Novel short MPO connector

A connector and a new type of technology, applied in the field of new short MPO connectors, can solve the problems of small applicable environment, unfavorable promotion and application, poor compatibility, etc., and achieve the effect of strong matching effect, reduced space occupancy, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

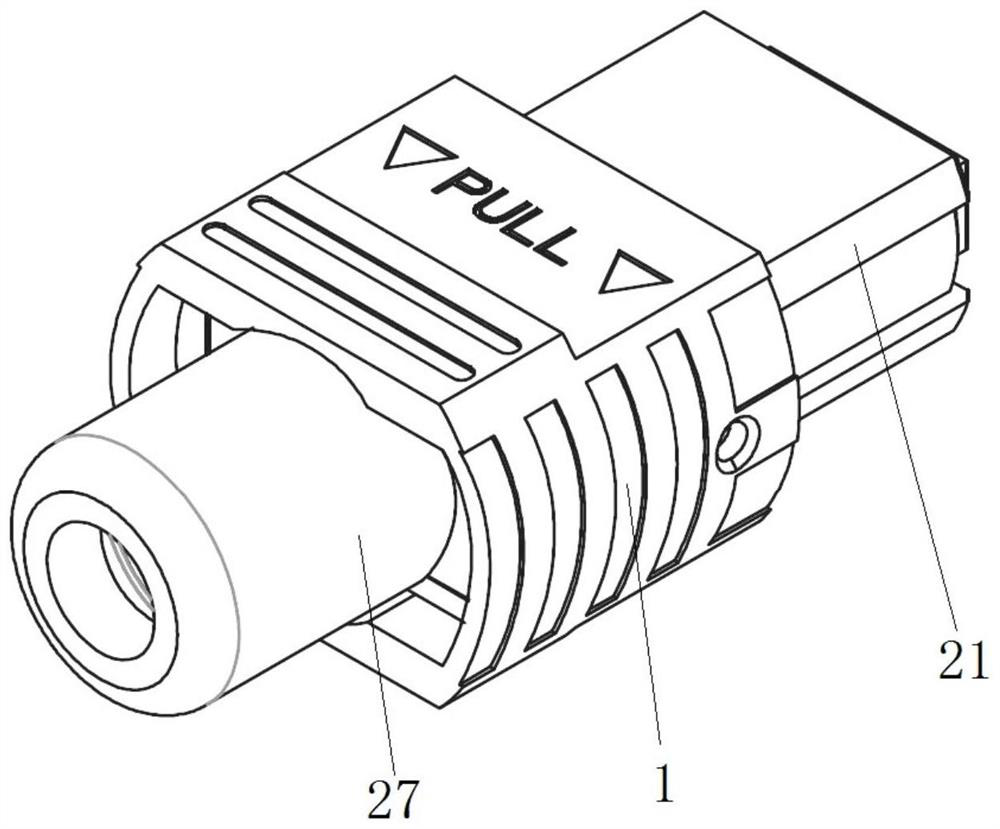

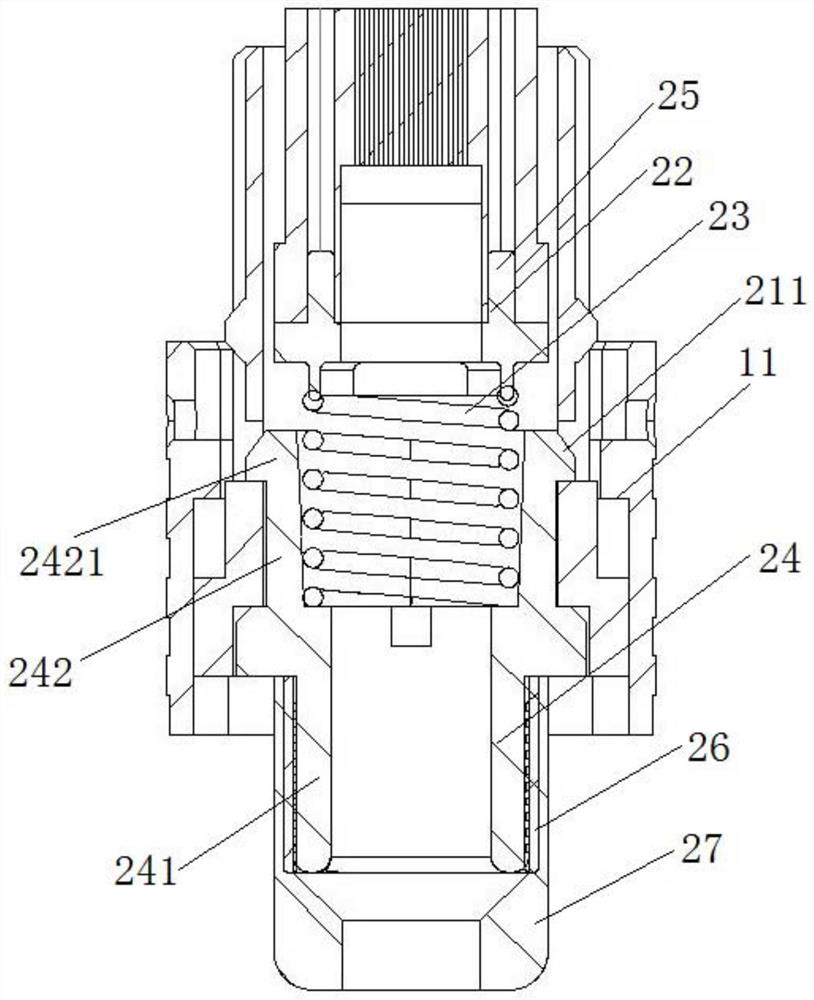

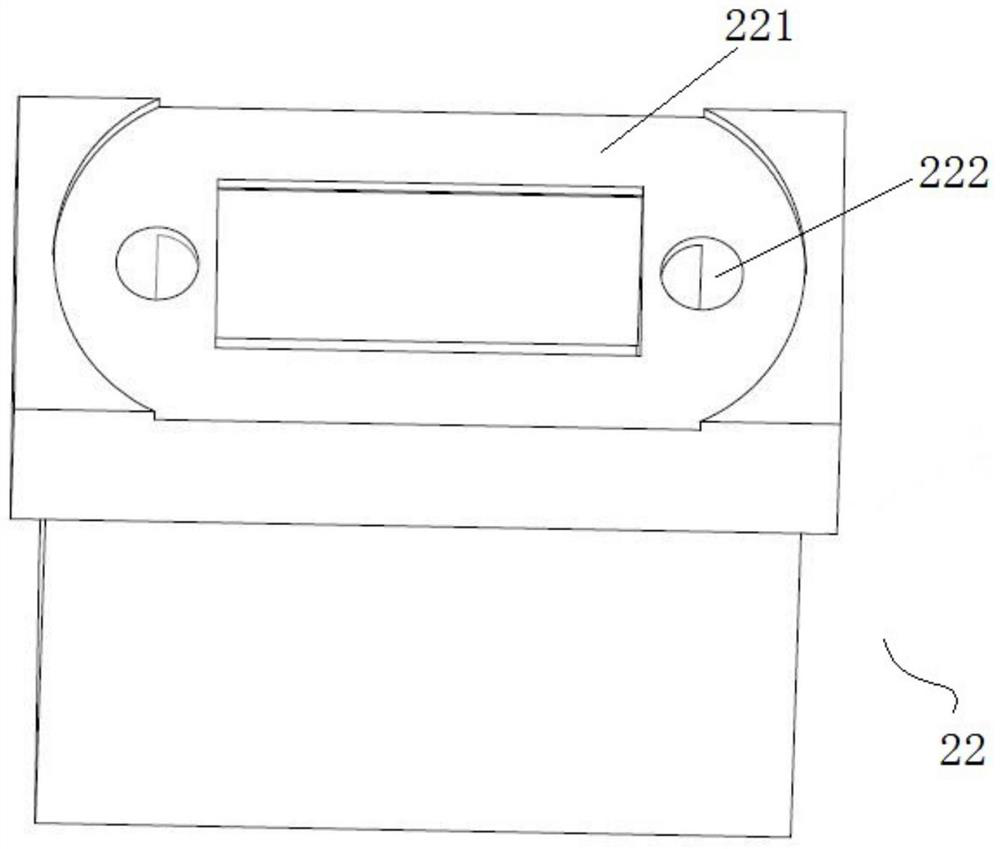

[0036] Such as Figure 1-Figure 5 As shown, a new type of short MPO connector is provided, which includes an outer shell and a connector body. The outer shell can be axially movably sleeved on the connector body. The connector body includes an inner shell, and the inner shell is sequentially provided with MT Ferrule, push spring, socket, press buckle and net tail; the tail of MPO connector is fixed on the cable by press buckle and net tail; the bottom of MT ferrule is provided with a concave table that matches the shape of the push spring , There are counterbore holes on both sides of the concave table, guide pins are pierced in the counterbore holes, and guide pin steps matching the counterbore are provided at the bottom of the guide pins, and the push spring presses the bottom of the guide pins; the inner shell and An unlocking spring accommodating cavity is arranged between the outer shells; an unlocking spring is fixedly arranged in the unlocking spring accommodating cavit...

Embodiment 2

[0044] This example is similar to Embodiment 1, the difference is that, as Figure 6 As shown, in this example, two unlocking grooves II are provided on the front and rear sides of the inner wall of the inner shell and the inner wall of the outer shell, forming four