Drilling device for machining cast iron parts

A technology of drilling device and parts, applied in the field of iron casting processing, can solve the problems of easy injury and operator, low work efficiency and high risk factor, and achieve the effect of improving power utilization rate, improving work efficiency and ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

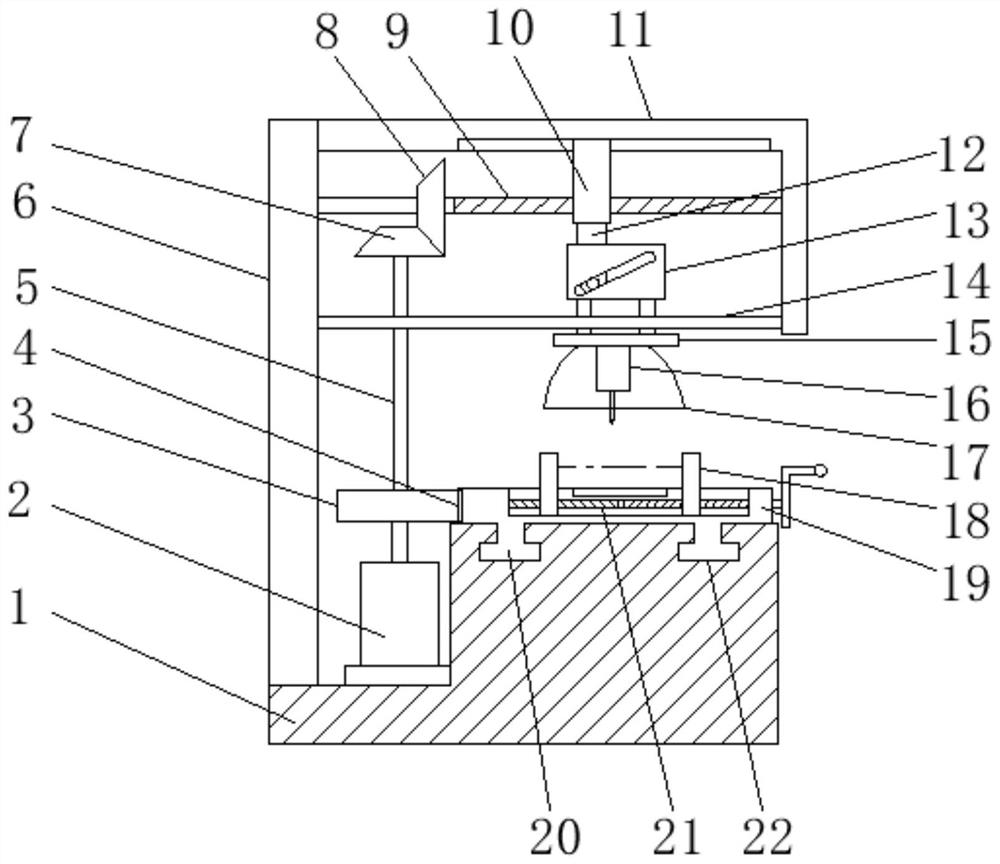

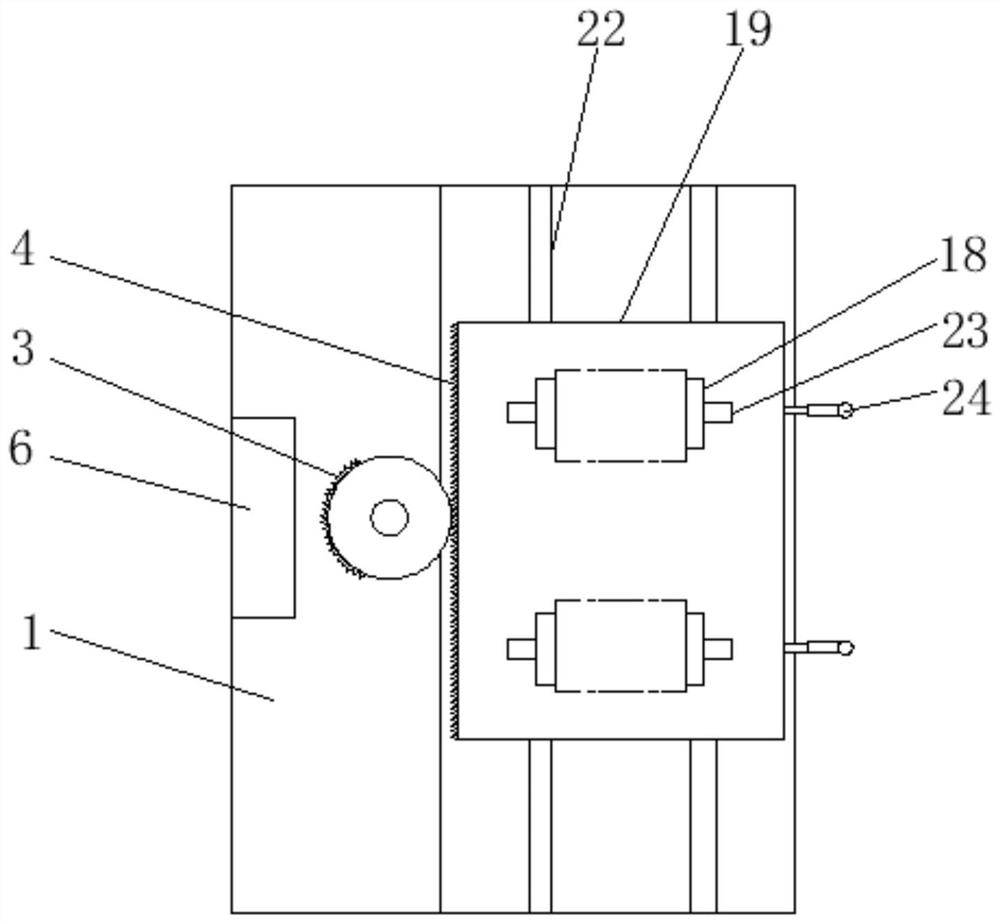

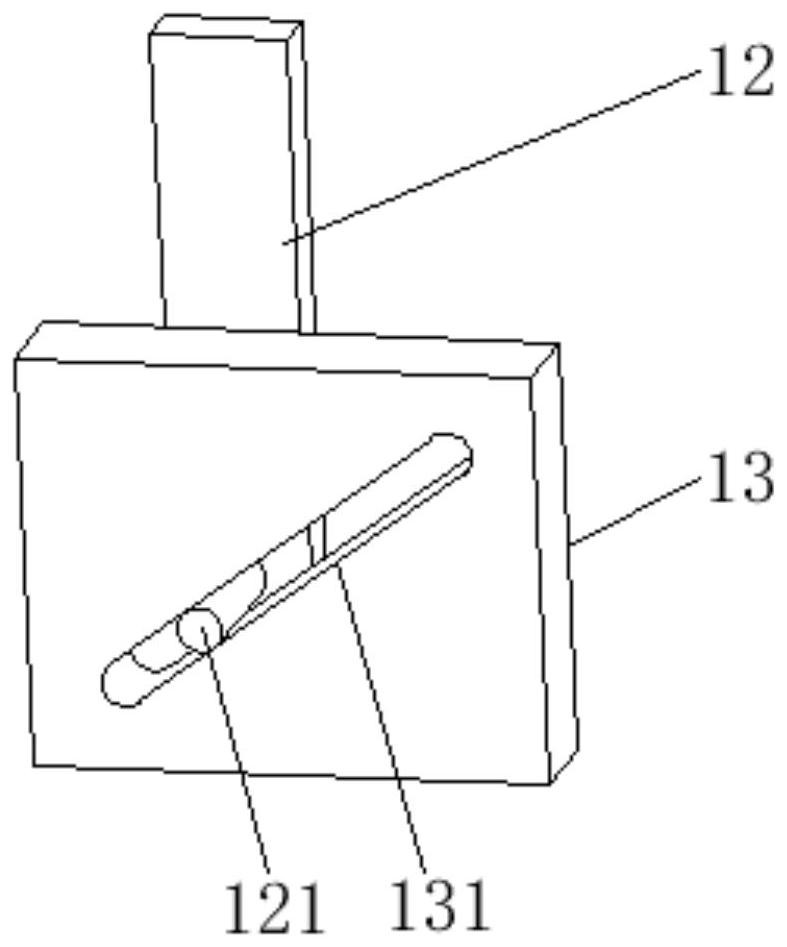

[0022] Embodiment one: refer to Figure 1~3 , in an embodiment of the present invention, a drilling device for processing cast iron parts, including a frame 1, a motor 2 and a column 6 are arranged on the left side of the upper end surface of the frame 1 to provide a power source, and the upper end of the column 6 is fixedly connected to a beam 11. The crossbeam 11 adopts an L-shaped structure, the output end of the motor 2 is fixedly connected with a guide post 5, the end of the guide post 5 close to the motor 2 is connected with a gear 3, and the gear 3 is meshed with a rack 4 to realize the conversion of circular motion into Linear movement, the right end of the rack 4 is fixedly connected with a workbench 19, thereby realizing the reciprocating movement of the workbench 19, the inside of the workbench 19 is provided with a second screw rod 21, and the second screw rod 21 is threadedly connected with a clamping block 18 to realize For the clamping of the workpiece, the clam...

Embodiment 2

[0029] Embodiment 2: This invention also provides another embodiment, which is improved on the basis of the above embodiment. The lower end of the workbench 19 is provided with a slider 20, and the slider 20 is set on the machine. The guide rail 22 on the upper end surface of the frame 1 is moved and connected to the frame 1, and the guide rail 22 adopts a T-shaped cross-section structure to ensure the stability of the reciprocating movement of the workbench 19.

[0030] When the device works, the workpiece is placed on the workbench 19, the handle 24 is turned, and the two-way clamping of the workpiece is realized through the second screw rod 21. At this time, the motor 2 is turned on, and the guide post 5 drives the gear 3 to rotate, and the gear 3 is meshed for transmission. The rack 4 drives the workbench 19 to reciprocate. At the same time, the first bevel gear 7 on the upper end of the guide column 5 engages and drives the second bevel gear 8. Driven by the first screw ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com