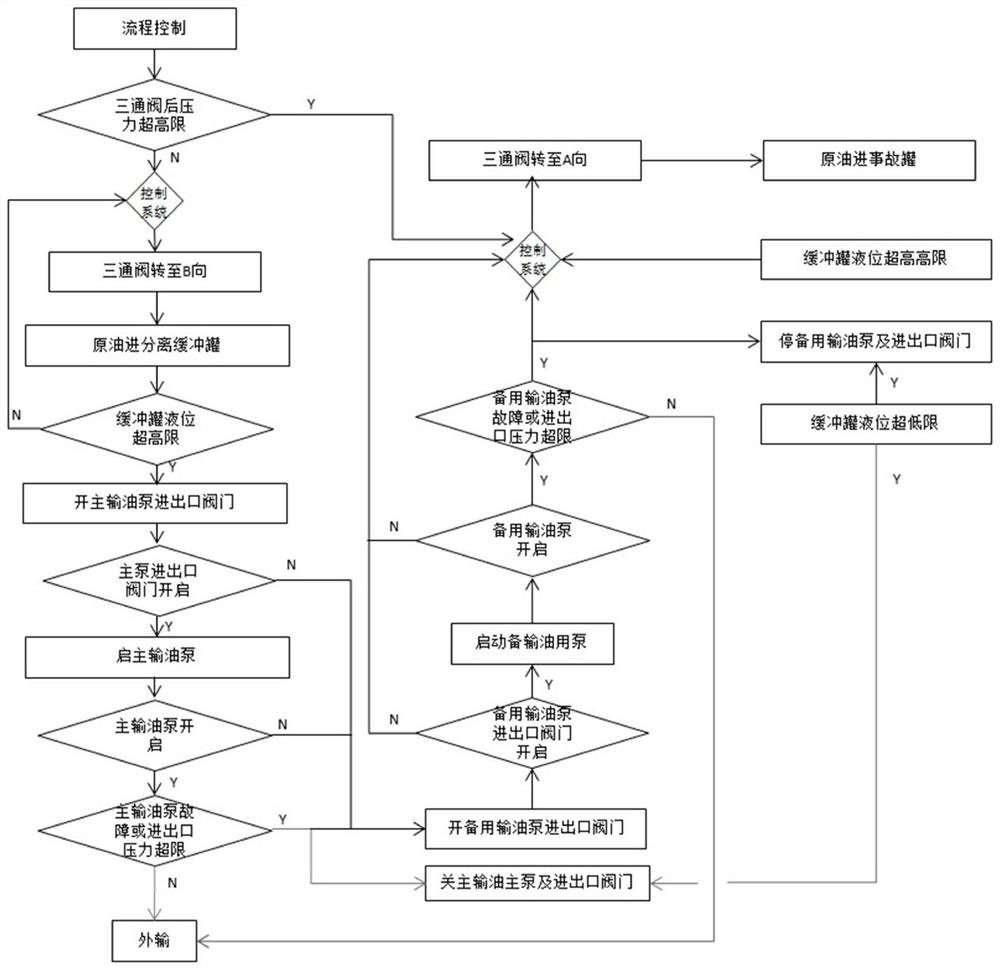

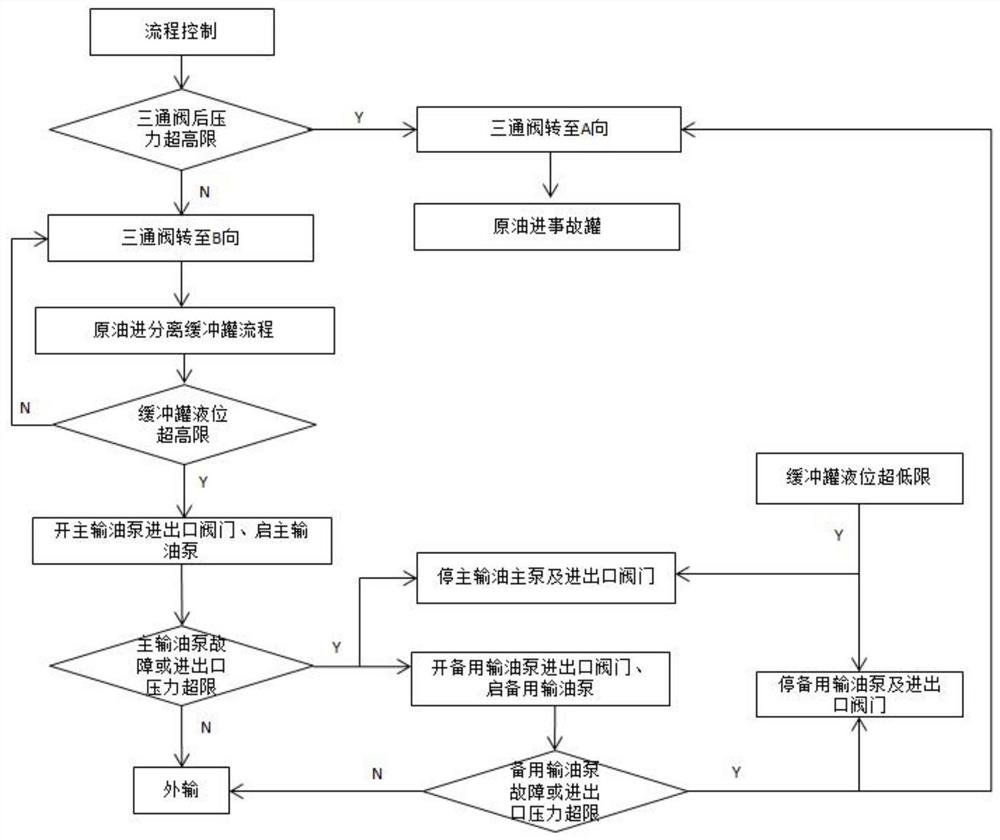

[0043] In actual use, the electric three-way valve 1 is turned to direction B, crude oil enters the separation buffer tank 2, and the liquid level measuring device and the pressure measuring device respectively transmit the liquid level and pressure signals of the separation buffer tank 2 to the control system; when the separation buffer When the liquid level of tank 2 exceeds the preset upper limit, the control system sends an instruction t...

Embodiment 3

[0047] according to figure 1 The shown integrated control device for transferring crude oil is different from the second embodiment in that the liquid level measuring device uses a liquid level transmitter 7 .

[0048] Preferably, the pressure measuring device adopts a pressure transmitter 8 .

[0049] In actual use, the liquid level measuring device and the pressure measuring device adopt the technical solution, which not only makes the obtained pressure or liquid level information more accurate, but also facilitates automatic control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com