Hole drilling structure, device and equipment for tobacco

A technology of tobacco and equipment, applied in the field of tobacco planting, can solve the problems of providing a better transplanting environment for well pits, damage to the side wall structure of well pits, and low automation of hole punching, so as to improve the level of mechanization and planting scale, and reduce a lot of labor Dependence, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

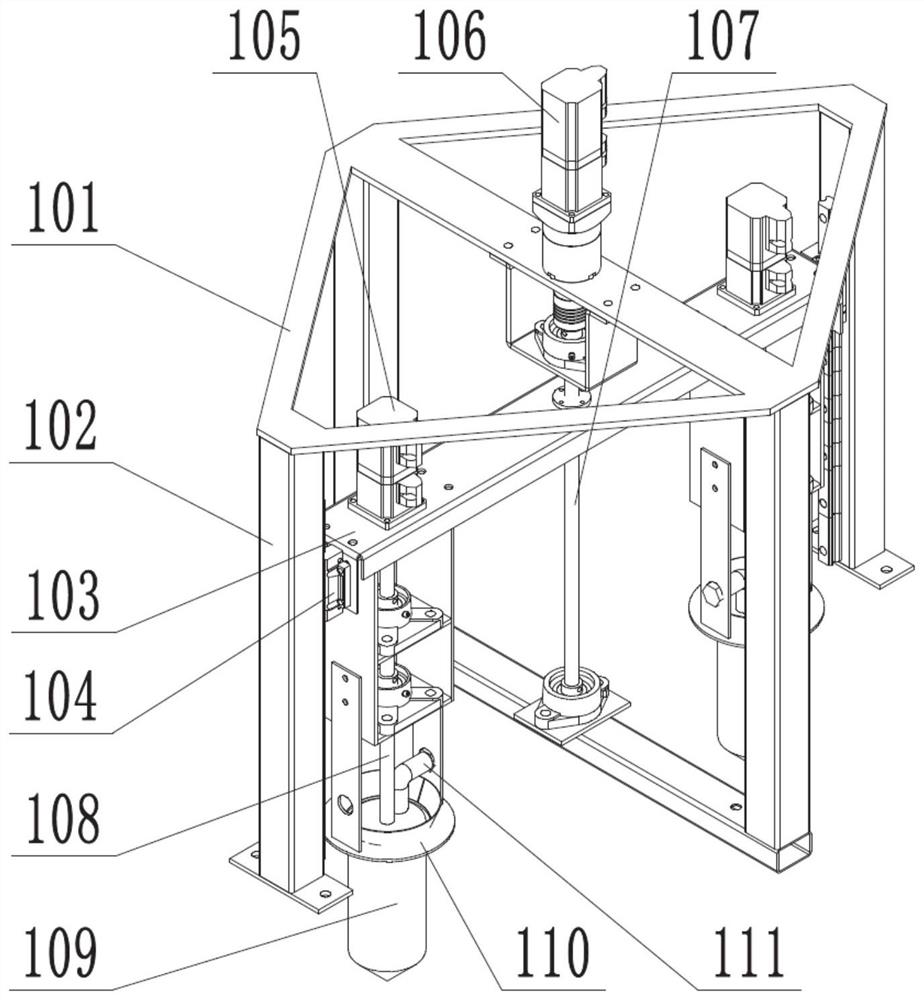

[0036] In a typical implementation of the present disclosure, such as Figure 1-Figure 3 As shown, a tobacco hole punching structure is proposed.

[0037] It mainly includes a drill bit and a water supply mechanism. The drill bit is a cylindrical structure with a tapered end. The water supply mechanism is set opposite to the drill bit. Soil body shaping; the head of the hole drilling bit adopts a conical structure, which is convenient for drilling holes downwards, and the middle part is a cylindrical wall, which is convenient for forming the wall of the well cellar;

[0038] The drill bit is rotatably mounted on the drill bit bracket, and the end of the drill bit away from the taper is equipped with a driving mechanism for driving the drill bit to rotate around the axis;

[0039] In this example, if figure 2 As shown, the punching drive mechanism is a punching motor 105, which is installed on the drill bit bracket. Two bearings are fitted on the drill bit through two bearin...

Embodiment 2

[0047] In another typical implementation of the present disclosure, such as Figure 1-Figure 3 As shown, a tobacco hole punching device is proposed.

[0048] It mainly includes a support seat and the tobacco hole punching structure as described in Embodiment 1. The tobacco hole punching structure is installed on the support seat through a linear motion pair, and the lifting drive mechanism cooperates with the linear motion pair to drive the drill bit to reciprocate along the drill bit axis;

[0049] In this embodiment, the linear motion pair is a lead screw slider mechanism composed of a lead screw and a screw nut, and the lift drive mechanism is a lift motor 106, the output end of which is connected to a lead screw 107 to drive the lead screw to rotate, Thereby adjusting the position of the tobacco hole structure.

[0050] The supporting seat is equipped with at least one tobacco hole punching structure. When there are multiple tobacco hole punching structures, the tobacco h...

