Self-adaptive leading edge blanking circuit based on high-precision load current detection technology

A technology of load current detection and leading edge blanking, which is applied in the direction of high-efficiency power electronic conversion, electrical components, and adjustment of electrical variables, can solve the problem of inaccurate sampling of knee point voltage, so as to avoid wrong sampling of knee point voltage and reduce light load Power consumption, the effect of avoiding false sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the public have a deeper understanding of the present invention, a specific embodiment of the present invention will be described and analyzed in detail below in conjunction with the accompanying drawings, and the working principle and practicability of the present invention will be introduced, but the present invention is not limited to this specific embodiment . The present invention covers any modifications, alternative methods and schemes within the spirit and scope of the present invention.

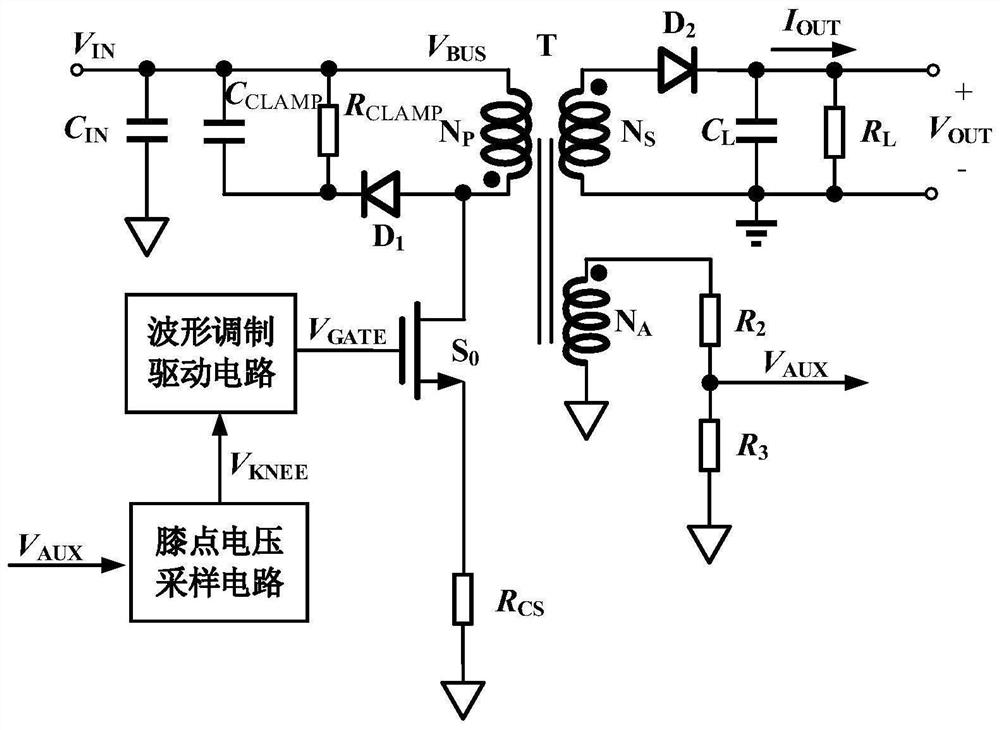

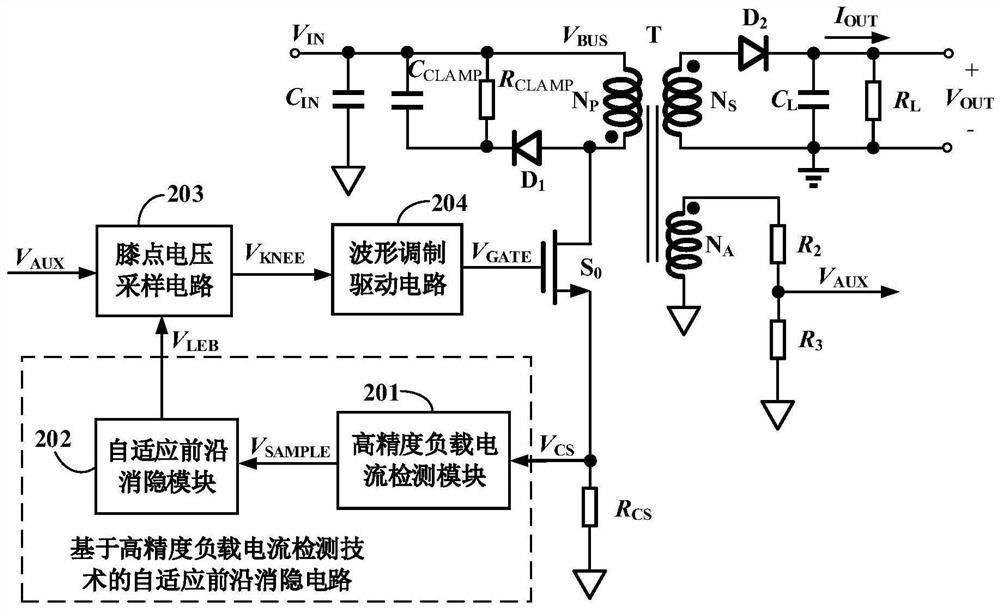

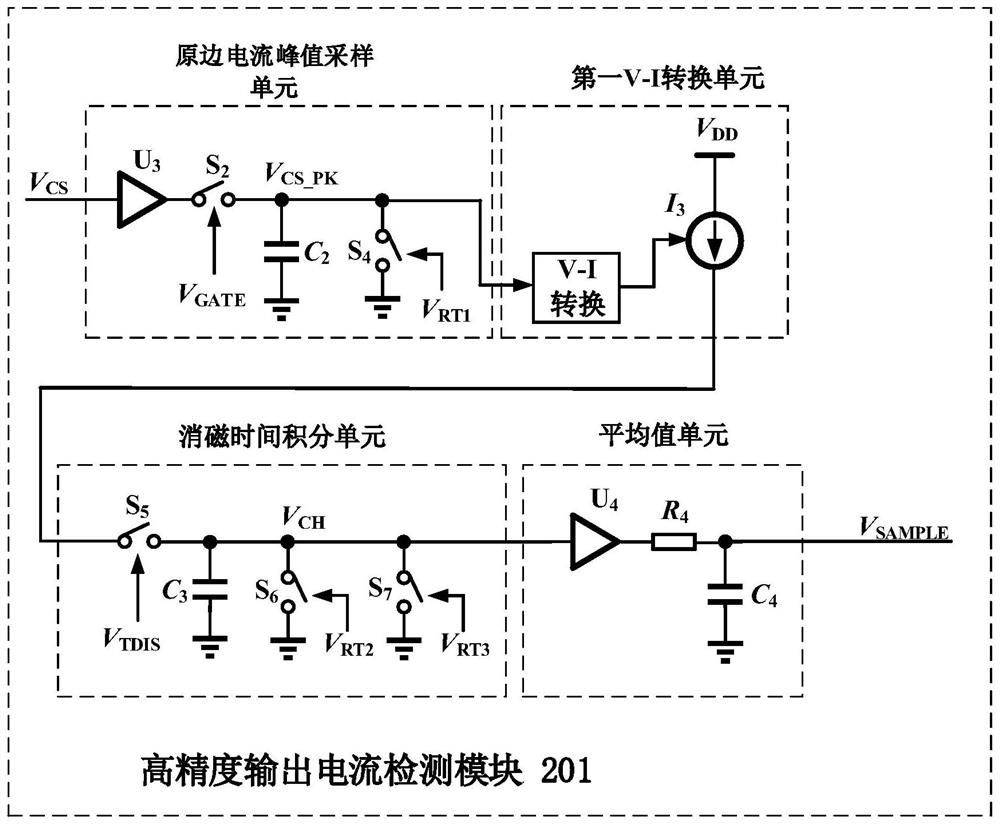

[0035] Such as figure 2 As shown, an adaptive leading edge blanking circuit based on high-precision load current detection technology proposed by the present invention includes a high-precision load current detection module 201 and an adaptive leading edge blanking time setting module 202 . Among them, the high-precision load current detection module 201 is used for the primary side switch tube S of the primary side feedback flyback converter 0 The source s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com