Method for overcoming explosion defect of 4140 steel tubing hanger body

An oil pipe hanging and body technology, applied in the field of workpiece forging, can solve problems such as pattern defects of folding knives, and achieve the effects of avoiding harmful tissue, reducing folding, and reducing knife patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail now in conjunction with accompanying drawing.

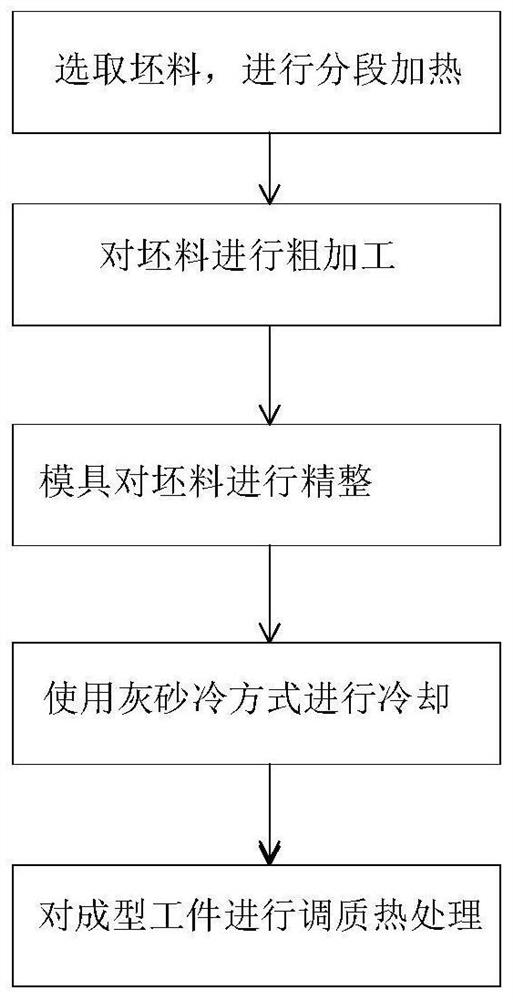

[0026] Such as figure 1 Shown, a kind of method of the present invention overcomes the defect of 4140 steel tubing hanger body bursting, comprises

[0027] Step 1: Select 350 square meters of 4140 blanks and put them into the heating furnace; set the temperature at 500±10°C, open the furnace door ajar, set the heating rate at 100°C / hour, and wait until the temperature in the furnace reaches 500±10°C , close the furnace door, and keep warm for two hours.

[0028] The temperature is set at 800±10°C, the heating rate is set at 50°C / hour, and when the temperature in the furnace reaches 800±10°C, keep warm for two hours.

[0029] The temperature is set at 1250±10°C, and the heating rate is set at 25°C / hour. When the temperature in the furnace reaches 1250±10°C, keep warm for two hours before leaving the oven.

[0030] Step 2: Rough machining of the blank, including elongat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com