Embodiment 3

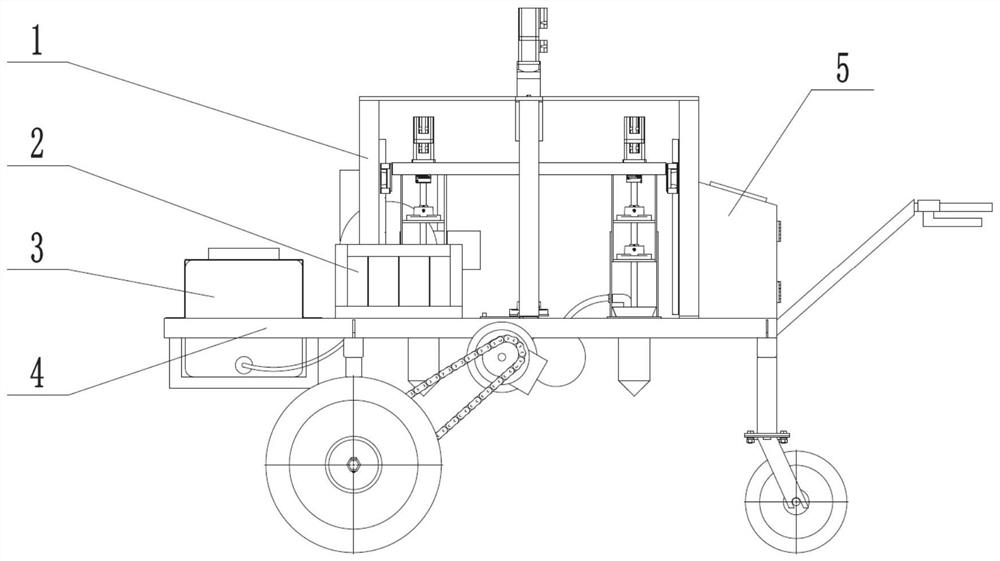

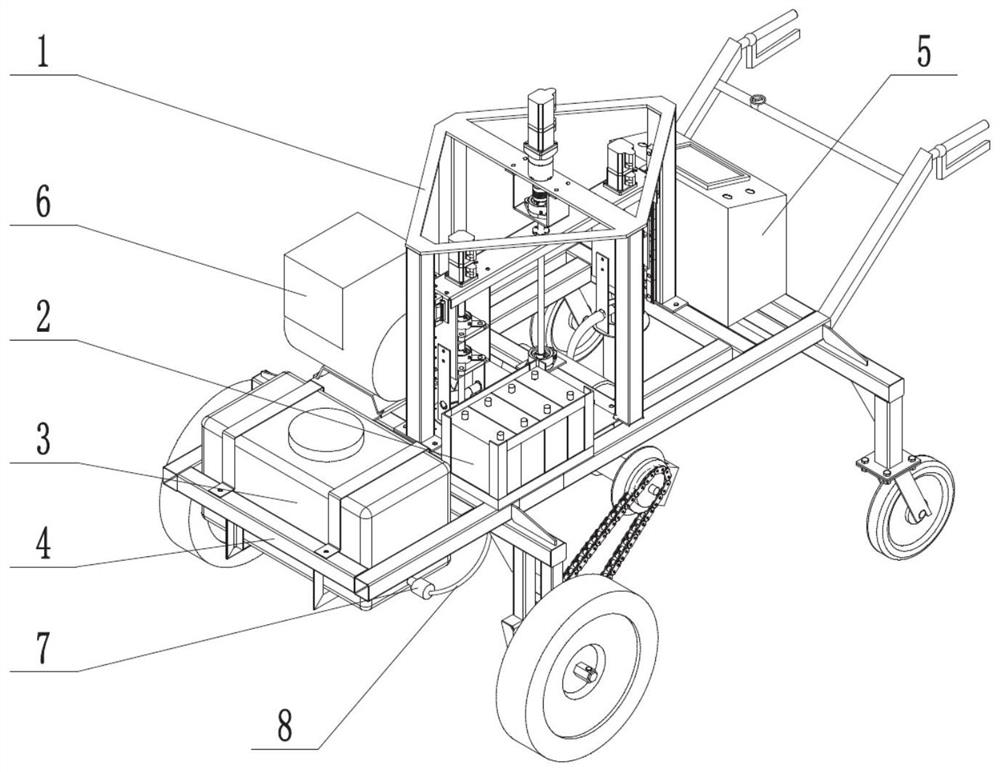

[0060] In yet another typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a tobacco hole punching device is proposed.

[0061] Self-propelled along the gap between the ridges in the field, to realize the drilling operation of the well cellar on the tobacco planting ridge, mainly including the walking mechanism 4, the hole punching mechanism 1, the control box 5, the water tank 3, the battery 2 and the generator 6;

[0062] The generator is a gasoline generator, which provides electric energy for the whole machine, and the battery is connected in parallel to supply power to the whole machine, driving the electric traveling mechanism to realize gap walking;

[0063] Under the coordination of the control box, the acupoint-punching mechanism installed on the upper part of the traveling mechanism completes the acupoint-punching work during the gap between the traveling mechanism, and at the same time, the water tank injects water into the acupoint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com