Industrial harmful waste gas treatment device based on VOC biological method

A waste gas treatment device and biological method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as inability to effectively deal with waste gas at intake flow rate, and achieve the effect of increasing mass transfer time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

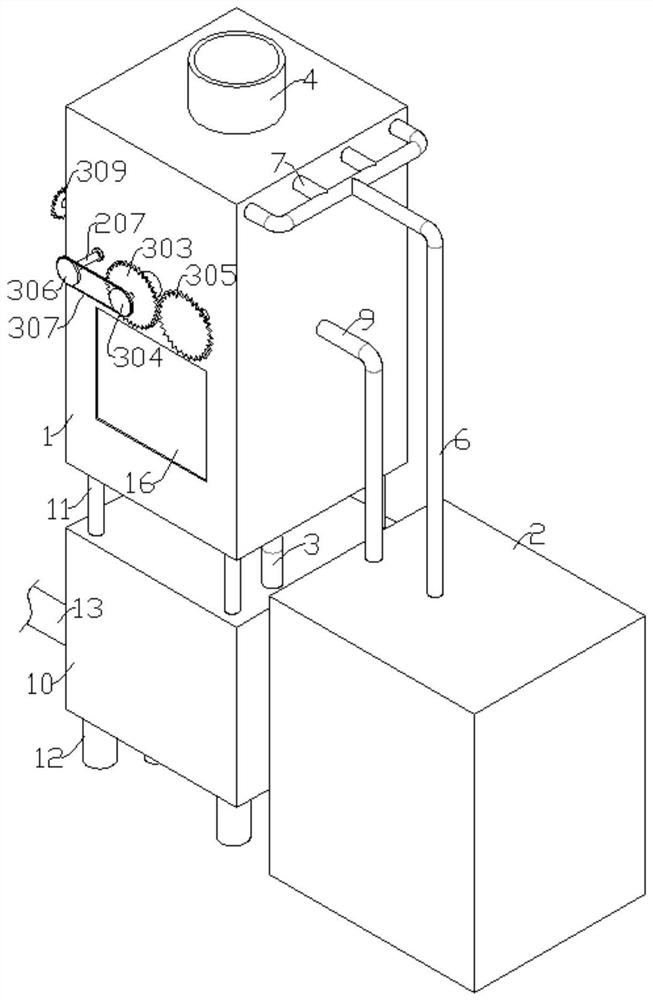

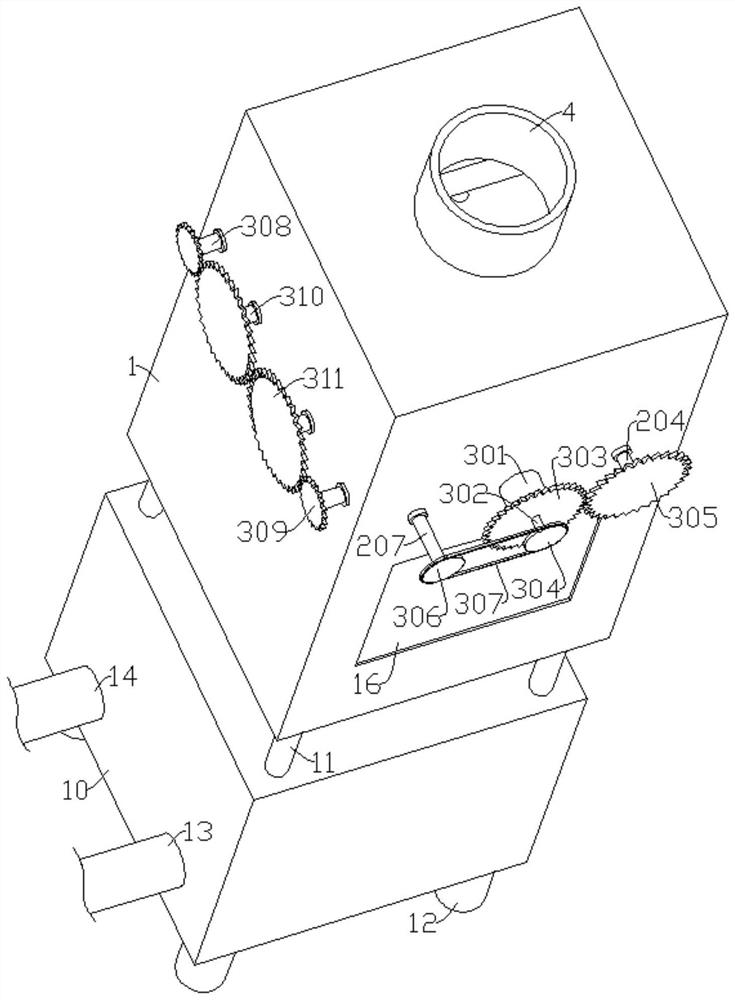

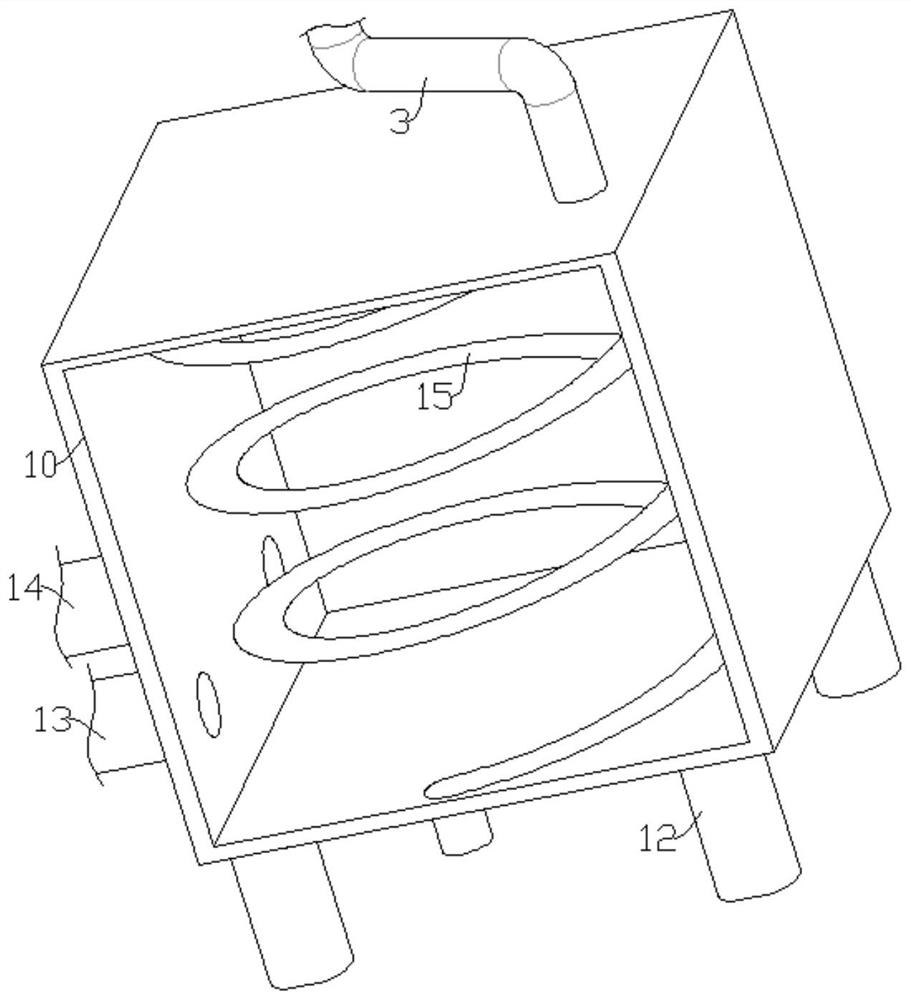

Embodiment 1

[0022] refer to Figure 1-6, an industrial hazardous waste gas treatment device based on VOCs biological method, including a treatment chamber 1 and an activated sludge chamber 2, the bottom of the treatment chamber 1 is connected with an air inlet pipe 3, the top of the treatment chamber 1 is connected with an outlet pipe 4, and the upper end of the treatment chamber 1 A porous packing layer 5 is provided, a liquid inlet pipe 6 is connected between the treatment chamber 1 and the activated sludge chamber 2, and one end of the liquid inlet pipe 6 is connected with a plurality of liquid inlet manifolds 7, and the liquid inlet manifolds 7 are connected to the treatment chamber 1 The bottom of the liquid inlet manifold 7 located in the treatment chamber 1 is connected with a plurality of evenly distributed nozzles 8, and the nozzles 8 are all located above the porous packing layer 5, and there is a circulation between the treatment chamber 1 and the activated sludge chamber 2. On...

Embodiment 2

[0026] In Embodiment 1, as the device works, the spray liquid gradually accumulates on the top of the first piston 111, and a large amount of spray liquid accumulates on the first piston 111 and affects the normal movement of the first piston 111. Refer to Figure 1-6 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the flow guide mechanism includes a liquid collection box 201, the liquid collection box 201 is located between the porous packing layer 5 and the horizontal plate 112, and the liquid collection box 201 and the horizontal plate 112 The plate 112 is fixedly connected, there is a gap between the liquid collection box 201 and the inner wall of the processing chamber 1, and the liquid collection box 201 is provided with an infusion tube 202, the infusion tube 202 communicates with the liquid collection box 201, and one end of the infusion tube 202 communicates with the circulation pipeline 9, The infusion tube 202 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com