Electric valve control device and electric valve device including the electric valve control device

A control device and electric valve technology, applied in the field of electric valve control devices and electric valve devices, can solve the problems of electric valve life shortening, synchronization deviation, out-of-step, etc., and achieve the effect of shortening life and preventing the reduction of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

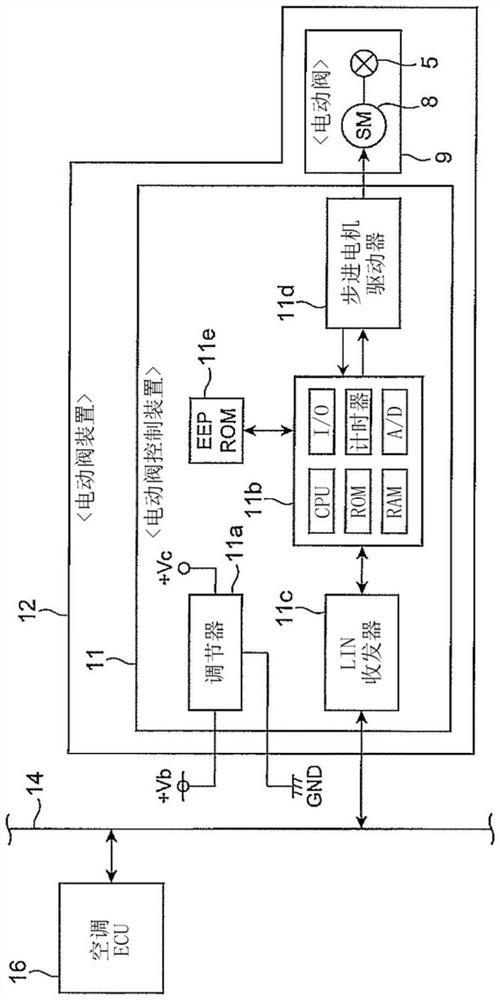

[0033] [Structure of Electric Valve Control Device and Electric Valve Device Equipped with the Electric Valve Control Device]

[0034] figure 1 It is a system block diagram of a first embodiment of an electric valve control device and an electric valve device including the electric valve control device according to the present invention. In addition, in the following description, the case where the electric valve control device of the present invention is applied to an expansion valve of a refrigeration cycle system used in an automobile air conditioner will be described as an example.

[0035] In the electric valve device 12 of the illustrated embodiment, the electric valve 9 and the electric valve control device 11 are connected by lead wires, etc., and are not in separate positions but are assembled into one body. The electric valve 9 is composed of an expansion valve 5 and a stepping motor 8. The expansion valve 5 has a spool (not shown) that controls the flow rate of the...