unlocking spring accommodation chambers, and the four unlocking spring accommodation chambers are respectively provided with unlocking springs. The unlocking spring is a linear cylindrical spring; the length of the unlocking groove II is L3, and the interval of L3 is 3mm≤L3≤5mm. In this example, the length L3 of the unlocking groove II is 4 mm. Moving the unlocking spring to the front and back of the inner casing can increase the thickness of the front and rear side walls of the inner casing, and prevent the inner casing from cracking when the socket is pulled sideways.

[0045] The number of linear cylindrical springs is 4, which are respectively arranged on both sides of the front side and the rear side of the i...

Embodiment 3

[0047] This example is similar to Embodiment 1, the difference is that, as Figure 7 and Figure 8 As shown, the front and rear surfaces of the tail end of the inner housing are provided with a limit key two, the limit key two is a tail end flange, and an unlocking spring accommodation chamber is formed between the limit key two and the tailstock of the inner housing, and the unlocking spring accommodates The cavity is fixed with an unlocking spring, and the unlocking spring is a spring in the shape of a dovetail clip; the lateral thickness of the limit key 2 is L4, and the interval of L4 is 0.3mm≤L4≤0.6mm. In this example, the transverse thickness L4 of the limit key 2 is 0.4mm, and the height L7 of the buckle is 4mm.

[0048] Specifically, in the vertical direction, the tail end flange of the inner casing and the tailstock of the inner casing form a slot space, and the spring can be directly snapped into the slot to provide a fixed support for the unlocking spring. Yes, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com