A finned microchannel design method for 3d-sip radio frequency microsystem

A design method and micro-system technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as low design efficiency, shortening service life, hindering the improvement of chip liquid cooling device performance, etc., to reduce design costs , the effect of improving reliability and high design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

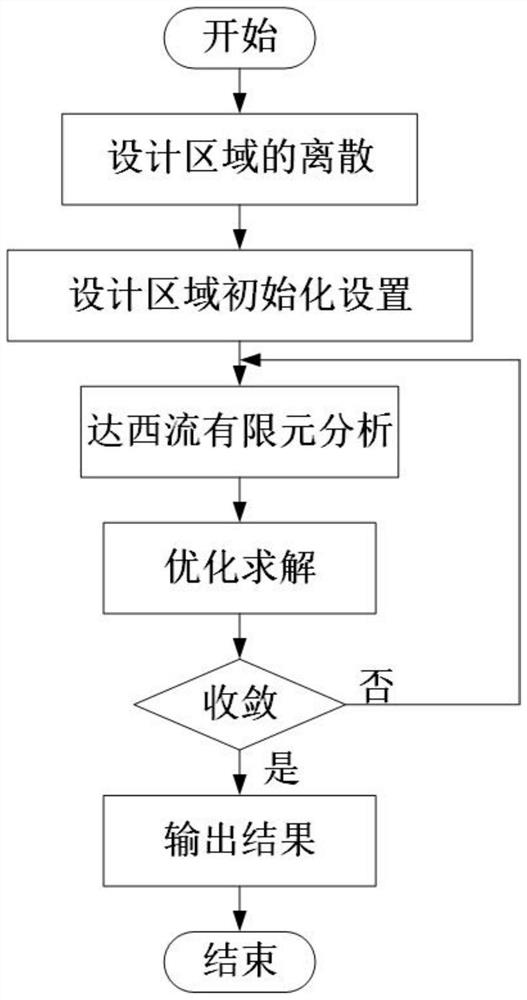

[0049] refer to figure 1 , a 3D-SIP radio frequency microsystem design method for finned microfluidic channels, comprising the following steps:

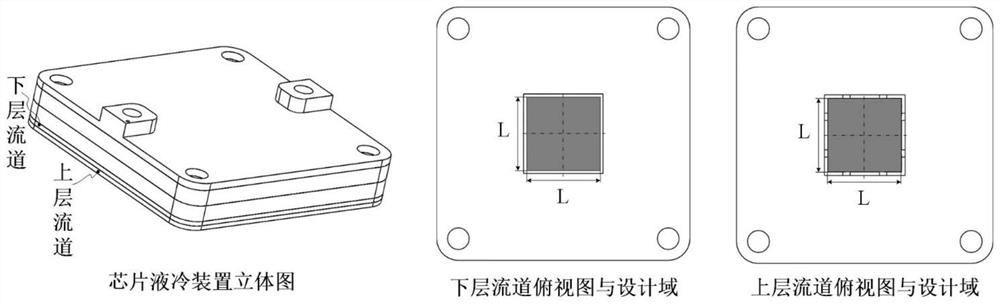

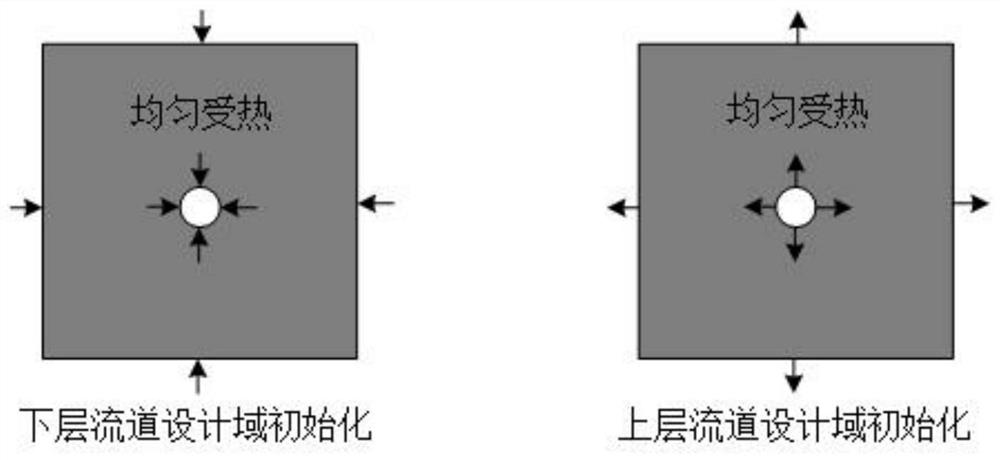

[0050] 1) Discretization of the design area: such as figure 2As shown, the design area, that is, the flow channel area of the chip liquid cooling device is composed of upper and lower parts, which are divided into the upper flow channel and the lower flow channel according to the order in which the coolant flows. The actual size of the heat dissipation area to be designed is L (mm )×L(mm), according to the symmetric characteristics of the flow channel area of the chip liquid cooling device, only a quarter of the flow channel area is designed, and the design result of the complete flow channel area is obtained through the symmetrical relationship; The actual parameters of the road area entity d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com