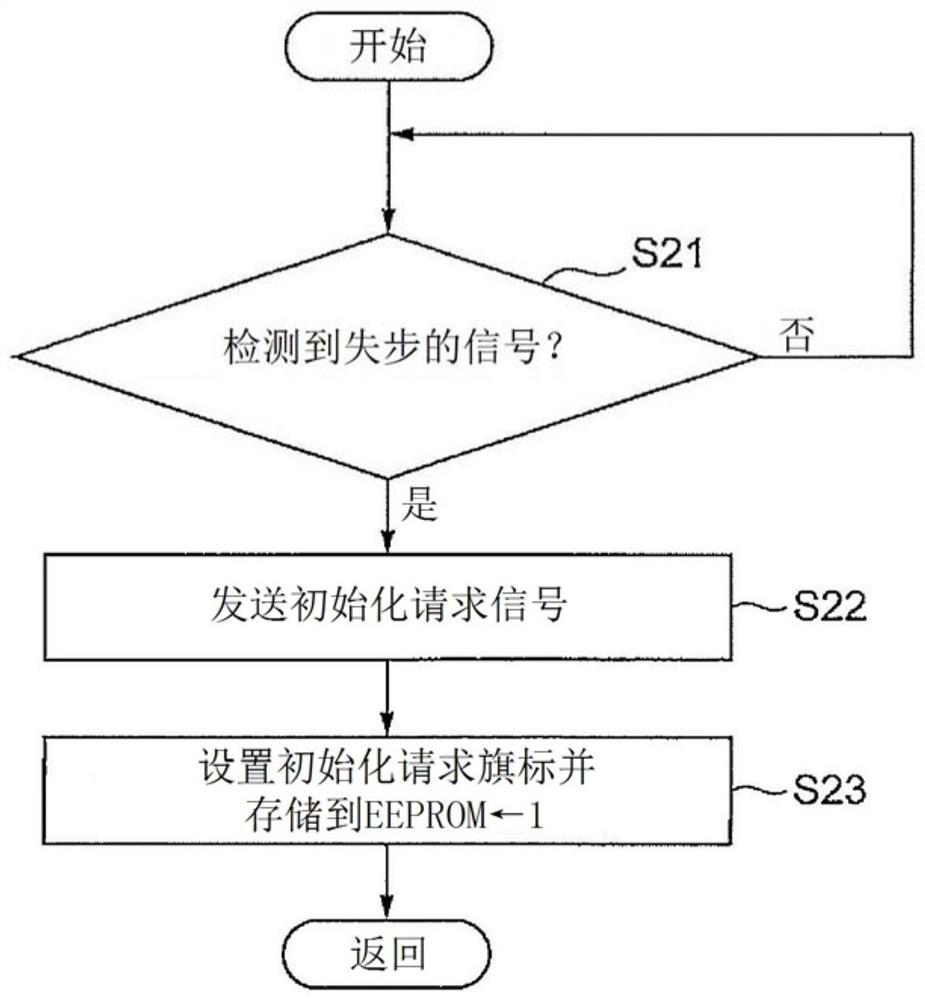

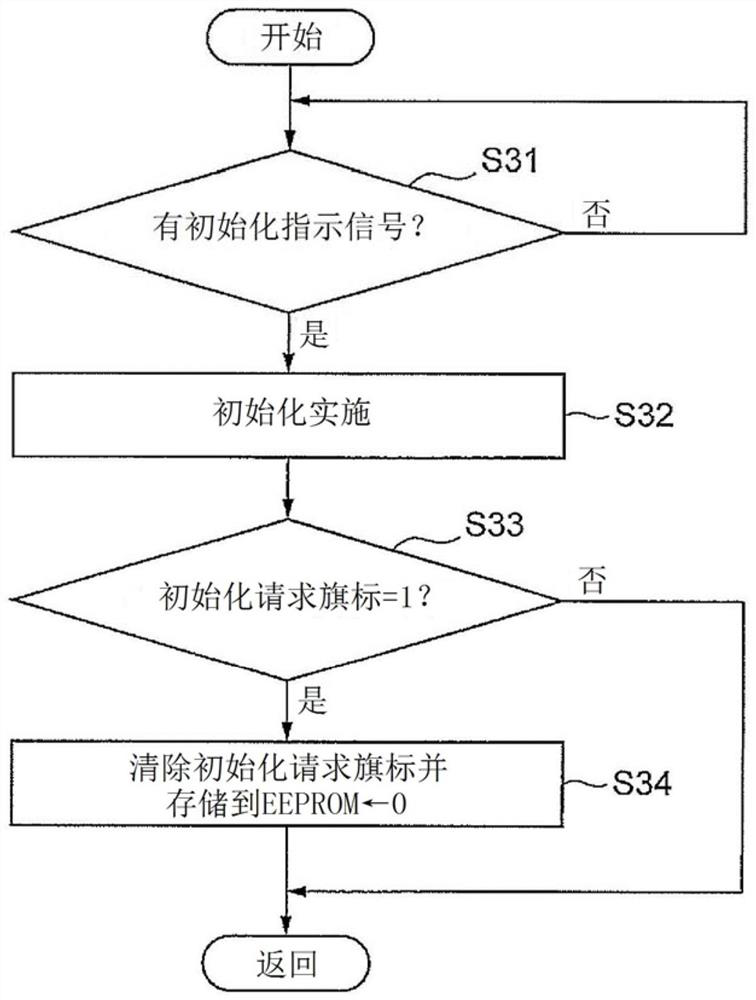

no. 2 approach

[0064] Figure 4 It is a system block diagram of a second embodiment of an electric valve control device and an electric valve device including the electric valve control device according to the present invention. The structure of the electric valve control device of the second embodiment and the electric valve device including the electric valve control device is substantially the same as that of the electric valve control device 11 and the electric valve device 12 including the electric valve control device 11 of the first embodiment described above. Similarly, the difference from the first embodiment described above is only the configuration and processing for detecting out-of-synchronization. Therefore, the same reference numerals are assigned to the same configurations as those of the above-mentioned first embodiment, and detailed description thereof will be omitted, and the above-mentioned differences will be described below.

[0065] That is, if Figure 4As shown, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com