Electric power inspection equipment

A power inspection and equipment technology, applied in the direction of overhead lines/cable equipment, current collectors, electric vehicles, etc., can solve the problems of not getting timely feedback of information, difficult observation of monitoring screens, equipment failures, etc., to avoid unsightly shooting pictures Clear, avoid frequent shaking of the car body, and improve the effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

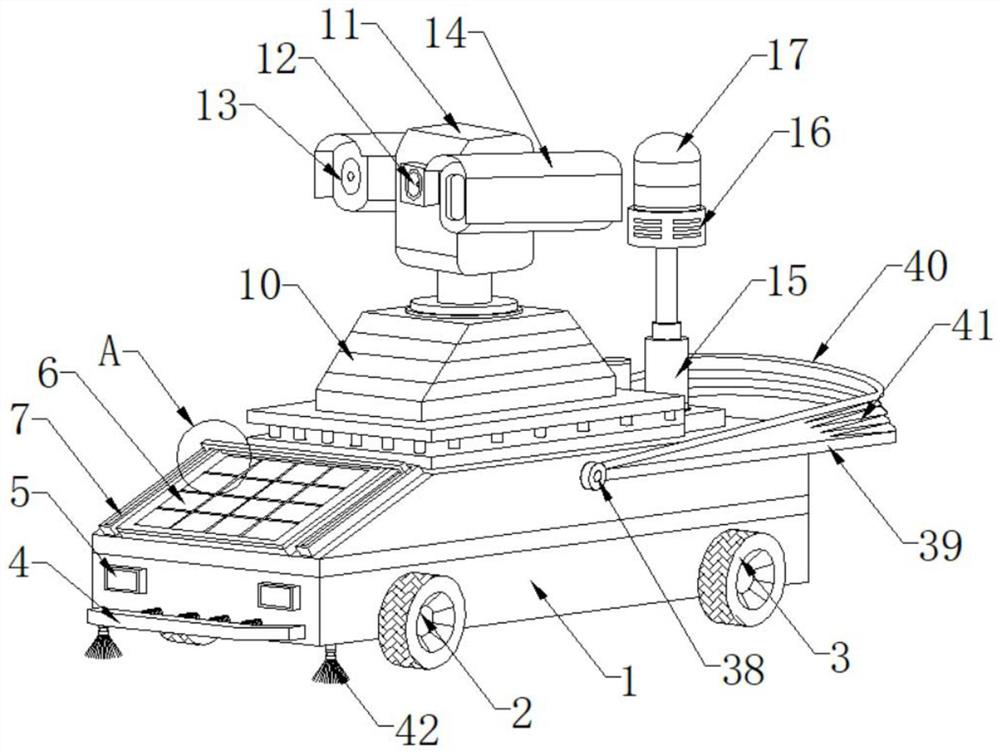

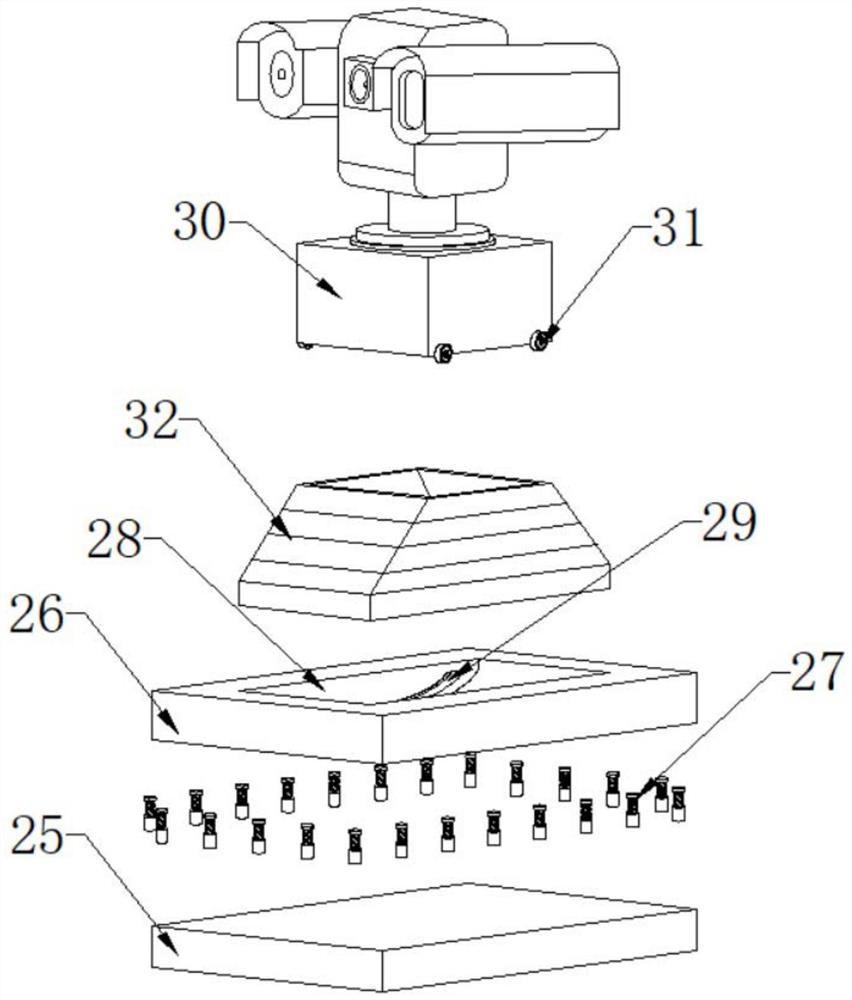

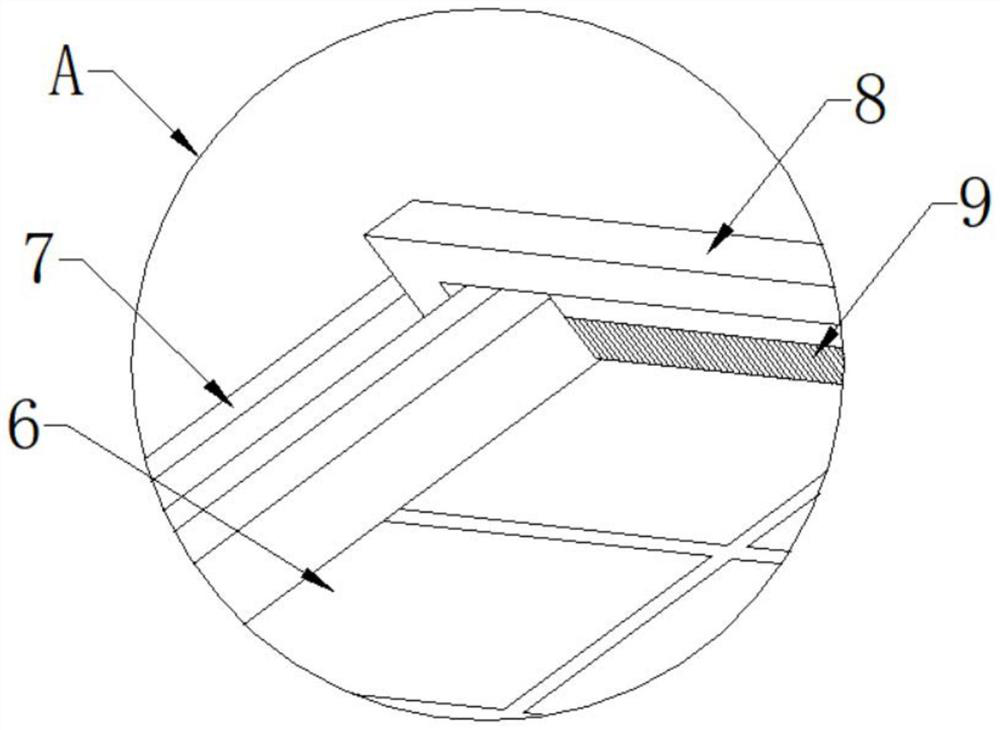

[0033] Such as Figure 1-4 As shown, the present invention provides an electric power inspection equipment, including a vehicle body 1, a steering wheel 2 is installed on the front side of the chassis of the vehicle body 1, a driving wheel 3 is installed on the rear side of the chassis of the vehicle body 1, and the front side of the vehicle body 1 A collision bar 4 is installed on the surface. The top two sides of the collision bar 4 are equipped with infrared ranging radar 5. The front top of the car body 1 is an inclined platform surface, and solar photovoltaic panels 6 are installed on both sides of the solar photovoltaic panels 6 Slide rails 7 are installed side by side, a beam 8 is connected between the slide rails 7, and a brush 9 is provided on the bottom surface of the beam 8, and the brush 9 is against the surface of the solar photovoltaic panel 6, and one side of the solar photovoltaic panel 6 is provided There is a shock absorber 10, the top surface of the shock abso...

Embodiment 2

[0044] Such as Figure 3-6 As shown, the present invention provides an electric power inspection equipment, including a vehicle body 1, a steering wheel 2 is installed on the front side of the chassis of the vehicle body 1, a driving wheel 3 is installed on the rear side of the chassis of the vehicle body 1, and the front side of the vehicle body 1 A collision bar 4 is installed on the surface. The top two sides of the collision bar 4 are equipped with infrared ranging radar 5. The front top of the car body 1 is an inclined platform surface, and solar photovoltaic panels 6 are installed on both sides of the solar photovoltaic panels 6 The slide rails 7 are installed side by side, a beam 8 is connected between the slide rails 7, and the bottom surface of the beam 8 is provided with a brush 9, and the brush 9 is against the surface of the solar photovoltaic panel 6, and one side of the solar photovoltaic panel 6 is provided There is a shock absorber 10, the top surface of the sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com